max slope per volt of LNF ecu?

#1

Senior Member

Thread Starter

max slope per volt of LNF ecu?

is the max slope per volt of the LNF ecu only 102kpa?

my 5 bar sensor has a 129.7kpa slope per volt

so am I gonna be limited to only 4 bar?

thanks!

my 5 bar sensor has a 129.7kpa slope per volt

so am I gonna be limited to only 4 bar?

thanks!

#3

Senior Member

Thread Starter

I dont know, I haven't done this before.

Ryan's lsj boosted 58psi to get 891whp.

so a 4 bar will only be around 43psi

4 x 14.5 and subtract 14.7 = 43.3

even if my big turbo is a lil bit bigger than his, I'm not really sure if 43psi will be enough to get to my goals

Ryan's lsj boosted 58psi to get 891whp.

so a 4 bar will only be around 43psi

4 x 14.5 and subtract 14.7 = 43.3

even if my big turbo is a lil bit bigger than his, I'm not really sure if 43psi will be enough to get to my goals

#4

The max slope for the E69 ECU is 102.4 kpa per 5 volts, but you can shift the scale +-256 kpa.

The stock sensors are 55.68 kpa per 5v, and a -5% offset I think they are 2.5bar

The GMPP sensors are 65.88 kpa per 5v, and a -10% offset they are 3 bar

So your max slope of 102.4 would yield a 4.5 bar sensor with up to a +3% offset.

I would bench calibrate your 5bar sensor, to find its exact scaler and offset. I think you can make it work. May just need a small shift in the scale

Just curious Sky888 why aren't you asking this in the HPTForum?

I've calibrated and tuned for 3.5bar and 4bar sensors and the white paper specifications you get from Bosch aren't ever correct they can be off by 10% or more.

Hit me up by PM here or in the Kappa/Sky/Sol/HPT forums I'd be happy to help you with your project.

--Christian

The stock sensors are 55.68 kpa per 5v, and a -5% offset I think they are 2.5bar

The GMPP sensors are 65.88 kpa per 5v, and a -10% offset they are 3 bar

So your max slope of 102.4 would yield a 4.5 bar sensor with up to a +3% offset.

I would bench calibrate your 5bar sensor, to find its exact scaler and offset. I think you can make it work. May just need a small shift in the scale

Just curious Sky888 why aren't you asking this in the HPTForum?

I've calibrated and tuned for 3.5bar and 4bar sensors and the white paper specifications you get from Bosch aren't ever correct they can be off by 10% or more.

Hit me up by PM here or in the Kappa/Sky/Sol/HPT forums I'd be happy to help you with your project.

--Christian

#6

Sky,

remember the LNF has a volumetric efficiency over the LSJ that extra part of air that make it in because the fuel is injected after the valve closes, I'm not doing the math right now but its like 8% or 11%. Plus with the better fuel control and potential to run more timing, means hotter gasses and higher efficiency. My guess is you will have the efficiency to potentially make your goal at ~50psi, really lbs/min of air will be more important.

You should net an accurate MAP reading with 4.5bar sensor at 50-52psi and a 4bar sensor at 41-44psi. That doesn't mean that you cant boost over that amount, the ECU will just stop changing the reference value for fueling. I've seen cars run 32psi on the stock 2.5bar sensors and be just fine. Running high bar sensors you loose a lot of resolution anyway, so 52psi or 58psi I don't think there will be much fueling compensation in those 6psi... the MAF probably reference 4lbs/min and that will do more to the fueling. So make sure to calibrate your MAF.

Calibrate your sensors and your fuel trims and I think it will be fine.

--Christian

remember the LNF has a volumetric efficiency over the LSJ that extra part of air that make it in because the fuel is injected after the valve closes, I'm not doing the math right now but its like 8% or 11%. Plus with the better fuel control and potential to run more timing, means hotter gasses and higher efficiency. My guess is you will have the efficiency to potentially make your goal at ~50psi, really lbs/min of air will be more important.

You should net an accurate MAP reading with 4.5bar sensor at 50-52psi and a 4bar sensor at 41-44psi. That doesn't mean that you cant boost over that amount, the ECU will just stop changing the reference value for fueling. I've seen cars run 32psi on the stock 2.5bar sensors and be just fine. Running high bar sensors you loose a lot of resolution anyway, so 52psi or 58psi I don't think there will be much fueling compensation in those 6psi... the MAF probably reference 4lbs/min and that will do more to the fueling. So make sure to calibrate your MAF.

Calibrate your sensors and your fuel trims and I think it will be fine.

--Christian

#7

Senior Member

Thread Starter

thanks for the info christian!

I appreciate it!

my only concern is shifting scale doesnt change slope

and by doing so, it will end up giving inaccurate pressure data to the PCM

I don't know, my head is aching right now....

I appreciate it!

my only concern is shifting scale doesnt change slope

and by doing so, it will end up giving inaccurate pressure data to the PCM

I don't know, my head is aching right now....

#8

The real question would end up being if the LNF's E69 ECU relies more on the MAF for its fueling calculations and the ECU would begin interpolating, or if overrunning the MAPs would cause it to start leaning out or not.

What happens when somebody runs stock MAPs and non-GMS1 tune, but runs more boost than the stock sensors can register? Answering this question could provide an answer as far as an option of yours: Running the max MAP sensor you can, but running off of the MAF after that (and perhaps having an analog boost gauge of your own) so you can see what's going on after the MAP maxes out.

What happens when somebody runs stock MAPs and non-GMS1 tune, but runs more boost than the stock sensors can register? Answering this question could provide an answer as far as an option of yours: Running the max MAP sensor you can, but running off of the MAF after that (and perhaps having an analog boost gauge of your own) so you can see what's going on after the MAP maxes out.

#9

Platinum Member

Platinum Member

The max slope for the E69 ECU is 102.4 kpa per 5 volts, but you can shift the scale +-256 kpa.

The stock sensors are 55.68 kpa per 5v, and a -5% offset I think they are 2.5bar

The GMPP sensors are 65.88 kpa per 5v, and a -10% offset they are 3 bar

So your max slope of 102.4 would yield a 4.5 bar sensor with up to a +3% offset.

I would bench calibrate your 5bar sensor, to find its exact scaler and offset. I think you can make it work. May just need a small shift in the scale

Just curious Sky888 why aren't you asking this in the HPTForum?

I've calibrated and tuned for 3.5bar and 4bar sensors and the white paper specifications you get from Bosch aren't ever correct they can be off by 10% or more.

Hit me up by PM here or in the Kappa/Sky/Sol/HPT forums I'd be happy to help you with your project.

--Christian

The stock sensors are 55.68 kpa per 5v, and a -5% offset I think they are 2.5bar

The GMPP sensors are 65.88 kpa per 5v, and a -10% offset they are 3 bar

So your max slope of 102.4 would yield a 4.5 bar sensor with up to a +3% offset.

I would bench calibrate your 5bar sensor, to find its exact scaler and offset. I think you can make it work. May just need a small shift in the scale

Just curious Sky888 why aren't you asking this in the HPTForum?

I've calibrated and tuned for 3.5bar and 4bar sensors and the white paper specifications you get from Bosch aren't ever correct they can be off by 10% or more.

Hit me up by PM here or in the Kappa/Sky/Sol/HPT forums I'd be happy to help you with your project.

--Christian

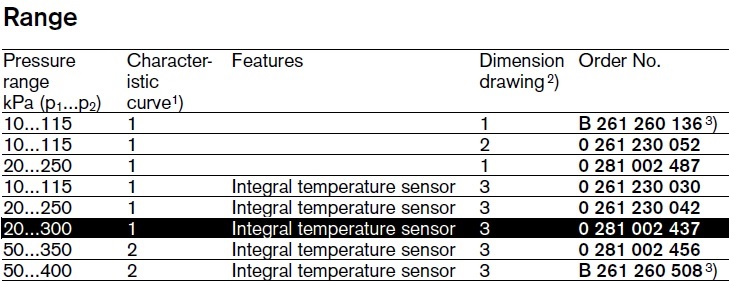

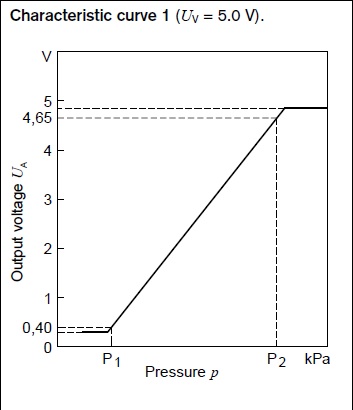

Just in case anyone is curious to the "mystical art" of map sensor scalin, here's a brief 101....

The main information you will need is the sensor data sheet(s) from the manufacturer. This is where you will pull all your info from in order to make your calcs and scaling. Here's an example using Bosch sensors. We'll use the 3 bar sensor specifically because that's what is most commonly used in our cars in the aftermarket.

You will need 4 important bits of info from the data sheets, 1) Minimum sensor pressure 2)Maximum sensor pressure 3)Minimum volts 4)Maximum volts

For Bosch you will see P1 and P2 references used quite a bit.

P1 = minimum sensor pressure value (at a given voltage)

P2 = maximum sensor pressure value (at a given voltage)

So using the data above you can start to apply these numbers are usable values. P1 (20kPa) occurs at 0.4v and P2 (300kPa) at 4.65v (Bosch some how accidently used comma's instead of periods in the voltage axis). Using these values, the slope is 280 (300-20)/ 4.25(4.65-0.4) which works out to 65.88. Multiply 65.88 by five to get the linear value (which is how much range the sensor has over 5v). That will net 329.41.

4.65v would be (65.88*4.65) 306.35kPa with a range of 329.41 at 5v. Subtract 306.35 from 300kPa at 4.65 and you get the -6.35kPa a offset. So as you can see, offsets aren't based off of %'s. They are based off of hard values to accurately show a full voltage to pressure range that ecm can calculate values off of for things like over/under boost conditions.

SKY888, it looks like you're looking to use the AEM sensor I assume (or at least that's the same slope I come up with for the AEM 5 bar)? If so, are you worried about accurate boost pressure readings for fueling or just simply for logging? If it's fueling concerns, I believe Stamina is correct. The ecm uses maf scaling for fueling calcs and not pressure values. You could always start with something like a bosch 4bar, which will easily scale in the E69 ecm, and go from there to at least get some of the tuning bugs worked out too.

#10

Senior Member

Thread Starter

SKY888, it looks like you're looking to use the AEM sensor I assume (or at least that's the same slope I come up with for the AEM 5 bar)? If so, are you worried about accurate boost pressure readings for fueling or just simply for logging? If it's fueling concerns, I believe Stamina is correct. The ecm uses maf scaling for fueling calcs and not pressure values. You could always start with something like a bosch 4bar, which will easily scale in the E69 ecm, and go from there to at least get some of the tuning bugs worked out too.

thanks for the very elaborate post! I get schooled big time with all this extrapolations.

Yes, we were planning to use the AEM 5 bar sensor.

but I guess will get the Bosch 4 bar sensor instead, and work from there.

yeah we would like to get accurate data logging of pressure data

And also for fueling and ignition!

Last edited by SKY888; 12-14-2013 at 06:47 PM.

#11

Senior Member

Thread Starter

Shifting scale doesn't change slope.

And will just keep confusing the ECM by giving inaccurate pressure data?

I don't know, I'm newbie with tuning ESP with hptuners

Thanks

#12

Platinum Member

Platinum Member

I can pretty confidently tell you this though. The primary fueling here is taken care of via the maf and maf correction tables. For example, take someone running the stock 2.5bar map sensors. You can very easily calibrate the ecm to command boost far past the lower map sensors threshold of 23.5psi, yet still completely control fueling in those areas as long as the tuner doesn't lose closed loop control. Further more, even if closed loop control is lost, as long as the maf correction table is scaled nuts on even then you can still hit your commanded fueling when if open loop as long as your axis' are also scaled correctly to the necessary needs of a given setup.

#13

Senior Member

Thread Starter

So you recommend going with a 4 bar sensor first since it's within the ecm's 102.4 kpa/v max?

Fine tune it and work on the bugs even before attempting going with 5 bar sensor?

Fine tune it and work on the bugs even before attempting going with 5 bar sensor?

#14

Platinum Member

Platinum Member

For now it really might not be a bad idea until you can at least source another senor to fit the boost needs you have and the scaling to fit within the ecm's tuning abilities. I'm sure there's got to be something out there that can work though.

#15

Former Vendor

I've posted about this before. The reason LNFs can get away with surpassing the limit of the MAP sensor is simple. We have fuel pressure in the thousands of psi. The ECM uses a calculated cylinder pressure when determining injector flow rate. This cylinder pressure is mainly determined by MAF, RPM, and crank position. Compare this to an LSJ where the injector flow is determined directly by the manifold pressure that it is flowing into. For these reasons, you can't easily tune a 4 bar LSJ on a 3 bar MAP, but you can do this on an LNF without too much difficulty.

Having said that- I can't say that it would matter at all in this case since there is a secondary fuel system that will be providing a significant amount of fuel. Coming up lean on the primary injectors will be a requirement as it is.

This sensor that you have- Why is the scale so large? Using a typical 4.8 volt range, that would make it a 6.2 bar map if the scaling is 129.7 per volt. Does it have a very narrow voltage range?

Having said that- I can't say that it would matter at all in this case since there is a secondary fuel system that will be providing a significant amount of fuel. Coming up lean on the primary injectors will be a requirement as it is.

This sensor that you have- Why is the scale so large? Using a typical 4.8 volt range, that would make it a 6.2 bar map if the scaling is 129.7 per volt. Does it have a very narrow voltage range?

#16

Platinum Member

Platinum Member

The aem 5 bar sensors are a .5 - 4.5 volt sensor with a 515.7kpa total range. So that works out to a 128.93kpa per volt slope. Comparing even a 3.5 bar Bosch sensor to a 3.5 bar aem sensor, the slope on the aem sensor I think was something like 15kpa more per volt than the Bosch if I remember correctly. It's stupid.. Lol

Thread

Thread Starter

Forum

Replies

Last Post