4x4 Rock Buggy TC 2.4 Build

#51

Junior Member

Thread Starter

I'm leaning toward the CBM so that I can build my intake lower and not have to worry about getting the oil filter out. But if I do that what happens with the oil cooler holes on the back of the stock housing? Do I build a block-off plate for them?

The following users liked this post:

patooyee (11-23-2015)

#55

Junior Member

Thread Starter

Just found this modification:

https://www.cobaltss.net/forums/2-0l...-where-314830/

This would solve so many issues for me. Anyone see any reason I shouldn't? (I think I'm going to need to be drunk the day I do this!)

https://www.cobaltss.net/forums/2-0l...-where-314830/

This would solve so many issues for me. Anyone see any reason I shouldn't? (I think I'm going to need to be drunk the day I do this!)

#56

Senior Member

iTrader: (1)

if it works better for your chassis i dont see a downside. however your going to have to strip the engine to a bare block and have it cleaned before and after the work. thats the reason i went with the cbm adapter over cutting the block for my swap, my engine is already together and i have no reason to pull it apart to do the mod. in mine the filter housing isnt really in the way, just cant get to it to change the filter

#57

Junior Member

Thread Starter

I finally got my 4t65 rebuilt today. Lack of shop-time for the holidays combined with problem after problem while I was inside of it resulted in the rebuild drawing out over the course of an entire friggen month. Pretty sure I have a good trans ready to go now. I started getting the Bates Engineering adapter plate ready to go:

There are immediately two issues created by the adapter. One obvious in that pic, the other not so much.

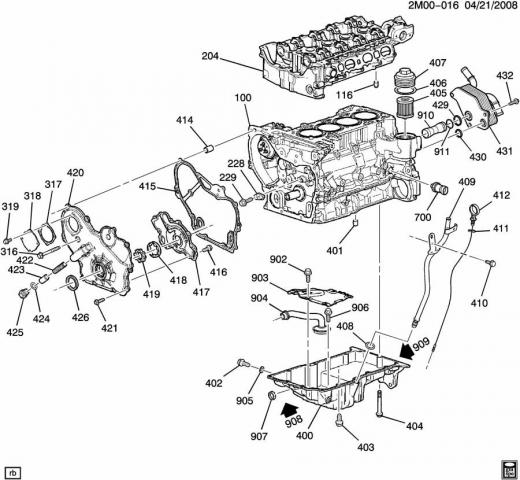

1. The obvious issue is the oil cooler port is partially covered by the adapter plate. I spoke to Ray Bates briefly about this. There are a couple options here. As previously discussed, I can lop off the oil filter housing and weld fittings to the block, run remote oil filter. Another is to tap the ports and plug them. Not sure what I am going to do yet, but after looking more closely at the space constraints I'm fairly certain that I won't need to cut the housing off for my intake.

2. The less obvious interference issue is that the t-stat housing doesn't clear the adapter either. Ray said that he normally makes a plate for the back of the water pump that has a hose fitting on it which then welds to the housing cover. This eliminates the coolant pipe and t-stat housing as well as the heater core hoses, none of which I woudl be running anyway. It also uses a block-off plate for the rectangular port where the t-stat housing used to be:

The only other coolant port on the engine at that point is the one on the side of the head.

So I guess coolant would come out the bottom of my radiator into the back of my water pump, through the engine, out the head, and back into the top of the radiator. Does that flow path sound right? Does anyone have a coolant flow diagram for an Ecotec for me to verify?

There are immediately two issues created by the adapter. One obvious in that pic, the other not so much.

1. The obvious issue is the oil cooler port is partially covered by the adapter plate. I spoke to Ray Bates briefly about this. There are a couple options here. As previously discussed, I can lop off the oil filter housing and weld fittings to the block, run remote oil filter. Another is to tap the ports and plug them. Not sure what I am going to do yet, but after looking more closely at the space constraints I'm fairly certain that I won't need to cut the housing off for my intake.

2. The less obvious interference issue is that the t-stat housing doesn't clear the adapter either. Ray said that he normally makes a plate for the back of the water pump that has a hose fitting on it which then welds to the housing cover. This eliminates the coolant pipe and t-stat housing as well as the heater core hoses, none of which I woudl be running anyway. It also uses a block-off plate for the rectangular port where the t-stat housing used to be:

The only other coolant port on the engine at that point is the one on the side of the head.

So I guess coolant would come out the bottom of my radiator into the back of my water pump, through the engine, out the head, and back into the top of the radiator. Does that flow path sound right? Does anyone have a coolant flow diagram for an Ecotec for me to verify?

#59

Senior Member

iTrader: (1)

the coolant is pulled in through the water pump, flows through the block, into the head, and out the water outlet on the head.

here is my solution to the whole thing.

i removed the t-stat and all the crap bolted to the back of the block. in the bottom of that elbow i have a remote t-stat housing welded into it, it unscrews to put the t-stat in. i have added some bungs to it, my heater return goes into there as well as a temp sensor and my turbo coolant return, more on that later. now on the rear of the block i did this

so that is whats left of the factory t-stat housing after i cut everything else off it. another temp sensor, outlet for the heater, and my turbo coolant feed (on bottom, not shown).

one thing to keep in mind, you need some way for a small amount of coolant to bypass to keep from pressurizing the system when the t-stat is closed. coolant is always flowing through the block in an ecotec,. factory ecotec does this in 2 ways, 1) there is a small bleed hole in the t-stat housing between the port on the back of the block and were the coolant transfer tube (big one going to the water pump) is, this is small, around 1/8". 2) the heater system, like in all newer cars, is a blend door system, so there is always coolant flowing through the heater core. in my application my heater core is a shut off valve style, so when the heats off i need a way for coolant to flow. what ive done is run a line from the port on the back of the block up to the turbo, and back to the water neck just before it enters the water pump.

here is my solution to the whole thing.

i removed the t-stat and all the crap bolted to the back of the block. in the bottom of that elbow i have a remote t-stat housing welded into it, it unscrews to put the t-stat in. i have added some bungs to it, my heater return goes into there as well as a temp sensor and my turbo coolant return, more on that later. now on the rear of the block i did this

so that is whats left of the factory t-stat housing after i cut everything else off it. another temp sensor, outlet for the heater, and my turbo coolant feed (on bottom, not shown).

one thing to keep in mind, you need some way for a small amount of coolant to bypass to keep from pressurizing the system when the t-stat is closed. coolant is always flowing through the block in an ecotec,. factory ecotec does this in 2 ways, 1) there is a small bleed hole in the t-stat housing between the port on the back of the block and were the coolant transfer tube (big one going to the water pump) is, this is small, around 1/8". 2) the heater system, like in all newer cars, is a blend door system, so there is always coolant flowing through the heater core. in my application my heater core is a shut off valve style, so when the heats off i need a way for coolant to flow. what ive done is run a line from the port on the back of the block up to the turbo, and back to the water neck just before it enters the water pump.

#60

Junior Member

Thread Starter

That's cool Sharkey. I would probably do something similar if I cared about keeping a t-stat or a heater core. I was already thinking about ways to eliminate my t-stat anyway.

#61

Senior Member

iTrader: (1)

there is no benifit to eliminating the t-stat, in fact it can cause more issues. the engine is designed to run at a specific temp, its going to get there no matter what, it will just take longer. the other downside is the t-stat acts as a regulator to slow the coolant down so it can properly absorb the heat from the engine, if the coolant flows too fast the cooling system actually becomes inefficient because the heat isnt transfering into the coolant, and that can cause hot spots in the block and head.

#62

Junior Member

Thread Starter

I understand your concerns but I'm aware of the side effects and know what I'm doing in regards to the t-stat. I've eliminated the t-stat in many engines and never had any ill side effects.

#63

Junior Member

Thread Starter

The 3/8 NPT tap worked well on the smaller port but 1/2 was too small and 3/4 was too big for the bigger port after the sleeve came out. I didn't have a 59/64 drill to drill it out so I just made a small plug and welded it, ground it smooth to let the adapter sit flush.

Finally got the adapter mated to the engine. I had to do some drilling / grinding on the block behind these two holes in case the transmission bolts went all the way through. I didn't want them to bottom out and then strip the adapter.

I started machining a snout extender for the torque converter to make up for the 16mm added length of the adapter but my lathe broke down in the process. I'm trying not to allow hold-ups like this to set me back in time so I drew up a quick model in Solidworks and sent the files out to someone I know with a CNC lathe. I'm having some parts made for my axle housings at the same time. Hope to have it back next week.

Finally got the adapter mated to the engine. I had to do some drilling / grinding on the block behind these two holes in case the transmission bolts went all the way through. I didn't want them to bottom out and then strip the adapter.

I started machining a snout extender for the torque converter to make up for the 16mm added length of the adapter but my lathe broke down in the process. I'm trying not to allow hold-ups like this to set me back in time so I drew up a quick model in Solidworks and sent the files out to someone I know with a CNC lathe. I'm having some parts made for my axle housings at the same time. Hope to have it back next week.

#64

Junior Member

Thread Starter

I've seen people on sports compact forums saying how a 4t65e would never ever in a 100 years fit in a compact car because it was so much bigger. I snapped these pics while I had both rebuilt, clean, and sitting on the floor next to each other. I know that brackets, mounts, etc can be tricky for people who don't / can't fabricate so I understand that. But I would be willing to bet that one could make a 65e fit anywhere a 45e can with a small amount of ingenuity and fab:

#65

Junior Member

Thread Starter

Snout extender for the torque converter, presses into crank shaft, makes up for the length of the adapter and pilots the TC:

Spacers made for the "feet" of the converter, taped and welded on. The "snout" of the converter has to have about 1/16" grinded off to work:

The engine block had to be trimmed in the following areas to fit the transmission. (This was a PITA and I should have done it before I rebuilt the trans when I had the empty case available.)

Closeup of the engine to trans clearance after installation with trimming:

AFAIK these are the first pictures on the internet of a 4t65 successfully mated to an Ecotec:

Spacers made for the "feet" of the converter, taped and welded on. The "snout" of the converter has to have about 1/16" grinded off to work:

The engine block had to be trimmed in the following areas to fit the transmission. (This was a PITA and I should have done it before I rebuilt the trans when I had the empty case available.)

Closeup of the engine to trans clearance after installation with trimming:

AFAIK these are the first pictures on the internet of a 4t65 successfully mated to an Ecotec:

#67

Senior Member

iTrader: (1)

nice job.

not sure if you planned to make a brace to bolt between the diff cover bolts and the engine block like it would have had when bolted to the v6. id suggest it, years ago i replaced a cracked 4t65e case in a montana that we suspected broke because the diff brace was left off. thats the one and only cracked 4t65e case id ever seen.

not sure if you planned to make a brace to bolt between the diff cover bolts and the engine block like it would have had when bolted to the v6. id suggest it, years ago i replaced a cracked 4t65e case in a montana that we suspected broke because the diff brace was left off. thats the one and only cracked 4t65e case id ever seen.

#68

Junior Member

Thread Starter

nice job.

not sure if you planned to make a brace to bolt between the diff cover bolts and the engine block like it would have had when bolted to the v6. id suggest it, years ago i replaced a cracked 4t65e case in a montana that we suspected broke because the diff brace was left off. thats the one and only cracked 4t65e case id ever seen.

not sure if you planned to make a brace to bolt between the diff cover bolts and the engine block like it would have had when bolted to the v6. id suggest it, years ago i replaced a cracked 4t65e case in a montana that we suspected broke because the diff brace was left off. thats the one and only cracked 4t65e case id ever seen.

#70

Junior Member

Thread Starter

Question that I think I already know the answer to:

I want an Ecotec on an engine stand to fabricate brackets around. It doesn't need to be a good running engine, internally it can be completely dogged out for all I care. There is a 2.2 L61 near me for $150. All the block patterns and bolt holes should be the same as my LE5, correct? Mainly referring to timing cover and intake flange ...

I want an Ecotec on an engine stand to fabricate brackets around. It doesn't need to be a good running engine, internally it can be completely dogged out for all I care. There is a 2.2 L61 near me for $150. All the block patterns and bolt holes should be the same as my LE5, correct? Mainly referring to timing cover and intake flange ...

#72

Junior Member

Thread Starter

No, I just haven't got around to pulling that stuff off yet.

These little engines are so cool. They're just like little LS2's. They share a lot of the same parts and designs.

These little engines are so cool. They're just like little LS2's. They share a lot of the same parts and designs.

#73

Question that I think I already know the answer to:

I want an Ecotec on an engine stand to fabricate brackets around. It doesn't need to be a good running engine, internally it can be completely dogged out for all I care. There is a 2.2 L61 near me for $150. All the block patterns and bolt holes should be the same as my LE5, correct? Mainly referring to timing cover and intake flange ...

I want an Ecotec on an engine stand to fabricate brackets around. It doesn't need to be a good running engine, internally it can be completely dogged out for all I care. There is a 2.2 L61 near me for $150. All the block patterns and bolt holes should be the same as my LE5, correct? Mainly referring to timing cover and intake flange ...

The following users liked this post:

patooyee (12-14-2015)

#75

Junior Member

Thread Starter

I seem to recall that on some of the LS engines when you do this you have to use the o-ring from the neck on the cap instead of the original one on the cap. Maybe Ecotecs are the same?

Moderator

Moderator