Powell's take on replacing bad control arm bushings.

#33

The malibu solid insert doesnt fit properly in an alloy arm and its a weak pos anyway.

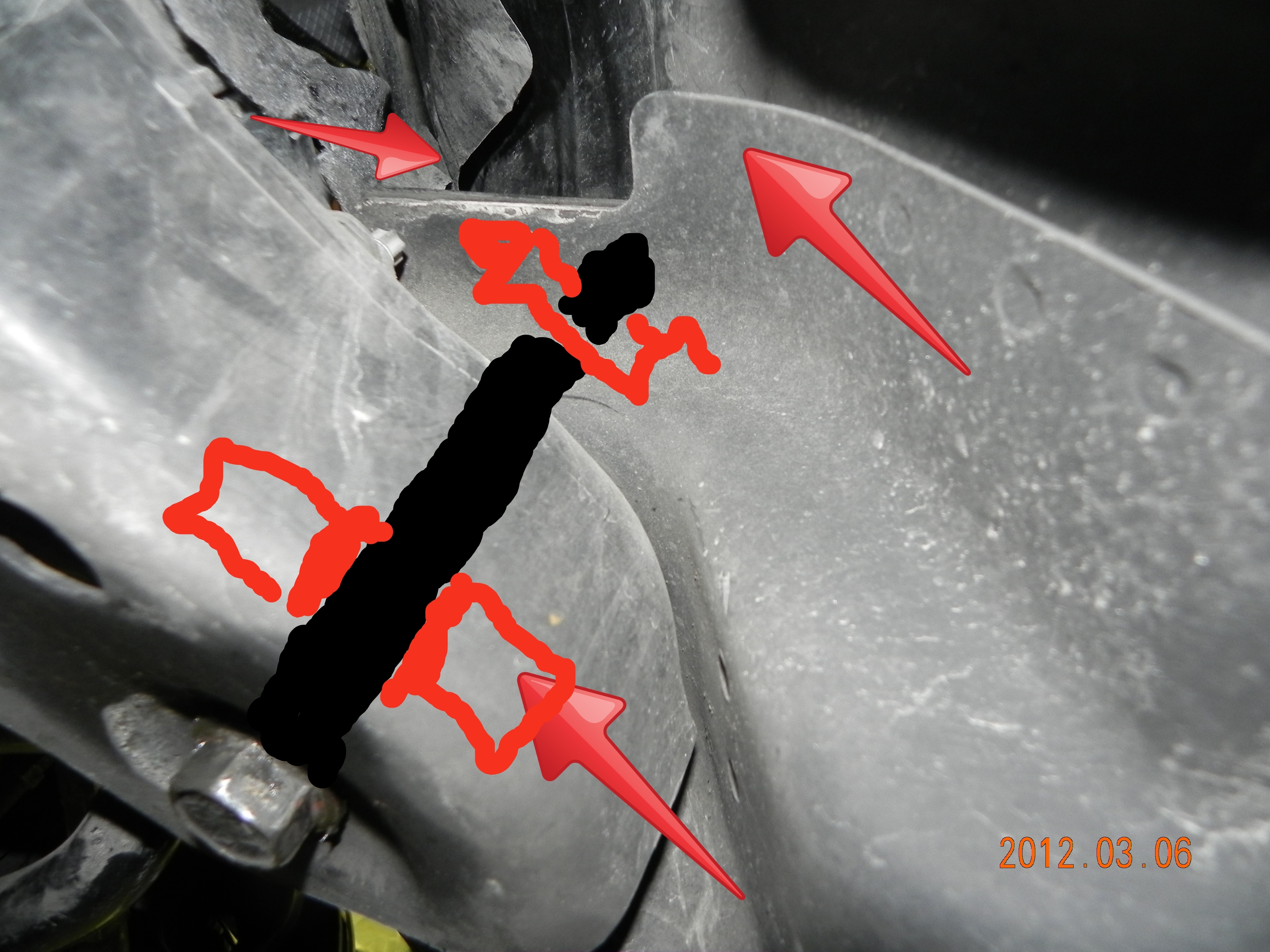

trailing control arm bolt/cradle bolt/

malibu cab in an 06 ss alloy arm . meh.

#34

Yes, John replaced my (separated and torn) CAB's yesterday, and that eliminated my front brake vibration.

My car had been suffering from pulsating brakes for months now (it was next on my list of things to address), and I thought it was either hot spots on the rotors, or warped rotors from improper wheel nut torque when my snow tires were changed over.

Needless to say, I saved some money on not replacing rotors unnecessarily (which is a good thing!).

My car had been suffering from pulsating brakes for months now (it was next on my list of things to address), and I thought it was either hot spots on the rotors, or warped rotors from improper wheel nut torque when my snow tires were changed over.

Needless to say, I saved some money on not replacing rotors unnecessarily (which is a good thing!).

#36

^^^^lol@sharkey good picture. The arm moves in and out as it travels up and down at the trailing position and poly wont work. In fact poly is a pretty poor material for suspension bushings, although conventional wisdom regards that as an upgrade. The SAAB community love buying that poly stuff for their car for suspension and cradle mounts ( its cheep). There are better composite materials but they are more expensive for sure.

At the end of the day our replacement trailing cab is a way better part. I am currently negotiating with the vendor a big buy as it is possible this joint could go out of production. ugh.

One thing to note: when servicing your arms or struts, the new CAB WILL NOT allow the same amount of " over travel"the stock CAB permits, so you MUST release the leading cab some of the way on its bolts in order to change struts, once you upgrade. No big deal.

also the book calls for 75 ft lbs + 180 degrees for the cradle bolt. Use 145 ft lbs but please torque it. Also the rear sway bar we sell, very important to torque to 50 ft lbs. As the rear bar fastener nut plates are mechanical lock nuts, its possible to tighten them by hand and figure you are good. Without a torque wrench you wont be correct. Check it out.

At the end of the day our replacement trailing cab is a way better part. I am currently negotiating with the vendor a big buy as it is possible this joint could go out of production. ugh.

One thing to note: when servicing your arms or struts, the new CAB WILL NOT allow the same amount of " over travel"the stock CAB permits, so you MUST release the leading cab some of the way on its bolts in order to change struts, once you upgrade. No big deal.

also the book calls for 75 ft lbs + 180 degrees for the cradle bolt. Use 145 ft lbs but please torque it. Also the rear sway bar we sell, very important to torque to 50 ft lbs. As the rear bar fastener nut plates are mechanical lock nuts, its possible to tighten them by hand and figure you are good. Without a torque wrench you wont be correct. Check it out.

#37

Senior Member

iTrader: (6)

75ft lbs plus 180degrees is the same as 145ft lbs correct? I doubt man ppl have a torque wrench that reads accuratly at 145ft lbs, my torque wrench tops out at 150ft lbs and I'm sure its like most things the accuracy craps out near the low end and high end of the range.

#42

for the folks who think gudentite is enough, not always by a long shot

#43

I noticed a huge difference once I installed mine. Removing was a piece of cake, as mine weren't seized.

however re-installing them? That was a whole different story lol

however re-installing them? That was a whole different story lol

#45

Senior Member

iTrader: (6)

Def would be worth buying a better range torque wrench before I buy these from you. I was just thinking from an instrument management stand point, the engineer side of me coming out once 90% of a range is reached I want to move to the next

Klien tools for the most part are still made state side. Some Craftsman are made here still.

Klien tools for the most part are still made state side. Some Craftsman are made here still.

#46

Senior Member

iTrader: (4)

Yup. Here's a great source for finding out where to spend your money so it doesn't go into building Chinese aircraft carriers: Still Made in USA.com - American-Made Tools

I'm more American than most when it comes to this stuff. And to think I'm not even a US citizen ;-)

I'm more American than most when it comes to this stuff. And to think I'm not even a US citizen ;-)

Last edited by colodude18; 08-22-2013 at 06:00 PM.

#47

Senior Member

iTrader: (1)

Yup. Here's a great source for finding out where to spend your money so it doesn't go into building Chinese aircraft carriers: Still Made in USA.com - American-Made Tools

I'm more American than most when it comes to this stuff. And to think I'm not even a US citizen (YET) ;-)

I'm more American than most when it comes to this stuff. And to think I'm not even a US citizen (YET) ;-)

That's a pretty big joke. Almost everything you use on a daily basis is made elsewhere. Support companies that make quality products, that way in the future you can get quality products from them. Otherwise, you will get some of the **** poor stuff that even "hard" working American's made.

Our economy is not going to get any better because of that buying tactic. When now are in a global economy.

#48

Senior Member

iTrader: (4)

So basically we shouldn't use anything because it's not made in China?

That's a pretty big joke. Almost everything you use on a daily basis is made elsewhere. Support companies that make quality products, that way in the future you can get quality products from them. Otherwise, you will get some of the **** poor stuff that even "hard" working American's made.

Our economy is not going to get any better because of that buying tactic. When now are in a global economy.

That's a pretty big joke. Almost everything you use on a daily basis is made elsewhere. Support companies that make quality products, that way in the future you can get quality products from them. Otherwise, you will get some of the **** poor stuff that even "hard" working American's made.

Our economy is not going to get any better because of that buying tactic. When now are in a global economy.

The reality is that most people will buy cheap Chinese products over more expensive quality US products. Those are typically also the people that yell the loudest that their jobs are shipped overseas.

Me, I'm willing to pay even a considerable premium for products that are still made in the US. I am aware there is a global economy. There has been for some decades. But the reality is that people are affected more by their local economy, thus the need to support that local economy.

It's true that many products are ONLY made in certain geographies, most notably China. There's little choice if you want to buy LED light bulbs to name an example. I'm not ignoring that fact, just trying to make people aware that they have a choice to make.

#49

I have first hand experience with this.

Bingo.

#50

well I am happy to say that YYZ springs are made in USA!! The best. Inspired by Wangspeed. Our sway bars are made in Canaduh from German sourced Chrome Moly purchased from a USA distributor. Inspired by Time Attack but a pure Powell idea.

Same for rotated mounts made in Canada. Inserts from....USA/Mexico/India...what month is it? China prolly next.

Our trap door pans made in Canada from OEM pans made in Israel, China or Chechoslovakia. I never know.

Our tow hooks are made in Canada of canadian steel with fasteners out of Indianapolis.

Our PCV upgrade setup was developed by me with engineering input from the USA, assembled in Canada. I suspect our Russell AN fittings are made in China. Our Mann Hummell seperators are.

OUr harness bars and UCR made in Canada, same thing applies for the Chrome Moly as above the DOM tube s canadian made.

etc. I am with Colordude but agree with USMC, and will say its very hard to match some prices of off shore stuff. 60% of the Camaro is made from parts sourced in China, the worlds largest car market.

and to all of you that buy our parts instead of the copies from other vendors here

thank you.

Same for rotated mounts made in Canada. Inserts from....USA/Mexico/India...what month is it? China prolly next.

Our trap door pans made in Canada from OEM pans made in Israel, China or Chechoslovakia. I never know.

Our tow hooks are made in Canada of canadian steel with fasteners out of Indianapolis.

Our PCV upgrade setup was developed by me with engineering input from the USA, assembled in Canada. I suspect our Russell AN fittings are made in China. Our Mann Hummell seperators are.

OUr harness bars and UCR made in Canada, same thing applies for the Chrome Moly as above the DOM tube s canadian made.

etc. I am with Colordude but agree with USMC, and will say its very hard to match some prices of off shore stuff. 60% of the Camaro is made from parts sourced in China, the worlds largest car market.

and to all of you that buy our parts instead of the copies from other vendors here

thank you.