First time ever installing an aftermarket H/U.

#1

Senior Member

Thread Starter

First time ever installing an aftermarket H/U.

So do you guys recommend soldering or crimping the connections?

This is probably the first of many questions. Sorry in advance.

This is probably the first of many questions. Sorry in advance.

#2

Most would recommend soldering; i used heat shrink crimp connections. better be good at either method though and do whatever you're better at.

looks like a ton of wires but if you have a color schematic to follow it's not that bad; rest of the install is fairly straight forward.

looks like a ton of wires but if you have a color schematic to follow it's not that bad; rest of the install is fairly straight forward.

The following users liked this post:

EmperorJJ1 (11-22-2015)

#5

Senior Member

I recommend soldering and using weather tight heat shrink. Its what I do at work.

#8

Senior Member

Couldn't tell you, personally I recommend getting kits from reputable companies and getting a interface module from a company that includes a good warranty. Ive seen a few times the interface fails and causes a plethora of electrical issues.

#10

Senior Member

Thread Starter

Its a pioneer double din I had in another car about 4 years ago. The harness I bought came with the dash kit and it was cheap so if anything i'll just use the dash kit.

#12

Senior Member

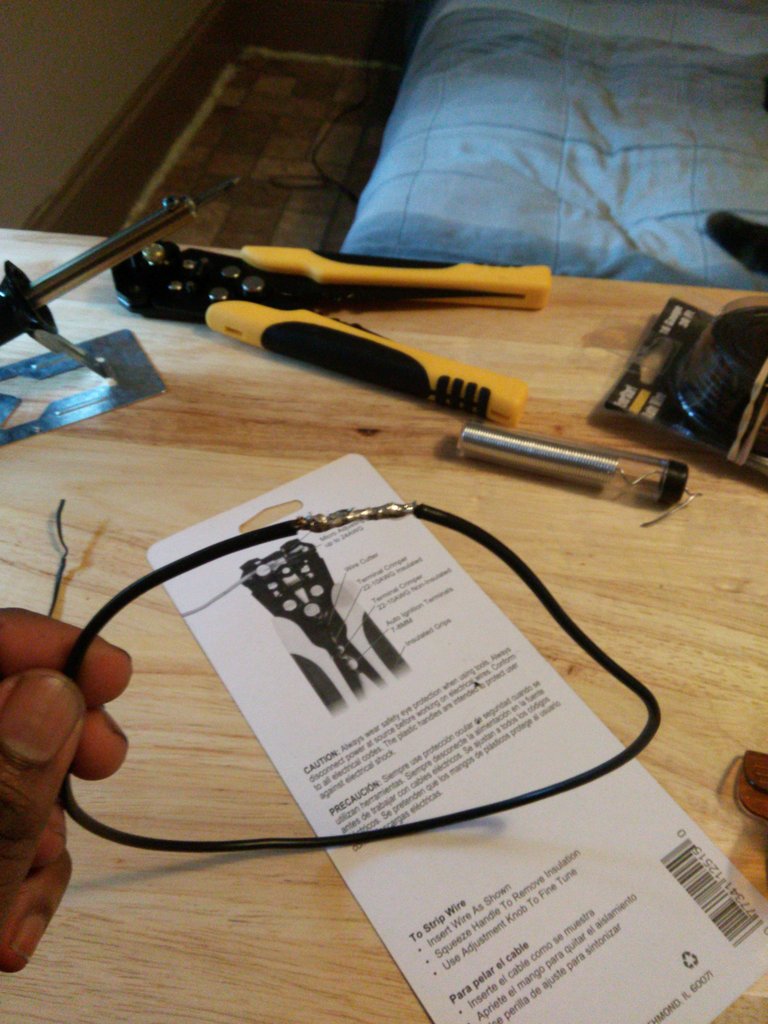

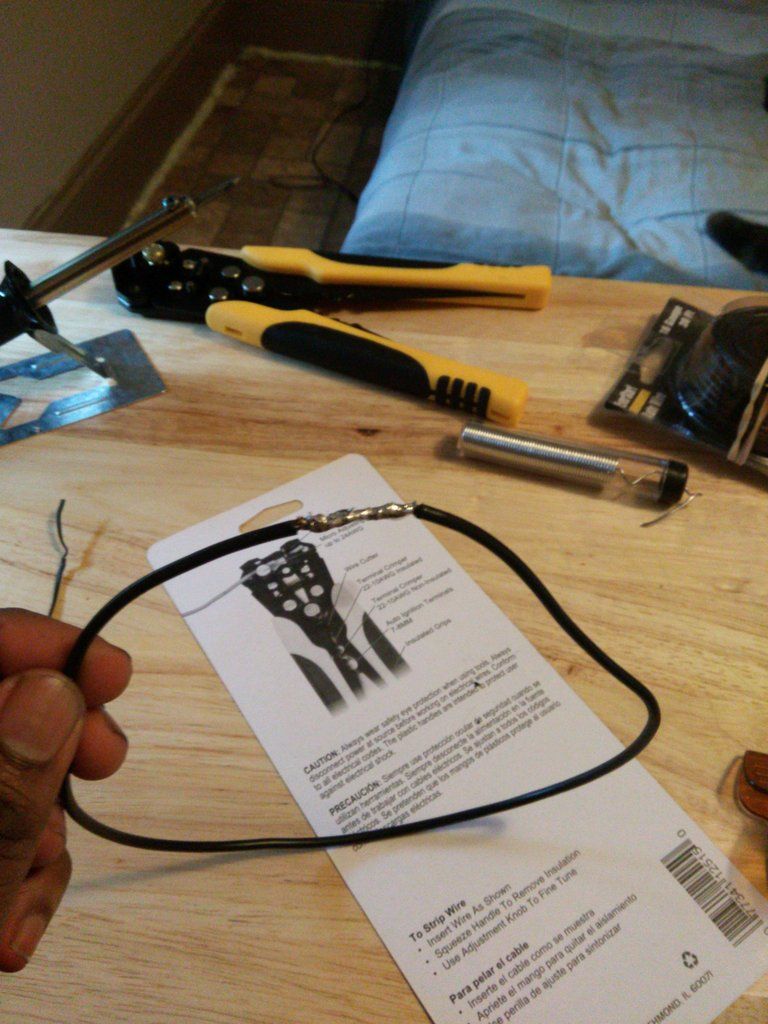

lil messy but not bad. you are letting the two cable ends slide into one another right? kinda meshing the wires. a old school but good test is to try to rip it apart, if it rips the solder its no good, if it rips the wire elsewhere, you got a good solder joint

#14

Senior Member

Thread Starter

First time ever installing an aftermarket H/U.

Yea I mesh the wires then twist. And as for getting it apart, yeah that wasn't happening. I literally tried to rip it apart and it wouldn't separate.

Oh and any tips for getting a cleaner solder joint?

Oh and any tips for getting a cleaner solder joint?

#16

Senior Member

I used to do that as well but I found using a good high heat soldering iron to heat the solder as it flows onto the wire works better. I have trouble getting the wire hot enough without burning the insulation near the end. A good quality rosin core solder goes a long way as well. If I can twist the wires after meshing I do but not too tight, I like a lil free space as it works well to get the

solder to flow into the joint and up the wires.

once I get a good joint I clean it up by using the iron to wick away excess solder, bacically I flick the iron to get it clean (I haven't had good luck with the wet sponge wipe method), touch the joint and get some solder to flow back onto the tip, flick it again and do that a few times and ends up being a nice clean joint. Course I end up with solder spatters all over my floor lol. but that's what concrete is for

solder to flow into the joint and up the wires.

once I get a good joint I clean it up by using the iron to wick away excess solder, bacically I flick the iron to get it clean (I haven't had good luck with the wet sponge wipe method), touch the joint and get some solder to flow back onto the tip, flick it again and do that a few times and ends up being a nice clean joint. Course I end up with solder spatters all over my floor lol. but that's what concrete is for

#18

Senior Member

Yea ive never been to good doing it that way. O/P it would be good to invest in a "Helping Hands". This is what I have a couple of to hold the wires together.

Helping Hands

I like it b/c you can detach the base and pretty much use it anywhere you need to.

Helping Hands

I like it b/c you can detach the base and pretty much use it anywhere you need to.

The following users liked this post:

EmperorJJ1 (11-22-2015)

#22

Senior Member

Thread Starter

Thanks heeter. Yea I figured I'd use more just in case. Plus it was my first try. I just gotta figure out the best way to hold the solder and soldering gun to the wire.

#23

Senior Member

iTrader: (5)

if it doesn't work out you can always use crimp connections. butt connectors are "clean" but crimp caps are a better connection.

Im about 99% sure that i didnt solder the connections for my HU on my old car. With the exception of the ACC and illumination wire i had made myself

Im about 99% sure that i didnt solder the connections for my HU on my old car. With the exception of the ACC and illumination wire i had made myself

Thread

Thread Starter

Forum

Replies

Last Post

breds2k

2.0L LNF Performance Tech

29

10-14-2015 11:56 AM