2.0 LNF Engine: How-To: Repair LNF cylinder head oil leaks

#26

#29

Senior Member

I tried to get my dealership to fix this but they were less than helpful. Infact they denied that i even had an oil leak and said it was just build up?? Even when i put my finger in there and pulled out with oil my finger and stuck it in his face he still said it was normal.

I looked at him called him a douche bag and went on my way. Fixed it myself, **** the warranty ill fix the **** myself unless its a pricey part.

I looked at him called him a douche bag and went on my way. Fixed it myself, **** the warranty ill fix the **** myself unless its a pricey part.

#33

Senior Member

iTrader: (1)

Is your LNF powered Cobalt SS leaking oil from the drivers side of the cylinder head? Has your local GM dealership been less than helpful on the matter? Well fret no more! In this how-to I'll attempt to guide you though fixing this once and for all. My car has been leak free now for a thousand miles and about a month, so I feel comfortable posting my method.

All of this originally came out of a 15+ page thread found here:

https://www.cobaltss.net/forums/2-0l-lnf-performance-tech-153/intake-camshaft-sensor-issue-153670/

And then a analysis thread of my leaky Cobalt here:

https://www.cobaltss.net/forums/2-0l-lnf-performance-tech-153/oil-leak-analysis-my-09-tc-186430/

Chances are your car is leaking from all 3 places too, and if its not now.... it might soon. I'd recommend just doing all 3, but if you want to cherry pick your specific issues be my guest. Also please note some of the pictures might seem out of order. Now that I've done this job, I would've taken the car apart differently. When I started I had no idea that my car was leaking from 3 places either.

A set of metric gear wrenches makes this job a snap, but any small metric tool kit should do.

1.) Remove the low pressure fuel pump relay, and start the car to relieve fuel pressure. The car will die on its own. Try to start it a couple more times to be sure the pressure is relieved. Consult your owners manual on the exact location of this relay, but its located in the engine bay fuse box. Once the car won't start, remove the negative battery terminal in the trunk. We're working with fuel and electronics here, best to be safe.

2.) Loosen t-bolt clamp on hot charge pipe from turbo, loosen & remove T30 torx on the hot charge pipe about midway (where it bolts to the bracket on the cylinder head) and then finally pull it off of the turbocharger. Carefully maneuver this pipe out of the way as you're working on the car. The lower rubber section will give you the freedom of movement you need without totally removing the pipe.

Should look something like this:

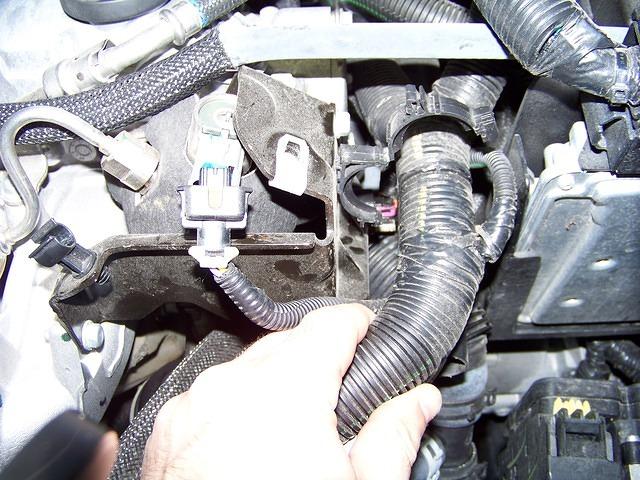

3.) Now, remove the bracket the hot pipe was bolted to via the T30. There are three 10MM holding this bracket to the cylinder head. You also need to disconnect the large wiring loom on the side. Use a flat blade and carefully undo the plastic wire loom holder from the bottom. You'll also need to remove what I believe is the evap purge line that runs over top of this bracket. Just simply disconnect it from the solenoid on the intake manifold and maneuver it out of your way. Also disconnect the harness from the high pressure fuel pump.

Once the bracket is removed, go ahead and also remove the sound isolator off the high pressure fuel pump too. You may also want to remove the larger vacuum hose that runs above the oil filter housing and goes to the front of the intake manifold and route it out of the way for now. Remove any wiring that looks like it might get in the way of the next steps, I can't remember everything I disconnected. Just mentally note what you did so the car will run again.

3.) Now, remove the bracket the hot pipe was bolted to via the T30. There are three 10MM holding this bracket to the cylinder head. You also need to disconnect the large wiring loom on the side. Use a flat blade and carefully undo the plastic wire loom holder from the bottom. You'll also need to remove what I believe is the evap purge line that runs over top of this bracket. Just simply disconnect it from the solenoid on the intake manifold and maneuver it out of your way. Also disconnect the harness from the high pressure fuel pump.

Once the bracket is removed, go ahead and also remove the sound isolator off the high pressure fuel pump too. You may also want to remove the larger vacuum hose that runs above the oil filter housing and goes to the front of the intake manifold and route it out of the way for now. Remove any wiring that looks like it might get in the way of the next steps, I can't remember everything I disconnected. Just mentally note what you did so the car will run again.

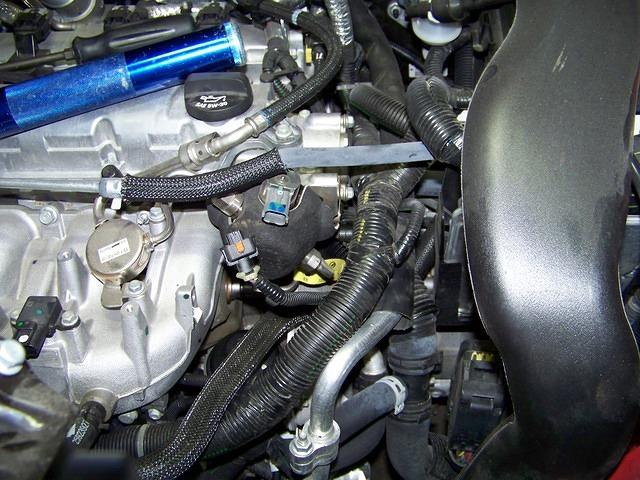

Should look something like these:

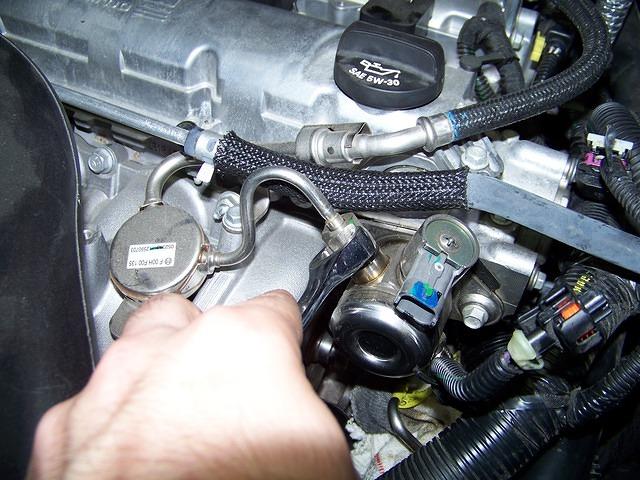

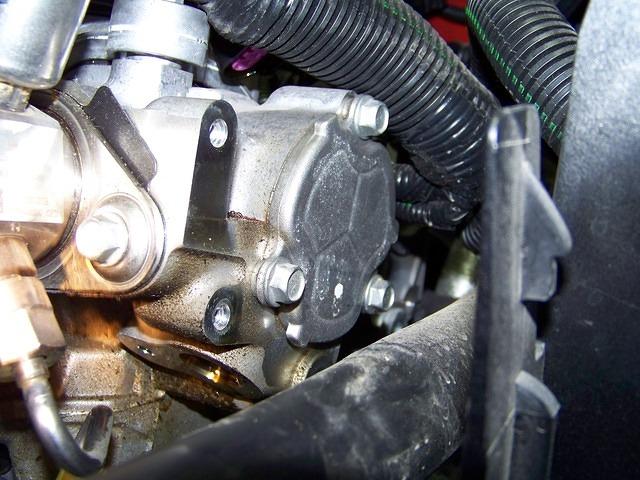

4.) Using a 17mm flare wrench, remove the feed line and pump output line from the high pressure fuel pump. You do NOT need to remove the pump output -> rail line, just loosen at the rail and it'll pivot out of the way. Have a rag ready to catch the fuel, you will spill some. Remove the two 10MM bolts that hold the round (I think this is a pulse dampner? but not sure) silver disc to the intake manifold and then the feed will move right out of the way. Remove the two 10MM bolts holding the fuel pump to the cyliner head and stow the pump in a safe place for now. I'd advice having a rag ready and under the pump to catch oil. Do NOT damage the gasket or o-ring on removal.

Should look something like these:

5.) Remove the 3 10MM bolts holding the intake cam end cap to the cylinder head. Not much to say about this one. Note which position the end cap was in, although it doesn’t appear to matter what orientation its installed from my eyeballing. Have your rag ready to catch oil from this too.

Should look something like these:

6.) Last but not least, remove the cam position sensor from below the high pressure fuel pump. It's held in with a 10MM bolt which you should remove. Then, CAREFULLY nudge the sensor out with a flat blade screw driver. Do NOT damage the o-ring upon removal.

Should look something like these:

Here is the sensor, its the black thing covered in grime

7.) CLEAN EVERYTHING UP. Use your favorite cleaning agents (mine was brake cleaner) and clean ALL components thoroughly. I mean down to the wiring, sensor, end plate, fuel pump and all mounting surfaces. Make sure you get the bore where the orings rest clean too. There was also a large amount of oil and gunk on my cylinder head and the top of my transmission. I would advise highly against getting any brake cleaner on the fuel pump gasket OR any of the o-rings. Carefully remove the o-rings with a tooth pick and set them aside. Just wipe those off with shop towels and don't lose them.

Now to stop these leaks we must use RTV. On my car I used Toyota FIPG (Form In Place Gasket) which has a work time of 15 minutes and run time of 1-2 hours. I don't advocate which RTV you use, just telling you what I used. Any quality RTV that is made to resist oil will do. ThreeBond comes highly recommended and Yamabond & Hondabond might also be good alternative. I would skip the el cheapo brands at the auto parts store and go with a high quality OEM approved sealer in general.

Here is a picture of a FIPG tube with the Toyota P/N on top. This P/N is specifically for oil usage on oil pans (Toyotas don’t use oil pan gaskets, just RTV bead), cam caps and other places where oil seepage must be stopped.

9.) Reassemble in the order we took it apart.

Run a nice small bead of RTV into the grove the o-ring rests in on the cam position sensor. Then slide the cleaned o-ring over the sensor and into this groove. I would then run another small bead of RTV over the o-ring. Reinsert the sensor into the cylinder head and torque the bolt to 10 ft lbs. If you don't have a torque wrench, snug it down but don't KILL it. 10 ft lbs isn’t a whole lot of torque

The pictures I took of this didn't come out, sorry about that.

10.) On the cam end plate, I chose to ditch the formed o-ring GM used from the factory. Take your cleaned end plate and insert the 3 bolts just about 5-10mm into it. There are nylon holders that will make reinstallation much easier this way. Otherwise you're bumbling around trying to center it. Run a bead of RTV into where the formed o-ring once was, and then compress this INTO that valley. Run another bead on top of that to form a nice 5mm bump. Reinstall the end cap onto the cylinder head and evenly torque the bolts to 10 ft lbs of torque.

After this sucker drys, I can promise you it'll never leak again.

Here are some pictures to make that procedure a little more clear:

11.) Now on to the fuel pump, we're getting close! First run a bead around the circular base of the fuel pump where it mates to the head. Look at the pump and you'll know exactly what I mean. Slide the cleaned or new gasket (note the orientation, the gasket says which side goes out/in) and compress it against that RTV. Then run another bead of RTV around that same circumference. This will make a nice RTV sandwich. Then, just like the cam position sensor, run a small bead of RTV into the groove where the o-ring rides. Gently slide on the cleaned o-ring and like before run a light bead on the o-ring. Gently insert the fuel pump into the cylinder head and tighten the two bolts to 10 ft lbs.

I forgot to take pictures before laying down the gasket, but hopefully these will help some:

12.) Now its time to put everything else back together. I'm not going to write much on this except to note the fuel lines going to the pump can be a bit tricky. Make sure you align them straight as possible before tightening the compression nuts. Technically, those lines are supposed to be replaced after being used just ONCE. I and others haven’t had any issues though, but don't blame me if your car bursts into flames. If I ever took them off again I'd likely replace them.

I would highly recommend letting the RTV dry for at LEAST 12 hours before driving, 24 if you can. Most say run in 1-2 hours, but why take the chance? Not worth having to do this job again.

I hope this how-to helps some of you, and if anyone thinks I missed something please PM or post and I'll edit the how-to. Until next time...

Since there has been questions about this lately I figured I would bumped it with the pics not 'CLICK HERE TO SEE MEH'

All of this originally came out of a 15+ page thread found here:

https://www.cobaltss.net/forums/2-0l-lnf-performance-tech-153/intake-camshaft-sensor-issue-153670/

And then a analysis thread of my leaky Cobalt here:

https://www.cobaltss.net/forums/2-0l-lnf-performance-tech-153/oil-leak-analysis-my-09-tc-186430/

Chances are your car is leaking from all 3 places too, and if its not now.... it might soon. I'd recommend just doing all 3, but if you want to cherry pick your specific issues be my guest. Also please note some of the pictures might seem out of order. Now that I've done this job, I would've taken the car apart differently. When I started I had no idea that my car was leaking from 3 places either.

A set of metric gear wrenches makes this job a snap, but any small metric tool kit should do.

1.) Remove the low pressure fuel pump relay, and start the car to relieve fuel pressure. The car will die on its own. Try to start it a couple more times to be sure the pressure is relieved. Consult your owners manual on the exact location of this relay, but its located in the engine bay fuse box. Once the car won't start, remove the negative battery terminal in the trunk. We're working with fuel and electronics here, best to be safe.

2.) Loosen t-bolt clamp on hot charge pipe from turbo, loosen & remove T30 torx on the hot charge pipe about midway (where it bolts to the bracket on the cylinder head) and then finally pull it off of the turbocharger. Carefully maneuver this pipe out of the way as you're working on the car. The lower rubber section will give you the freedom of movement you need without totally removing the pipe.

Should look something like this:

3.) Now, remove the bracket the hot pipe was bolted to via the T30. There are three 10MM holding this bracket to the cylinder head. You also need to disconnect the large wiring loom on the side. Use a flat blade and carefully undo the plastic wire loom holder from the bottom. You'll also need to remove what I believe is the evap purge line that runs over top of this bracket. Just simply disconnect it from the solenoid on the intake manifold and maneuver it out of your way. Also disconnect the harness from the high pressure fuel pump.

Once the bracket is removed, go ahead and also remove the sound isolator off the high pressure fuel pump too. You may also want to remove the larger vacuum hose that runs above the oil filter housing and goes to the front of the intake manifold and route it out of the way for now. Remove any wiring that looks like it might get in the way of the next steps, I can't remember everything I disconnected. Just mentally note what you did so the car will run again.

3.) Now, remove the bracket the hot pipe was bolted to via the T30. There are three 10MM holding this bracket to the cylinder head. You also need to disconnect the large wiring loom on the side. Use a flat blade and carefully undo the plastic wire loom holder from the bottom. You'll also need to remove what I believe is the evap purge line that runs over top of this bracket. Just simply disconnect it from the solenoid on the intake manifold and maneuver it out of your way. Also disconnect the harness from the high pressure fuel pump.

Once the bracket is removed, go ahead and also remove the sound isolator off the high pressure fuel pump too. You may also want to remove the larger vacuum hose that runs above the oil filter housing and goes to the front of the intake manifold and route it out of the way for now. Remove any wiring that looks like it might get in the way of the next steps, I can't remember everything I disconnected. Just mentally note what you did so the car will run again.

Should look something like these:

4.) Using a 17mm flare wrench, remove the feed line and pump output line from the high pressure fuel pump. You do NOT need to remove the pump output -> rail line, just loosen at the rail and it'll pivot out of the way. Have a rag ready to catch the fuel, you will spill some. Remove the two 10MM bolts that hold the round (I think this is a pulse dampner? but not sure) silver disc to the intake manifold and then the feed will move right out of the way. Remove the two 10MM bolts holding the fuel pump to the cyliner head and stow the pump in a safe place for now. I'd advice having a rag ready and under the pump to catch oil. Do NOT damage the gasket or o-ring on removal.

Should look something like these:

5.) Remove the 3 10MM bolts holding the intake cam end cap to the cylinder head. Not much to say about this one. Note which position the end cap was in, although it doesn’t appear to matter what orientation its installed from my eyeballing. Have your rag ready to catch oil from this too.

Should look something like these:

6.) Last but not least, remove the cam position sensor from below the high pressure fuel pump. It's held in with a 10MM bolt which you should remove. Then, CAREFULLY nudge the sensor out with a flat blade screw driver. Do NOT damage the o-ring upon removal.

Should look something like these:

Here is the sensor, its the black thing covered in grime

7.) CLEAN EVERYTHING UP. Use your favorite cleaning agents (mine was brake cleaner) and clean ALL components thoroughly. I mean down to the wiring, sensor, end plate, fuel pump and all mounting surfaces. Make sure you get the bore where the orings rest clean too. There was also a large amount of oil and gunk on my cylinder head and the top of my transmission. I would advise highly against getting any brake cleaner on the fuel pump gasket OR any of the o-rings. Carefully remove the o-rings with a tooth pick and set them aside. Just wipe those off with shop towels and don't lose them.

Now to stop these leaks we must use RTV. On my car I used Toyota FIPG (Form In Place Gasket) which has a work time of 15 minutes and run time of 1-2 hours. I don't advocate which RTV you use, just telling you what I used. Any quality RTV that is made to resist oil will do. ThreeBond comes highly recommended and Yamabond & Hondabond might also be good alternative. I would skip the el cheapo brands at the auto parts store and go with a high quality OEM approved sealer in general.

Here is a picture of a FIPG tube with the Toyota P/N on top. This P/N is specifically for oil usage on oil pans (Toyotas don’t use oil pan gaskets, just RTV bead), cam caps and other places where oil seepage must be stopped.

9.) Reassemble in the order we took it apart.

Run a nice small bead of RTV into the grove the o-ring rests in on the cam position sensor. Then slide the cleaned o-ring over the sensor and into this groove. I would then run another small bead of RTV over the o-ring. Reinsert the sensor into the cylinder head and torque the bolt to 10 ft lbs. If you don't have a torque wrench, snug it down but don't KILL it. 10 ft lbs isn’t a whole lot of torque

The pictures I took of this didn't come out, sorry about that.

10.) On the cam end plate, I chose to ditch the formed o-ring GM used from the factory. Take your cleaned end plate and insert the 3 bolts just about 5-10mm into it. There are nylon holders that will make reinstallation much easier this way. Otherwise you're bumbling around trying to center it. Run a bead of RTV into where the formed o-ring once was, and then compress this INTO that valley. Run another bead on top of that to form a nice 5mm bump. Reinstall the end cap onto the cylinder head and evenly torque the bolts to 10 ft lbs of torque.

After this sucker drys, I can promise you it'll never leak again.

Here are some pictures to make that procedure a little more clear:

11.) Now on to the fuel pump, we're getting close! First run a bead around the circular base of the fuel pump where it mates to the head. Look at the pump and you'll know exactly what I mean. Slide the cleaned or new gasket (note the orientation, the gasket says which side goes out/in) and compress it against that RTV. Then run another bead of RTV around that same circumference. This will make a nice RTV sandwich. Then, just like the cam position sensor, run a small bead of RTV into the groove where the o-ring rides. Gently slide on the cleaned o-ring and like before run a light bead on the o-ring. Gently insert the fuel pump into the cylinder head and tighten the two bolts to 10 ft lbs.

I forgot to take pictures before laying down the gasket, but hopefully these will help some:

12.) Now its time to put everything else back together. I'm not going to write much on this except to note the fuel lines going to the pump can be a bit tricky. Make sure you align them straight as possible before tightening the compression nuts. Technically, those lines are supposed to be replaced after being used just ONCE. I and others haven’t had any issues though, but don't blame me if your car bursts into flames. If I ever took them off again I'd likely replace them.

I would highly recommend letting the RTV dry for at LEAST 12 hours before driving, 24 if you can. Most say run in 1-2 hours, but why take the chance? Not worth having to do this job again.

I hope this how-to helps some of you, and if anyone thinks I missed something please PM or post and I'll edit the how-to. Until next time...

Since there has been questions about this lately I figured I would bumped it with the pics not 'CLICK HERE TO SEE MEH'

Last edited by steddy2112; 05-26-2010 at 07:24 AM. Reason: Automerged Doublepost

#37

Senior Member

Thread Starter

I put links to the pics is because I pay per GB xfer'd on that host.

So thanks for costing me like $0.30

So thanks for costing me like $0.30

Last edited by Gimpster; 11-06-2010 at 04:51 PM. Reason: Automerged Doublepost

#41

New Member

iTrader: (1)

Join Date: 07-07-07

Location: b-wick GA

Posts: 163

Likes: 0

Received 0 Likes

on

0 Posts

Service Information

2008 Chevrolet Cobalt | Cobalt, G5 VIN A Service Manual | Document ID: 2371867

--------------------------------------------------------------------------------

#09-06-01-014: Oil Leak by High Pressure Fuel Pump (Reseal Camshaft Cap) - (Dec 3, 2009)

Subject:

Oil Leak by High Pressure Fuel Pump (Reseal Camshaft Cap)

Models:

2007-2009 Chevrolet Cobalt SS, HHR SS

2007-2009 Pontiac Solstice GXP

2007-2009 Saturn SKY Redline

2008-2009 Opel GT

2008 Daewoo G2X

Equipped with a RPO LNF Engine

Please Refer to GMVIS

--------------------------------------------------------------------------------

Condition

Some customers may comment on an oil leak.

Upon further investigation, a technician may find oil leaking from the high pressure fuel pump area.

Cause

This condition may be caused by a camshaft cap that is not sealed correctly to the cylinder head, causing oil to leak out.

Correction

1.

Verify the customer's concern.

2.

Remove the fuel pump. Refer to Fuel Pump Removal in SI.

3.

Remove the camshaft cover. Refer to Camshaft Cover Removal in SI.

4.

Remove the camshaft cap (1). Remove all excess sealing material from both surfaces.

Note: It is critical during installation to ensure the bearing rear cap and cylinder head alignment is correct and the mating surfaces are flush.

•

Ensure that all sealing material has been removed from the components and the sealing surfaces are clean and free of contamination prior to applying the sealer.

•

Install and align the rear cap within 20 minutes of applying the sealer.

5.

Apply a 2.5 mm (0.1 in) bead of sealer, GM P/N 12378521 (in Canada, use P/N 88901148) to the cylinder head at the number 6 intake camshaft rear cap mating surface.

Note: Apply the sealer to all locations centrally locating the bead on the rail.

•

Run the bead to 5 mm (0.2 in), dimension “a”, as shown.

•

Where the cap ends on the perimeter rail, extend bead approximately 4 mm (0.2 in) beyond edge of cap.

•

Run bead, dimension “c”, 32 mm (1.3 in) from the edge of the cylinder head as shown.

•

Run bead, dimension “b”, 20 mm (0.8 in) from edge of cylinder head as shown.

6.

Install the number 6 intake camshaft rear cap.

6.1

Tighten the cap bolts evenly to 5 N·m(44 lb in).

6.2

Tighten the cap bolts evenly to 10 N·m(89 lb in).

6.3

Back the cap bolts out 120 degrees.

6.4

Tighten the cap bolts evenly a final pass to 10 N·m(89 lb in).

7.

Install the camshaft cover and gasket, GM P/N 12609291. Refer to Camshaft Cover Installation in SI.

8.

Install the fuel pump. Refer to Fuel Pump Installation in SI.

Important: When installing the fuel pump, install a NEW high pressure fuel pump O-ring (GM P/N 12600313), high pressure fuel pump gasket-to-cylinder head (GM P/N12595951) and high pressure fuel pipe (GM P/N12615401).

Parts Information

Part Number

Description

12609291

Camshaft Cover Gasket

12595951

Gasket, High Pressure Fuel Pump Gasket

12600313

High Pressure Fuel Pump O-Ring

12615401

High Pressure Fuel Pipe

12378521 (U.S.)

88901148 (Canada)

Silicone

Warranty Information

For vehicles repaired under warranty, use:

Labor Operation

Description

Labor Time

J7549*

Reseal Camshaft Cap

2.6 hrs

*This is a unique labor operation for bulletin use only. It will not be published in the Labor Time Guide

GM bulletins are intended for use by professional technicians, NOT a "do-it-yourselfer". They are written to inform these technicians of conditions that may occur on some vehicles, or to provide information that could assist in the proper service of a vehicle. Properly trained technicians have the equipment, tools, safety instructions, and know-how to do a job properly and safely. If a condition is described, DO NOT assume that the bulletin applies to your vehicle, or that your vehicle will have that condition. See your GM dealer for information on whether your vehicle may benefit from the information.

WE SUPPORT VOLUNTARY TECHNICIAN CERTIFICATION

© 2012 General Motors. All rights reserved.

2008 Chevrolet Cobalt | Cobalt, G5 VIN A Service Manual | Document ID: 2371867

--------------------------------------------------------------------------------

#09-06-01-014: Oil Leak by High Pressure Fuel Pump (Reseal Camshaft Cap) - (Dec 3, 2009)

Subject:

Oil Leak by High Pressure Fuel Pump (Reseal Camshaft Cap)

Models:

2007-2009 Chevrolet Cobalt SS, HHR SS

2007-2009 Pontiac Solstice GXP

2007-2009 Saturn SKY Redline

2008-2009 Opel GT

2008 Daewoo G2X

Equipped with a RPO LNF Engine

Please Refer to GMVIS

--------------------------------------------------------------------------------

Condition

Some customers may comment on an oil leak.

Upon further investigation, a technician may find oil leaking from the high pressure fuel pump area.

Cause

This condition may be caused by a camshaft cap that is not sealed correctly to the cylinder head, causing oil to leak out.

Correction

1.

Verify the customer's concern.

2.

Remove the fuel pump. Refer to Fuel Pump Removal in SI.

3.

Remove the camshaft cover. Refer to Camshaft Cover Removal in SI.

4.

Remove the camshaft cap (1). Remove all excess sealing material from both surfaces.

Note: It is critical during installation to ensure the bearing rear cap and cylinder head alignment is correct and the mating surfaces are flush.

•

Ensure that all sealing material has been removed from the components and the sealing surfaces are clean and free of contamination prior to applying the sealer.

•

Install and align the rear cap within 20 minutes of applying the sealer.

5.

Apply a 2.5 mm (0.1 in) bead of sealer, GM P/N 12378521 (in Canada, use P/N 88901148) to the cylinder head at the number 6 intake camshaft rear cap mating surface.

Note: Apply the sealer to all locations centrally locating the bead on the rail.

•

Run the bead to 5 mm (0.2 in), dimension “a”, as shown.

•

Where the cap ends on the perimeter rail, extend bead approximately 4 mm (0.2 in) beyond edge of cap.

•

Run bead, dimension “c”, 32 mm (1.3 in) from the edge of the cylinder head as shown.

•

Run bead, dimension “b”, 20 mm (0.8 in) from edge of cylinder head as shown.

6.

Install the number 6 intake camshaft rear cap.

6.1

Tighten the cap bolts evenly to 5 N·m(44 lb in).

6.2

Tighten the cap bolts evenly to 10 N·m(89 lb in).

6.3

Back the cap bolts out 120 degrees.

6.4

Tighten the cap bolts evenly a final pass to 10 N·m(89 lb in).

7.

Install the camshaft cover and gasket, GM P/N 12609291. Refer to Camshaft Cover Installation in SI.

8.

Install the fuel pump. Refer to Fuel Pump Installation in SI.

Important: When installing the fuel pump, install a NEW high pressure fuel pump O-ring (GM P/N 12600313), high pressure fuel pump gasket-to-cylinder head (GM P/N12595951) and high pressure fuel pipe (GM P/N12615401).

Parts Information

Part Number

Description

12609291

Camshaft Cover Gasket

12595951

Gasket, High Pressure Fuel Pump Gasket

12600313

High Pressure Fuel Pump O-Ring

12615401

High Pressure Fuel Pipe

12378521 (U.S.)

88901148 (Canada)

Silicone

Warranty Information

For vehicles repaired under warranty, use:

Labor Operation

Description

Labor Time

J7549*

Reseal Camshaft Cap

2.6 hrs

*This is a unique labor operation for bulletin use only. It will not be published in the Labor Time Guide

GM bulletins are intended for use by professional technicians, NOT a "do-it-yourselfer". They are written to inform these technicians of conditions that may occur on some vehicles, or to provide information that could assist in the proper service of a vehicle. Properly trained technicians have the equipment, tools, safety instructions, and know-how to do a job properly and safely. If a condition is described, DO NOT assume that the bulletin applies to your vehicle, or that your vehicle will have that condition. See your GM dealer for information on whether your vehicle may benefit from the information.

WE SUPPORT VOLUNTARY TECHNICIAN CERTIFICATION

© 2012 General Motors. All rights reserved.

#47

New Member

iTrader: (1)

Join Date: 05-24-10

Location: New Castle, DE

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

Great how-to! Just did this with GM Adhesive from zzp and its all sealed up great! Thanks!

Thread

Thread Starter

Forum

Replies

Last Post

Jesse

Problems/Service/Maintenance

2

09-28-2015 12:51 PM