All Engines: How-to Install header and downpipe

#51

Senior Member

Does anyone have more pics of the stock exhaust manifold?

I think this is one pic of a stock manifold, but is it more of a header or an exhaust log? Is it the same on the LNF 2.0?

I think this is one pic of a stock manifold, but is it more of a header or an exhaust log? Is it the same on the LNF 2.0?

#52

New Member

Join Date: 06-05-07

Location: bowmanville,Ontario

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

#54

Senior Member

Thread Starter

Join Date: 11-07-07

Location: SL,UT

Posts: 1,012

Likes: 0

Received 0 Likes

on

0 Posts

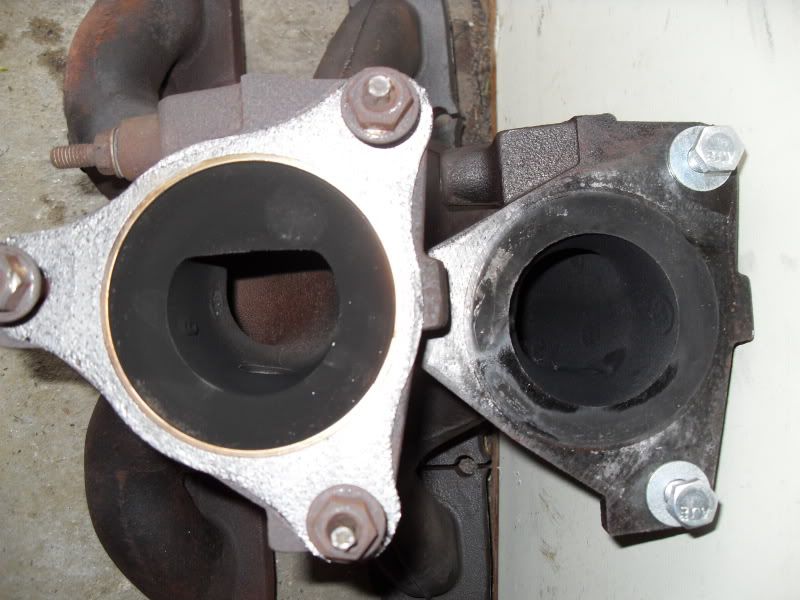

Here are a few pics of the LSJ manifold vs the L61 manifold

Lsj on top

Nice! feel free to ask any more questions!

#56

New Member

Join Date: 06-21-07

Location: Sioux Falls, South Dakota

Posts: 106

Likes: 0

Received 0 Likes

on

0 Posts

Personally I say yes. It reduces your under hood temps on the back side of the engine by a lot. You can't see the header anyway so just put the shield back on after bending it to fit and save yourself from getting things hotter then they need to be back there.

It also quiets the header noise some. Yes headers can make a wooshing noise that sounds kinda like an exhaust leak but isn't. They are tube stainless steel and don't block out sound like a thick manifold.

By the way you might want to note that the 2.4 auto is all done through the top side and is easy to do up there. You can't get to anything from the bottom on mine.

It also quiets the header noise some. Yes headers can make a wooshing noise that sounds kinda like an exhaust leak but isn't. They are tube stainless steel and don't block out sound like a thick manifold.

By the way you might want to note that the 2.4 auto is all done through the top side and is easy to do up there. You can't get to anything from the bottom on mine.

#57

Senior Member

Thread Starter

Join Date: 11-07-07

Location: SL,UT

Posts: 1,012

Likes: 0

Received 0 Likes

on

0 Posts

Personally I say yes. It reduces your under hood temps on the back side of the engine by a lot. You can't see the header anyway so just put the shield back on after bending it to fit and save yourself from getting things hotter then they need to be back there.

It also quiets the header noise some. Yes headers can make a wooshing noise that sounds kinda like an exhaust leak but isn't. They are tube stainless steel and don't block out sound like a thick manifold.

By the way you might want to note that the 2.4 auto is all done through the top side and is easy to do up there. You can't get to anything from the bottom on mine.

It also quiets the header noise some. Yes headers can make a wooshing noise that sounds kinda like an exhaust leak but isn't. They are tube stainless steel and don't block out sound like a thick manifold.

By the way you might want to note that the 2.4 auto is all done through the top side and is easy to do up there. You can't get to anything from the bottom on mine.

Added the last part to the how-to thanks!

#58

Senior Member

iTrader: (1)

Join Date: 10-23-05

Location: Pittsburgh, PA

Posts: 8,761

Likes: 0

Received 0 Likes

on

0 Posts

How long if you do it yourself with a jack and stands and how much if you get it installed at a place with a rack? Seems like 2-ish hours yourself. The guy I asked with a rack said 2 also, but it seems like it'd be less with a full rack.. But it's actually easier with an auto? That's a first.. lol

#59

Senior Member

iTrader: (1)

Join Date: 10-23-05

Location: Pittsburgh, PA

Posts: 8,761

Likes: 0

Received 0 Likes

on

0 Posts

So, I tried this today and............ WHAT A PAIN IN THE ASS. I thought I had more sockets than I did, but for not, the garage is super unorganized. I tried removing the heat shield first. The top two bolts on the block came off easy, but the top one "over" the header wouldn't budge. It was in a reasonably open area, but it took some stretching to get to it. I sprayed it several times and it didn't budge even a hair. Am I missing something? I realize using a socket could've helped a tad, but not for this. It still should've done something. Nope. ANY help..?????? Is the rest of it this hard..???

#62

Senior Member

iTrader: (1)

Join Date: 02-08-08

Location: Fayetteville/Linden, NC/Myrtle Beach, SC

Posts: 3,728

Likes: 0

Received 0 Likes

on

0 Posts

So, I tried this today and............ WHAT A PAIN IN THE ASS. I thought I had more sockets than I did, but for not, the garage is super unorganized. I tried removing the heat shield first. The top two bolts on the block came off easy, but the top one "over" the header wouldn't budge. It was in a reasonably open area, but it took some stretching to get to it. I sprayed it several times and it didn't budge even a hair. Am I missing something? I realize using a socket could've helped a tad, but not for this. It still should've done something. Nope. ANY help..?????? Is the rest of it this hard..???

#63

Senior Member

Thread Starter

Join Date: 11-07-07

Location: SL,UT

Posts: 1,012

Likes: 0

Received 0 Likes

on

0 Posts

How long if you do it yourself with a jack and stands and how much if you get it installed at a place with a rack? Seems like 2-ish hours yourself. The guy I asked with a rack said 2 also, but it seems like it'd be less with a full rack.. But it's actually easier with an auto? That's a first.. lol

So, I tried this today and............ WHAT A PAIN IN THE ASS. I thought I had more sockets than I did, but for not, the garage is super unorganized. I tried removing the heat shield first. The top two bolts on the block came off easy, but the top one "over" the header wouldn't budge. It was in a reasonably open area, but it took some stretching to get to it. I sprayed it several times and it didn't budge even a hair. Am I missing something? I realize using a socket could've helped a tad, but not for this. It still should've done something. Nope. ANY help..?????? Is the rest of it this hard..???

You are very welcome!

#64

Senior Member

iTrader: (1)

Join Date: 10-23-05

Location: Pittsburgh, PA

Posts: 8,761

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, I tried it several different times, and that bolt on the flat part just wouldn't budge. The good thing though is that I will be down there with him while he's doing the install, so we can only screw me price-wise so much. We shall see..

#65

Member

iTrader: (1)

Join Date: 03-01-08

Location: Port Jefferson Station, NY

Posts: 323

Likes: 0

Received 0 Likes

on

0 Posts

In essence... go in order torquing all 10 nuts down to 106in/lbs, followed by a 2nd pass, again in order, and make sure they're all at 106in/lbs

the 89in/lbs is for the exhaust shield studs.

the 89in/lbs is for the exhaust shield studs.

#66

Senior Member

iTrader: (1)

Join Date: 10-23-05

Location: Pittsburgh, PA

Posts: 8,761

Likes: 0

Received 0 Likes

on

0 Posts

So, after getting turned down by two local shops (in PA you need a cat, and I was just gonna run this thing ca-tless until I got it inspected) saying they'd get fined if they installed it, and after the smaller shop not being able to do me before the meet on Saturday, I decided to go to plan c and actually buy the proper sockets. To my surprise, the bolt on the heat-shield that I had an issue with came out. lol. BUT! I don't know if I'm the only one, but my heat-shield only had the top 3. There were no bottom two. I looked for them forever - nothing. I'm an auto 2.4. Probably one of those has something to do with it - likely the auto part. Regardless, I got that off and I was looking all around in there trying to figure out how to get to the bolts on the block for the stock header. Seems crazy difficult! The engine's still hot now, and I have to go to work, so I'm gonna do this tomorrow morning..

But, in saying "do it from the bottom" for the header, do you mean in the gap that is made after you remove the down-pipe? It seems like it'd be damn near impossible without removing the down-pipe first. Am I reading this right? Just want to get this all down before I start so there's no hiccups. So after letting the engine cool, it's simply bending weird and just getting to the bolts, right? That seems to basically be it. No more special moves or anything, just doing the 10 bolts on the block, 2 for the header to down-pipe, and then the 3 for the down-pipe to cat-back, correct? Seems to be that way. Sorry, it's just that I'm doing it myself with hand tools, a creeper, a set of stands, and a jack. I don't have much room to move under there, so I'm making sure ahead of time. lol

Please let me know.. Thanks!!

Also, will I get a CEL now too without a cat? I am gonna put one on for inspection, but not until then..

But, in saying "do it from the bottom" for the header, do you mean in the gap that is made after you remove the down-pipe? It seems like it'd be damn near impossible without removing the down-pipe first. Am I reading this right? Just want to get this all down before I start so there's no hiccups. So after letting the engine cool, it's simply bending weird and just getting to the bolts, right? That seems to basically be it. No more special moves or anything, just doing the 10 bolts on the block, 2 for the header to down-pipe, and then the 3 for the down-pipe to cat-back, correct? Seems to be that way. Sorry, it's just that I'm doing it myself with hand tools, a creeper, a set of stands, and a jack. I don't have much room to move under there, so I'm making sure ahead of time. lol

Please let me know.. Thanks!!

Also, will I get a CEL now too without a cat? I am gonna put one on for inspection, but not until then..

Last edited by averagewhiteboy; 05-27-2009 at 01:51 PM.

#67

Senior Member

Thread Starter

Join Date: 11-07-07

Location: SL,UT

Posts: 1,012

Likes: 0

Received 0 Likes

on

0 Posts

i might be a bit late, but i'm just reading this now, so here ya go, straight from GM! (via AllData):

In essence... go in order torquing all 10 nuts down to 106in/lbs, followed by a 2nd pass, again in order, and make sure they're all at 106in/lbs the 89in/lbs is for the exhaust shield studs.

the 89in/lbs is for the exhaust shield studs.

In essence... go in order torquing all 10 nuts down to 106in/lbs, followed by a 2nd pass, again in order, and make sure they're all at 106in/lbs

the 89in/lbs is for the exhaust shield studs.

the 89in/lbs is for the exhaust shield studs.So, after getting turned down by two local shops (in PA you need a cat, and I was just gonna run this thing ca-tless until I got it inspected) saying they'd get fined if they installed it, and after the smaller shop not being able to do me before the meet on Saturday, I decided to go to plan c and actually buy the proper sockets. To my surprise, the bolt on the heat-shield that I had an issue with came out. lol. BUT! I don't know if I'm the only one, but my heat-shield only had the top 3. There were no bottom two. I looked for them forever - nothing. I'm an auto 2.4. Probably one of those has something to do with it - likely the auto part. Regardless, I got that off and I was looking all around in there trying to figure out how to get to the bolts on the block for the stock header. Seems crazy difficult! The engine's still hot now, and I have to go to work, so I'm gonna do this tomorrow morning..

But, in saying "do it from the bottom" for the header, do you mean in the gap that is made after you remove the down-pipe? It seems like it'd be damn near impossible without removing the down-pipe first. Am I reading this right? Just want to get this all down before I start so there's no hiccups. So after letting the engine cool, it's simply bending weird and just getting to the bolts, right? That seems to basically be it. No more special moves or anything, just doing the 10 bolts on the block, 2 for the header to down-pipe, and then the 3 for the down-pipe to cat-back, correct? Seems to be that way. Sorry, it's just that I'm doing it myself with hand tools, a creeper, a set of stands, and a jack. I don't have much room to move under there, so I'm making sure ahead of time. lol

Please let me know.. Thanks!!

Also, will I get a CEL now too without a cat? I am gonna put one on for inspection, but not until then..

But, in saying "do it from the bottom" for the header, do you mean in the gap that is made after you remove the down-pipe? It seems like it'd be damn near impossible without removing the down-pipe first. Am I reading this right? Just want to get this all down before I start so there's no hiccups. So after letting the engine cool, it's simply bending weird and just getting to the bolts, right? That seems to basically be it. No more special moves or anything, just doing the 10 bolts on the block, 2 for the header to down-pipe, and then the 3 for the down-pipe to cat-back, correct? Seems to be that way. Sorry, it's just that I'm doing it myself with hand tools, a creeper, a set of stands, and a jack. I don't have much room to move under there, so I'm making sure ahead of time. lol

Please let me know.. Thanks!!

Also, will I get a CEL now too without a cat? I am gonna put one on for inspection, but not until then..

Really bro. don't stress it! Its not too hard. It may take you a while but you should get it.

And yes you will get a CEL from being catless..

#68

New Member

Join Date: 06-21-07

Location: Sioux Falls, South Dakota

Posts: 106

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for posting that! I'll add it to the how-to!

Honestly man, you are making this out to be a LOT harder than it is. All you have to do is remove the upper and lower heat shields, and 10 bolts in head, 3 on the manifold/DP connection and 2 for the DP to cat-back.

Really bro. don't stress it! Its not too hard. It may take you a while but you should get it.

And yes you will get a CEL from being catless..

Honestly man, you are making this out to be a LOT harder than it is. All you have to do is remove the upper and lower heat shields, and 10 bolts in head, 3 on the manifold/DP connection and 2 for the DP to cat-back.

Really bro. don't stress it! Its not too hard. It may take you a while but you should get it.

And yes you will get a CEL from being catless..

#71

Senior Member

Thread Starter

Join Date: 11-07-07

Location: SL,UT

Posts: 1,012

Likes: 0

Received 0 Likes

on

0 Posts