Wtf!!!! anyone with a lc-1

#1

Senior Member

Thread Starter

ok im trying to figure out how to wire up this damn lc-1 to my car.. can someone make sense of this crap?:

2 Mounting and Wiring the LC-1

1. Find a suitable location under your vehicle where the LC-1 body can be mounted. Using

zip ties or other suitable method, fasten the body of the LC-1 device securely to the framerails

or other mounting points as far away from the heat of the exhaust system as the sensor

cable allows. DO NOT zip-tie the LC-1 by the cables.

2. Route the cables from the LC-1 (except sensor cable) into the car interior under the dash.

3. LC-1 Cable connections:

A. Interface and power cables with 6 stripped ends*:

a. Red 12V supply

b. Blue Heater Ground

c. White System Ground

d. Yellow Analog out 1

e. Brown Analog out 2

f. Black Calibration wire

B. Serial In connection, 2.5mm stereo (female) marked as IN

C. Serial Out connection, 2.5 mm stereo (female) marked as OUT.

* 3.1 If you have an LC-1 with only 7 stripped ends the wiring is as follows:

a. Red 12V supply

b. Blue Heater Ground

c. White System Ground

d. Yellow Analog out 1

e. Brown Analog out 2

f. Green Analog Ground

g. Black Calibration wire

4. Connect the RED wire to a switched 12V source in your car. A switched 12V source

goes on as soon as the ignition on the car is on. Make sure the connection is fused with a

minimum fuse size of 5A.

5. The BLUE and WHITE wires should all be grounded to the same ground source.

Optimally, these (and any other MTS device ground) will be soldered to the same lug, and

connected to a single point. When this isn’t possible, connect each one to a separate lug,

and attach in close proximity. Multiple lugs on the same bolt is not optimal, and can result in

unwanted signal “noise.” When possible, soldering is always better than crimping. Please

see chapter 2.3 for more information on Electrical Grounding Concerns.

6. Optionally, the YELLOW (Analog out 1) and/or BROWN (Analog out 2) can be connected

to the analog inputs of other devices such as data loggers, ECUs, or gauges. If either one or

both of these wires are not being used isolate and tape the wire(s) out of the way. The default

analog outputs are as follows: Analog output one is 1.1V = 14 AFR and .1V = 15 AFR. This is

a simulated narrowband signal. Analog output two is setup as 0V = 7.35 AFR and 5V = 22.39

AFR. Note: The LC-1’s heater ground and system ground wires should share the same

grounding location of the analog input’s ground. Refer to chapter 2.2 for recommended

wiring schematics.

7. Optionally connect a momentary push-button switch between ground and the BLACK

calibration wire. Please refer to section 2.1.

Note: The use of the calibration wire is not necessary if the LC-1 is connected to Innovate

Motorsports’ XD-16 digital gauge. If the wire is not are not being used, isolate and tape the

wire out of the way.

I DO NOT UNDERSTAND THIS PART AT ALL:

- 5 -

8. Optionally connect a indication LED (1.2-2.2V, 1-30mA is recommended) between the

calibration wire and ground. Please refer to section 2.1

2.1 Indicator LED and Calibration button hookup:

The LED will communicate the LC-1’s status. To monitor LC-1 status, connect the red wire

(Anode) of the included LED to the calibration wire (black) of the LC-1 and connect the black wire

(Cathode) of the LED to the ground wire of the momentary switch. The grounds to both the

cathode side of the LED and the Push button should be connected with the Heater ground.

a. Note: The included LED will fit the following hole size and panel thickness: a 5/32”

(0.155” - 0.158”) hole size and a panel thickness of 28–16gauge (0.031” - 0.062”).

b. Optionally, any 1.2V - 2.2V (1mA- 30mA) LED may be used. A typical LED has 2

wires called Anode and Cathode. The Cathode side is typically the shorter of the 2

wires or the black wire.

Pressing the push-button or connecting the black wire to ground (a three second press is

required with firmware version 1.10) starts a free air calibration process in the LC-1. MAKE SURE

THE SENSOR IS IN FREE AIR FOR THAT. See chapter 4 for details.

2 Mounting and Wiring the LC-1

1. Find a suitable location under your vehicle where the LC-1 body can be mounted. Using

zip ties or other suitable method, fasten the body of the LC-1 device securely to the framerails

or other mounting points as far away from the heat of the exhaust system as the sensor

cable allows. DO NOT zip-tie the LC-1 by the cables.

2. Route the cables from the LC-1 (except sensor cable) into the car interior under the dash.

3. LC-1 Cable connections:

A. Interface and power cables with 6 stripped ends*:

a. Red 12V supply

b. Blue Heater Ground

c. White System Ground

d. Yellow Analog out 1

e. Brown Analog out 2

f. Black Calibration wire

B. Serial In connection, 2.5mm stereo (female) marked as IN

C. Serial Out connection, 2.5 mm stereo (female) marked as OUT.

* 3.1 If you have an LC-1 with only 7 stripped ends the wiring is as follows:

a. Red 12V supply

b. Blue Heater Ground

c. White System Ground

d. Yellow Analog out 1

e. Brown Analog out 2

f. Green Analog Ground

g. Black Calibration wire

4. Connect the RED wire to a switched 12V source in your car. A switched 12V source

goes on as soon as the ignition on the car is on. Make sure the connection is fused with a

minimum fuse size of 5A.

5. The BLUE and WHITE wires should all be grounded to the same ground source.

Optimally, these (and any other MTS device ground) will be soldered to the same lug, and

connected to a single point. When this isn’t possible, connect each one to a separate lug,

and attach in close proximity. Multiple lugs on the same bolt is not optimal, and can result in

unwanted signal “noise.” When possible, soldering is always better than crimping. Please

see chapter 2.3 for more information on Electrical Grounding Concerns.

6. Optionally, the YELLOW (Analog out 1) and/or BROWN (Analog out 2) can be connected

to the analog inputs of other devices such as data loggers, ECUs, or gauges. If either one or

both of these wires are not being used isolate and tape the wire(s) out of the way. The default

analog outputs are as follows: Analog output one is 1.1V = 14 AFR and .1V = 15 AFR. This is

a simulated narrowband signal. Analog output two is setup as 0V = 7.35 AFR and 5V = 22.39

AFR. Note: The LC-1’s heater ground and system ground wires should share the same

grounding location of the analog input’s ground. Refer to chapter 2.2 for recommended

wiring schematics.

7. Optionally connect a momentary push-button switch between ground and the BLACK

calibration wire. Please refer to section 2.1.

Note: The use of the calibration wire is not necessary if the LC-1 is connected to Innovate

Motorsports’ XD-16 digital gauge. If the wire is not are not being used, isolate and tape the

wire out of the way.

I DO NOT UNDERSTAND THIS PART AT ALL:

- 5 -

8. Optionally connect a indication LED (1.2-2.2V, 1-30mA is recommended) between the

calibration wire and ground. Please refer to section 2.1

2.1 Indicator LED and Calibration button hookup:

The LED will communicate the LC-1’s status. To monitor LC-1 status, connect the red wire

(Anode) of the included LED to the calibration wire (black) of the LC-1 and connect the black wire

(Cathode) of the LED to the ground wire of the momentary switch. The grounds to both the

cathode side of the LED and the Push button should be connected with the Heater ground.

a. Note: The included LED will fit the following hole size and panel thickness: a 5/32”

(0.155” - 0.158”) hole size and a panel thickness of 28–16gauge (0.031” - 0.062”).

b. Optionally, any 1.2V - 2.2V (1mA- 30mA) LED may be used. A typical LED has 2

wires called Anode and Cathode. The Cathode side is typically the shorter of the 2

wires or the black wire.

Pressing the push-button or connecting the black wire to ground (a three second press is

required with firmware version 1.10) starts a free air calibration process in the LC-1. MAKE SURE

THE SENSOR IS IN FREE AIR FOR THAT. See chapter 4 for details.

Last edited by mike25; 07-21-2008 at 09:46 PM.

#2

Senior Member

Join Date: 03-07-05

Location: San Pedro/PV

Posts: 1,733

Likes: 0

Received 0 Likes

on

0 Posts

its not that bad.

power to a power source. make sure its a clean source

ground to a lug. nothing else should be grounded to this same lug.

the led must also be grounded to the SAME PIECE OF METAL the power ground is connected to, but to a different lug.

brown wire = 0-5v analog output (connect to HPT box for logging, i think hole #4 if i remember correctly...ground the HPT box too)

power to a power source. make sure its a clean source

ground to a lug. nothing else should be grounded to this same lug.

the led must also be grounded to the SAME PIECE OF METAL the power ground is connected to, but to a different lug.

brown wire = 0-5v analog output (connect to HPT box for logging, i think hole #4 if i remember correctly...ground the HPT box too)

#3

ok im trying to figure out how to wire up this damn lc-1 to my car.. can someone make sense of this crap?:

2 Mounting and Wiring the LC-1

1. Find a suitable location under your vehicle where the LC-1 body can be mounted. Using

zip ties or other suitable method, fasten the body of the LC-1 device securely to the framerails

2 Mounting and Wiring the LC-1

1. Find a suitable location under your vehicle where the LC-1 body can be mounted. Using

zip ties or other suitable method, fasten the body of the LC-1 device securely to the framerails

2. Route the cables from the LC-1 (except sensor cable) into the car interior under the dash.

3. LC-1 Cable connections:

A. Interface and power cables with 6 stripped ends*:

a. Red 12V supply

b. Blue Heater Ground

c. White System Ground

d. Yellow Analog out 1

e. Brown Analog out 2

f. Black Calibration wire

B. Serial In connection, 2.5mm stereo (female) marked as IN

C. Serial Out connection, 2.5 mm stereo (female) marked as OUT.

* 3.1 If you have an LC-1 with only 7 stripped ends the wiring is as follows:

a. Red 12V supply

b. Blue Heater Ground

c. White System Ground

d. Yellow Analog out 1

e. Brown Analog out 2

f. Green Analog Ground

g. Black Calibration wire

7. Optionally connect a momentary push-button switch between ground and the BLACK

calibration wire. Please refer to section 2.1. Note: The use of the calibration wire is not necessary if the LC-1 is connected to Innovate

Motorsports’ XD-16 digital gauge. If the wire is not are not being used, isolate and tape the

wire out of the way.

I DO NOT UNDERSTAND THIS PART AT ALL:

- 5 -

8. Optionally connect a indication LED (1.2-2.2V, 1-30mA is recommended) between the

calibration wire and ground. Please refer to section 2.1

2.1 Indicator LED and Calibration button hookup:

The LED will communicate the LC-1’s status. To monitor LC-1 status, connect the red wire

(Anode) of the included LED to the calibration wire (black) of the LC-1 and connect the black wire

(Cathode) of the LED to the ground wire of the momentary switch. The grounds to both the

cathode side of the LED and the Push button should be connected with the Heater ground.

a. Note: The included LED will fit the following hole size and panel thickness: a 5/32”

(0.155” - 0.158”) hole size and a panel thickness of 28–16gauge (0.031” - 0.062”).

b. Optionally, any 1.2V - 2.2V (1mA- 30mA) LED may be used. A typical LED has 2

wires called Anode and Cathode. The Cathode side is typically the shorter of the 2

wires or the black wire.

Pressing the push-button or connecting the black wire to ground (a three second press is

required with firmware version 1.10) starts a free air calibration process in the LC-1. MAKE SURE

THE SENSOR IS IN FREE AIR FOR THAT. See chapter 4 for details.

Oh and MAKE SURE THE BATTERY is off during the install. You only learn by doing, this should be a good project, it's pretty straight forward. Use solder for the extensions and terminals if at all possible.

its not that bad.

power to a power source. make sure its a clean source

ground to a lug. nothing else should be grounded to this same lug.

the led must also be grounded to the SAME PIECE OF METAL the power ground is connected to, but to a different lug.

brown wire = 0-5v analog output (connect to HPT box for logging, i think hole #4 if i remember correctly...ground the HPT box too)

power to a power source. make sure its a clean source

ground to a lug. nothing else should be grounded to this same lug.

the led must also be grounded to the SAME PIECE OF METAL the power ground is connected to, but to a different lug.

brown wire = 0-5v analog output (connect to HPT box for logging, i think hole #4 if i remember correctly...ground the HPT box too)

Last edited by theneelster; 07-21-2008 at 10:00 PM. Reason: Automerged Doublepost

#5

Senior Member

Thread Starter

no its not hard at all...this is the part that gets me:

The LED will communicate the LC-1’s status. To monitor LC-1 status, connect the red wire

(Anode) of the included LED to the calibration wire (black) of the LC-1 and connect the black wire

(Cathode) of the LED to the ground wire of the momentary switch. The grounds to both the

cathode side of the LED and the Push button should be connected with the Heater ground.

a. Note: The included LED will fit the following hole size and panel thickness: a 5/32”

(0.155” - 0.158”) hole size and a panel thickness of 28–16gauge (0.031” - 0.062”).

b. Optionally, any 1.2V - 2.2V (1mA- 30mA) LED may be used. A typical LED has 2

wires called Anode and Cathode. The Cathode side is typically the shorter of the 2

wires or the black wire.

Pressing the push-button or connecting the black wire to ground (a three second press is

required with firmware version 1.10) starts a free air calibration process in the LC-1. MAKE SURE

THE SENSOR IS IN FREE AIR FOR THAT. See chapter 4 for details.

is it saying that both the ground(black wire) of the led and the push button need to be hooked up the heater wire, or is it saying that once you connect the push button/led together, that the second wire comming off the push button is the ground and that needs to be hooked to the heater wire?

The LED will communicate the LC-1’s status. To monitor LC-1 status, connect the red wire

(Anode) of the included LED to the calibration wire (black) of the LC-1 and connect the black wire

(Cathode) of the LED to the ground wire of the momentary switch. The grounds to both the

cathode side of the LED and the Push button should be connected with the Heater ground.

a. Note: The included LED will fit the following hole size and panel thickness: a 5/32”

(0.155” - 0.158”) hole size and a panel thickness of 28–16gauge (0.031” - 0.062”).

b. Optionally, any 1.2V - 2.2V (1mA- 30mA) LED may be used. A typical LED has 2

wires called Anode and Cathode. The Cathode side is typically the shorter of the 2

wires or the black wire.

Pressing the push-button or connecting the black wire to ground (a three second press is

required with firmware version 1.10) starts a free air calibration process in the LC-1. MAKE SURE

THE SENSOR IS IN FREE AIR FOR THAT. See chapter 4 for details.

is it saying that both the ground(black wire) of the led and the push button need to be hooked up the heater wire, or is it saying that once you connect the push button/led together, that the second wire comming off the push button is the ground and that needs to be hooked to the heater wire?

#6

Senior Member

Join Date: 05-18-07

Location: New Jersey

Posts: 975

Likes: 0

Received 0 Likes

on

0 Posts

It was a piece of cake, think it through and you will be fine... Make sure you follow the directions on the gauge and connect it to LC-1's brown wire not the yellow wire as shown in the LC-1's instructions... The yellow wire caused my gauge to freak out when I first fired it up... Also make sure you carefully follow the calibration instructions read it, read it a second time, think it through and read it while you are doing it... I spent a total of about three hours installing mine this past weekend.

CA triple gauge A-pillar

Wideband calibration button and led

LC-1 installed under the hood

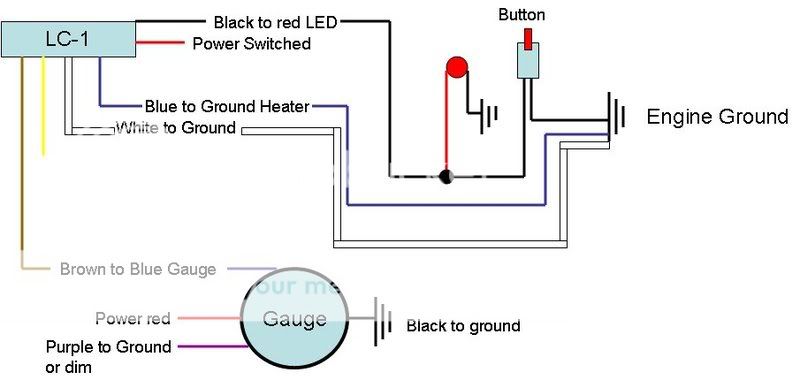

You need to parallel the LED with the switch between the LC-1's black wire and ground with the LED's red wire connected to the LC-1's black wire and the LED's black wire to ground...

CA triple gauge A-pillar

Wideband calibration button and led

LC-1 installed under the hood

no its not hard at all...this is the part that gets me:

The LED will communicate the LC-1’s status. To monitor LC-1 status, connect the red wire

(Anode) of the included LED to the calibration wire (black) of the LC-1 and connect the black wire

(Cathode) of the LED to the ground wire of the momentary switch. The grounds to both the

cathode side of the LED and the Push button should be connected with the Heater ground.

a. Note: The included LED will fit the following hole size and panel thickness: a 5/32”

(0.155” - 0.158”) hole size and a panel thickness of 28–16gauge (0.031” - 0.062”).

b. Optionally, any 1.2V - 2.2V (1mA- 30mA) LED may be used. A typical LED has 2

wires called Anode and Cathode. The Cathode side is typically the shorter of the 2

wires or the black wire.

Pressing the push-button or connecting the black wire to ground (a three second press is

required with firmware version 1.10) starts a free air calibration process in the LC-1. MAKE SURE

THE SENSOR IS IN FREE AIR FOR THAT. See chapter 4 for details.

is it saying that both the ground(black wire) of the led and the push button need to be hooked up the heater wire, or is it saying that once you connect the push button/led together, that the second wire comming off the push button is the ground and that needs to be hooked to the heater wire?

The LED will communicate the LC-1’s status. To monitor LC-1 status, connect the red wire

(Anode) of the included LED to the calibration wire (black) of the LC-1 and connect the black wire

(Cathode) of the LED to the ground wire of the momentary switch. The grounds to both the

cathode side of the LED and the Push button should be connected with the Heater ground.

a. Note: The included LED will fit the following hole size and panel thickness: a 5/32”

(0.155” - 0.158”) hole size and a panel thickness of 28–16gauge (0.031” - 0.062”).

b. Optionally, any 1.2V - 2.2V (1mA- 30mA) LED may be used. A typical LED has 2

wires called Anode and Cathode. The Cathode side is typically the shorter of the 2

wires or the black wire.

Pressing the push-button or connecting the black wire to ground (a three second press is

required with firmware version 1.10) starts a free air calibration process in the LC-1. MAKE SURE

THE SENSOR IS IN FREE AIR FOR THAT. See chapter 4 for details.

is it saying that both the ground(black wire) of the led and the push button need to be hooked up the heater wire, or is it saying that once you connect the push button/led together, that the second wire comming off the push button is the ground and that needs to be hooked to the heater wire?

You need to parallel the LED with the switch between the LC-1's black wire and ground with the LED's red wire connected to the LC-1's black wire and the LED's black wire to ground...

Last edited by BRN169; 07-21-2008 at 10:27 PM. Reason: Automerged Doublepost

#7

Senior Member

Thread Starter

It was a piece of cake, think it through and you will be fine... Make sure you follow the directions on the gauge and connect it to LC-1's brown wire not the yellow wire as shown in the LC-1's instructions... The yellow wire caused my gauge to freak out when I first fired it up... Also make sure you carefully follow the calibration instructions read it, read it a second time, think it through and read it while you are doing it... I spent a total of about three hours installing mine this past weekend.

CA triple gauge A-pillar

Wideband calibration button and led

LC-1 installed under the hood

You need to parallel the LED with the switch between the LC-1's black wire and ground with the LED's red wire connected to the LC-1's black wire and the LED's black wire to ground...

CA triple gauge A-pillar

Wideband calibration button and led

LC-1 installed under the hood

You need to parallel the LED with the switch between the LC-1's black wire and ground with the LED's red wire connected to the LC-1's black wire and the LED's black wire to ground...

lc-1 black wire>led red wire thenled blak wire>left side of push button and then right of push button>blue heater ground

#8

Senior Member

Join Date: 05-18-07

Location: New Jersey

Posts: 975

Likes: 0

Received 0 Likes

on

0 Posts

LC-1's white and blue, LED's black and one side of the switch to ground (same lug if possible)

The LC-1's black wire connects to both one leg of the switch and the red wire from the LED. The LED and the switch are not wired in series they need to be wired in parallel!!!

#10

Senior Member

Thread Starter

no no no...

LC-1's white and blue, LED's black and one side of the switch to ground (same lug if possible)

The LC-1's black wire connects to both one leg of the switch and the red wire from the LED. The LED and the switch are not wired in series they need to be wired in parallel!!!

LC-1's white and blue, LED's black and one side of the switch to ground (same lug if possible)

The LC-1's black wire connects to both one leg of the switch and the red wire from the LED. The LED and the switch are not wired in series they need to be wired in parallel!!!

oh i will...i was the same way when i wired up my boost/oil gauges...

Last edited by mike25; 07-21-2008 at 10:48 PM. Reason: Automerged Doublepost

#13

Senior Member

Join Date: 11-11-05

Location: Oceanside, Ca

Posts: 9,438

Likes: 0

Received 0 Likes

on

0 Posts

#15

Senior Member

Join Date: 05-18-07

Location: New Jersey

Posts: 975

Likes: 0

Received 0 Likes

on

0 Posts

#16

Senior Member

Thread Starter

im not too worried about that...ill just drill the hole to the exact size of the led and put a little bit of glue on from behind

Last edited by mike25; 07-22-2008 at 12:02 AM. Reason: Automerged Doublepost

#17

Senior Member

Thread Starter

i was reading through the guide and it says that the yellow wire is a narrowband hookup and the brown is a 0-5v...question is if the gauge needs the brown wire then how the hell am i suppose to use it to hookup to hpt

#18

Senior Member

Join Date: 03-07-05

Location: San Pedro/PV

Posts: 1,733

Likes: 0

Received 0 Likes

on

0 Posts

i recommend not using the lc-1 as a narrowband + wideband because it's difficult to setup properly. get a new bung welded for the wideband and use it solely as a wideband.

#19

Senior Member

Thread Starter

well i have the bung welded in. im trying to figure out this thing hooks up to hpt....i was told i need a 0-5v output...how can i do this when the gauge needs the 0-5v output as well?

#20

Senior Member

Join Date: 03-07-05

Location: San Pedro/PV

Posts: 1,733

Likes: 0

Received 0 Likes

on

0 Posts

youwould have to loop the connection through the HPT pro box. Basically, the HPT box would have to be permanently mounted in the vehicle somewhere. The HPT box will take the input, and it also has the capability to output simultaneously. Someone correct me if I'm wrong, I never attempted doing it that way.

My AEM shows on the gauge while simultaneously logging on hpt.

My AEM shows on the gauge while simultaneously logging on hpt.

#21

Senior Member

Thread Starter

so basically id have to unhook the 0-5v from the gauge to hook it up to the box?...then again what if i was to splice the wire into two connectors...like add on a piece of the same gauge wire and then branch off of that

#24

Senior Member

Thread Starter

the data logging wire of the lc-1 is the brown wire right? i think i accidentally confused it with the yellow wire...now i have to switch them.

#25

Senior Member

iTrader: (18)

Join Date: 12-20-07

Location: Jeannette, PA

Posts: 3,055

Likes: 0

Received 0 Likes

on

0 Posts

That is correct... The brown wire is 1-5v, the yellow with is only for a narrow band. I just installed my LC-1 with a DB-Red gauge last friday before Dan tuned me. Yea the one analog output is a bitch. When I met Dan and he pulled out his HPT box I was like yea you can use these black headphone jack looking plugs right..? Needless to say I spent the next few minutes pulling apart my A pillar and getting the brown wire off my gauge. Soo yea, if you want to have a wideband gauge and tune at the same time, you will need to split the wire or disconnect it temporarily...