Forced Induction 101

#1

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

Forced Induction 101

Disclaimer: As with any type of Automotive Upgrade, Forced Induction is full of Grey, it's never as easy as a Black and White answer. There is always an exception to any example. The information presented in this thread is just that, basic information. It is possible to go into much further detail on the subject, which is up to you in the future. When types and styles of forced induction systems are compared it is under the condition that they are all of similar capability. It is always possible to make statements false by taking them out of context or changing the basic parameters of the discussion. When I started to boost cars I would have loved to have had a baseline of information before starting my research. That is why this is here, for you.

No Insult to anyones Knowledge Base, This is More of an introduction to Turbos and Superchargers for thoes who simply do not know. Please feel free to add or correct faults to this thread. It is not perfect nor do I think I am..

Everyone, I mean everyone from a 4 Year old kid to my 80 Year old

Gramma knows that the word "Turbo" has something to do with making

more power. It's a refined system that simply put is a force multiplier.

First, you must understand how an engine makes power before we talk

about "Nitrous" and "Forced Induction" IE. Super Chargers and Turbo Chargers.

This Animation is of a 4 Stroke..

Many of us have seen the T.V. Commercials for Oil where a cut away or

even an animation shows us what can never be seen, the events in the

combustion chamber. Others more qualified on N/A will be able to give a more detailed cycle

including timing of ignition and cams; this is the simple version of all 4

stroke gasoline motors. This is also found in the Mazda Protégé engine.

Suck – The Pistons starting at the top of the cylinder drop creating a

vacuum in the chamber, the intake valves open at the beginning of this

cycle and air and fuel are pulled into the chamber from the intake manifold.

Squeeze – All valves are closed and the piston rises, compressing this

mixture, just past the pistons highest point, (Top Dead Center) or TDC,

the spark is released and the entire mixture goes…

Bang – The explosion or combustion of the air and fuel force down on the

piston, through the rod to the crank, creating rotation that is sent through

the “transmission” (Transmission of Power to the Drive wheels).

Blow – When the combustion is complete and the piston is at its lowest

point, the exhaust valves open and the piston travels up again, this time

forcing the exhaust out of the chamber into the exhaust manifold and out the pipe.

(See Suck for the next step) :

This is the basic 4 Cycles that "OTTO" engine goes through. Each

piston fires in sequence every half revolution to make an even spacing of

firing and thus a well balanced power output.

The engine in its Normally Aspirated state (N/A) as quickly explained

above sucks the air into the chamber. Any restriction in this system will

result in less volume of air being able to make it into the chamber and

thus less fuel being able to combust. Less power. Because more is better,

many of us try to reduce the amount of effort the engine will have to work

to allow for the most air to be delivered and the most exhaust being

removed from the engine. Having said that, Cold air systems and

free flowing exhaust systems do wonders to free up HP. Timing and other

tricks such as porting and polishing the intake and exhaust system allow

for less drag in the system. Eventually you end up at a point where the

engine has reached its limit, simply adding more fuel will not make

more power because there isn’t enough air to complete the explosion

and it goes out. This situation is called “Rich” you will actually loose

power to this. The opposite to this condition is called “Lean” we are

going to talk about this in the next section as it’s the major problem

when dealing with “Forced Induction”.

-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-

No Insult to anyones Knowledge Base, This is More of an introduction to Turbos and Superchargers for thoes who simply do not know. Please feel free to add or correct faults to this thread. It is not perfect nor do I think I am..

Everyone, I mean everyone from a 4 Year old kid to my 80 Year old

Gramma knows that the word "Turbo" has something to do with making

more power. It's a refined system that simply put is a force multiplier.

First, you must understand how an engine makes power before we talk

about "Nitrous" and "Forced Induction" IE. Super Chargers and Turbo Chargers.

This Animation is of a 4 Stroke..

Many of us have seen the T.V. Commercials for Oil where a cut away or

even an animation shows us what can never be seen, the events in the

combustion chamber. Others more qualified on N/A will be able to give a more detailed cycle

including timing of ignition and cams; this is the simple version of all 4

stroke gasoline motors. This is also found in the Mazda Protégé engine.

Suck – The Pistons starting at the top of the cylinder drop creating a

vacuum in the chamber, the intake valves open at the beginning of this

cycle and air and fuel are pulled into the chamber from the intake manifold.

Squeeze – All valves are closed and the piston rises, compressing this

mixture, just past the pistons highest point, (Top Dead Center) or TDC,

the spark is released and the entire mixture goes…

Bang – The explosion or combustion of the air and fuel force down on the

piston, through the rod to the crank, creating rotation that is sent through

the “transmission” (Transmission of Power to the Drive wheels).

Blow – When the combustion is complete and the piston is at its lowest

point, the exhaust valves open and the piston travels up again, this time

forcing the exhaust out of the chamber into the exhaust manifold and out the pipe.

(See Suck for the next step) :

This is the basic 4 Cycles that "OTTO" engine goes through. Each

piston fires in sequence every half revolution to make an even spacing of

firing and thus a well balanced power output.

The engine in its Normally Aspirated state (N/A) as quickly explained

above sucks the air into the chamber. Any restriction in this system will

result in less volume of air being able to make it into the chamber and

thus less fuel being able to combust. Less power. Because more is better,

many of us try to reduce the amount of effort the engine will have to work

to allow for the most air to be delivered and the most exhaust being

removed from the engine. Having said that, Cold air systems and

free flowing exhaust systems do wonders to free up HP. Timing and other

tricks such as porting and polishing the intake and exhaust system allow

for less drag in the system. Eventually you end up at a point where the

engine has reached its limit, simply adding more fuel will not make

more power because there isn’t enough air to complete the explosion

and it goes out. This situation is called “Rich” you will actually loose

power to this. The opposite to this condition is called “Lean” we are

going to talk about this in the next section as it’s the major problem

when dealing with “Forced Induction”.

Last edited by Brian MP5T; 12-11-2006 at 06:39 PM.

#2

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

The simplest explanation of how forced induction works is…

“Forcing more air and fuel into the engine”

Turbo Will Be discussed First. The Supercharger is in the next section.

It makes sense, it’s rather easy to see after knowing how an engine makes power that if you add more air and fuel to the same cylinder, you are able to burn the extra fuel completely and this will result in a larger explosion in the chamber…more force on the piston, more power at the wheels. First I’ll explain how the turbine is built and works. Then I’ll get into how it works for the engine.

Top is a picture of a Garrett T04Z. The Darker side (Iron or Hot Side) is where the exhaust is forced into the “Exhaust Inlet”.

(Square Flange)

After being forced through the "Hot Wheel" or "Turbine Rotor", it leaves out the round hole on the left of the second picture called the exhaust outlet.

This "Hot Wheel" is connected to a second turbine by a shaft supported by the center section of the turbo called the bearing housing.

This second turbine is housed in the lighter colour side (Aluminium or Cold Side)

It is where the air is taken and pumped at very high speed by the compressor wheel out the compressor outlet.

The turbine is required to spin very fast to pump, in the range of 50,000 RPM to 125,000 RPM.

(125,000 should be considered the point of failure or breakdown)

This shaft must be fed by oil from the engine at all time from a dedicated line from the lubrication system. Filtered oil is sent through the bearing housing and passes around and on the journal or ball bearing. This oil is subjected to massive heat and pressure resulting it the oil being transformed into a milky puss, the better the oil, the better it will stand up to this before breaking down. The oil returns to the lubrication system where it is filtered and pumped again. Most modern bearing housing are also liquid cooled to reduce the heat of the entire area prolonging oil and bearing life.

The Picture of the Bearing Cross section is the Attachment...

The Turbo is like a human heart. All the ports in it have to be hooked up for it to work. This is why it takes alot of time to build a kit from scratch or even bolt up a kit. You can't just install the manifold and wait till next weekend to do the rest.

The fact that a turbo is driven by exhaust gasses and not tied to the motor is it’s biggest plus. If designed well, a turbo will spool low on the power band and hold max boost all the way through the rev range. A short shift and a well set Blow-off valve will have you back at max boost as soon as you are in the next gear. The result is the engine is receiving full boost for the entire sweep unlike the supercharger that makes peak boost only just shy of redline. If Boost = HP gains, you quickly see how desirable this is. The second Pro for a turbo is that the energy used to turn it is simply a waste product from the internal combustion of the engine. If the turbo adds 100 HP to the engine, on paper you are getting 99 HP at the wheels. The loss is due to the backpressure that is imposed on the engine which can be a factor if the turbo is too small. The process of internal combustion is not perfectly efficient. If it were, all the energy released by the fuel would go directly to turning the crank, but there is heat and frictional loss. There is a lot of loss due to heat, some ends up in the block and is taken away by the coolant. The rest travels out the exhaust valves and expands into the exhaust manifold. This expanding gas spools the turbo as it leaves the car. A turbo reclaims some of that wasted energy to make the car more powerful. It is a real slick refined system.

“Forcing more air and fuel into the engine”

Turbo Will Be discussed First. The Supercharger is in the next section.

It makes sense, it’s rather easy to see after knowing how an engine makes power that if you add more air and fuel to the same cylinder, you are able to burn the extra fuel completely and this will result in a larger explosion in the chamber…more force on the piston, more power at the wheels. First I’ll explain how the turbine is built and works. Then I’ll get into how it works for the engine.

Top is a picture of a Garrett T04Z. The Darker side (Iron or Hot Side) is where the exhaust is forced into the “Exhaust Inlet”.

(Square Flange)

After being forced through the "Hot Wheel" or "Turbine Rotor", it leaves out the round hole on the left of the second picture called the exhaust outlet.

This "Hot Wheel" is connected to a second turbine by a shaft supported by the center section of the turbo called the bearing housing.

This second turbine is housed in the lighter colour side (Aluminium or Cold Side)

It is where the air is taken and pumped at very high speed by the compressor wheel out the compressor outlet.

The turbine is required to spin very fast to pump, in the range of 50,000 RPM to 125,000 RPM.

(125,000 should be considered the point of failure or breakdown)

This shaft must be fed by oil from the engine at all time from a dedicated line from the lubrication system. Filtered oil is sent through the bearing housing and passes around and on the journal or ball bearing. This oil is subjected to massive heat and pressure resulting it the oil being transformed into a milky puss, the better the oil, the better it will stand up to this before breaking down. The oil returns to the lubrication system where it is filtered and pumped again. Most modern bearing housing are also liquid cooled to reduce the heat of the entire area prolonging oil and bearing life.

The Picture of the Bearing Cross section is the Attachment...

The Turbo is like a human heart. All the ports in it have to be hooked up for it to work. This is why it takes alot of time to build a kit from scratch or even bolt up a kit. You can't just install the manifold and wait till next weekend to do the rest.

The fact that a turbo is driven by exhaust gasses and not tied to the motor is it’s biggest plus. If designed well, a turbo will spool low on the power band and hold max boost all the way through the rev range. A short shift and a well set Blow-off valve will have you back at max boost as soon as you are in the next gear. The result is the engine is receiving full boost for the entire sweep unlike the supercharger that makes peak boost only just shy of redline. If Boost = HP gains, you quickly see how desirable this is. The second Pro for a turbo is that the energy used to turn it is simply a waste product from the internal combustion of the engine. If the turbo adds 100 HP to the engine, on paper you are getting 99 HP at the wheels. The loss is due to the backpressure that is imposed on the engine which can be a factor if the turbo is too small. The process of internal combustion is not perfectly efficient. If it were, all the energy released by the fuel would go directly to turning the crank, but there is heat and frictional loss. There is a lot of loss due to heat, some ends up in the block and is taken away by the coolant. The rest travels out the exhaust valves and expands into the exhaust manifold. This expanding gas spools the turbo as it leaves the car. A turbo reclaims some of that wasted energy to make the car more powerful. It is a real slick refined system.

#3

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

Here is a Supercharger on a Mazda Miata. What a Supercharger does is

very similar to a Turbo, however, how that air is forced is very diferent.

Each has it drawbacks and advantages.

The supercharger is often much easier to install, there are fewer problems because the system has nothing to do with the exhaust, there is no problem with boost control because it’s as simple as changing to a larger or smaller drive pulley. However, a supercharger is driven by the belts and for it to function; it robs the engine of power just like power steering or an alternator. Luckily the Supercharger usually makes a lot more power than what is required to drive it. If the engine makes 100 more Hp and it only takes 30 Hp to drive the supercharger, the engine is 70 Hp Stronger. This is why many chose turbo over Supercharger and is it's only real negative.

You still have to build the engine to handle the total boost but get a bit less HP than the turbo running at the same boost due to the driveline loss.

The supercharger comes in several forms and sizes just like a turbo.

Some setups look like a turbo and even allow the use of an Intercooler to increase performance and reliability.

Most are bolted directly to the intake manifold or even replace the entire intake manifold.

The Supercharger is instant power and is creating boost all the time. However because it's linked directly to the RPM of the engine by a belt, the amount of boost it adds is directly related to the speed of the engine. So at 3000 RPM you would get 5 PSI of boost, At 6000 RPM you would get 10 Psi.

Superchargers are much more popular with Mustangs, American Muscle Cars and other large displacement cars.

very similar to a Turbo, however, how that air is forced is very diferent.

Each has it drawbacks and advantages.

The supercharger is often much easier to install, there are fewer problems because the system has nothing to do with the exhaust, there is no problem with boost control because it’s as simple as changing to a larger or smaller drive pulley. However, a supercharger is driven by the belts and for it to function; it robs the engine of power just like power steering or an alternator. Luckily the Supercharger usually makes a lot more power than what is required to drive it. If the engine makes 100 more Hp and it only takes 30 Hp to drive the supercharger, the engine is 70 Hp Stronger. This is why many chose turbo over Supercharger and is it's only real negative.

You still have to build the engine to handle the total boost but get a bit less HP than the turbo running at the same boost due to the driveline loss.

The supercharger comes in several forms and sizes just like a turbo.

Some setups look like a turbo and even allow the use of an Intercooler to increase performance and reliability.

Most are bolted directly to the intake manifold or even replace the entire intake manifold.

The Supercharger is instant power and is creating boost all the time. However because it's linked directly to the RPM of the engine by a belt, the amount of boost it adds is directly related to the speed of the engine. So at 3000 RPM you would get 5 PSI of boost, At 6000 RPM you would get 10 Psi.

Superchargers are much more popular with Mustangs, American Muscle Cars and other large displacement cars.

#4

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

The Turbo has a problem known as "TURBO LAG", Lag is the time it takes from when you try to accelerate to when the turbo has spooled up to create the pressure required by the engine. On a car with a very large turbo for the size of engine, this lag can be a very big negative in the cars performance. The Turbo will only be able to make boost at the upper range of the power band because of the amount of exaust gas required to spool it. A Turbo that is smaller will spool much faster and much lower on the power band, but it will have to spin much faster to make the same boost as the larger turbo. So there must be a balance between Lag and Boost. The requirements of the engine must be taken into account when selecting the Turbo for the application. Most turbo kits are very well thought out and are complete; however, if the kit is only designed to run at 6 Psi, the entire kit may be completely inadequate for 10 Psi. Choose the turbo wisely; it is one of the most important design choices that will change how your car performs.

#6

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

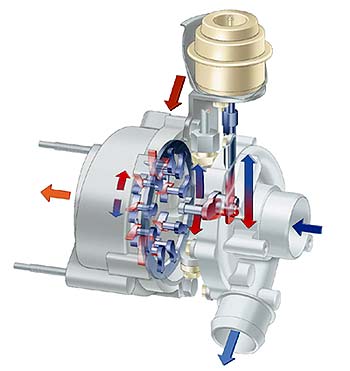

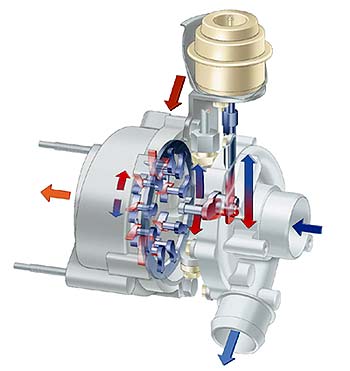

Variable Vane is not commonly used. It allows for a fast spool and then high pressure. Best of both worlds with only "Complication and Expense" as it's major drawbacks.

EDIT: UPDATED

Porsche Has Recently Introduced it in the 911 Turbo. Twin Computer Controled Variable. It kills lag and will give you power in an instant.

Ok FORGET This Old ****...PORSCHE Fixing the Automotive World One Part At A Time.

They have refined it to the point that there is no lag at all. The Car behaves like a Big N/A monster with a near linear torque curve.

Variable Closed

.jpg)

Variable Open

.jpg)

EDIT: UPDATED

Porsche Has Recently Introduced it in the 911 Turbo. Twin Computer Controled Variable. It kills lag and will give you power in an instant.

Ok FORGET This Old ****...PORSCHE Fixing the Automotive World One Part At A Time.

They have refined it to the point that there is no lag at all. The Car behaves like a Big N/A monster with a near linear torque curve.

Variable Closed

.jpg)

Variable Open

.jpg)

Last edited by Brian MP5T; 11-06-2006 at 05:25 AM.

#7

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

By Definition a Turbo is a Supercharger yes, but it isn't because of the way it operates. So it's just simply known as a Turbocharger because it is a pair of turbines connected by a shaft.

The noun supercharger has one meaning:

Meaning #1: compressor that forces increased oxygen into the cylinders of an internal-combustion engine

"Superchargers"

A Centerfugal Supercharger combines the negaitve qualities of both a Turbo and a Supercharger. They are the least capable at making good boost pressure low but are effecient at low pressure applications unless driven a very high speed. They make heat like a turbo but Rob Horsepower like a supercharger. So that makes them...Moderately desireable for big horsepower when compared. More for minor power adding.

A Gearbox (Pro Charger) will increase the speed of the S/C to more useable levels but care and planning is required to not overboost near the redline.

------------------------------------------------------------------------------

From.. http://en.wikipedia.org/wiki/Centrifugal_supercharger

The centrifugal type supercharger is practically identical in operation to a turbocharger, with the exception that instead of exhaust gases driving an impeller, there is only a compressor housing, and that is driven from the crankshaft via a drive belt. As such the centrifugal exhibits the same benefits and down-sides. Boost increases with the square of RPM (unlike the linear nature of the positive displacement devices), however low-rpm boost suffers due to the fact that air can pass back through the supercharger with little restriction until RPMs rise sufficiently to counteract the effect. Of all the belt-driven supercharger types this type exhibits the highest efficiency, and due to its design and lack of low-down boost is often employed on near standard compression engines. The Roots type supercharger and the twin-screw type supercharger, however, produce low-rpm boost and as such feel far more reactive on the road.

That's alot of air..

The Prochargers you see here are still centrifugal Superchargers but use a gearbox to overcome the natural design difficulty with having to spin fast enough to build useable boost down low. This will raise the amount of drag on the belt, but balance off the power curve with gearing. They have made some of the most powerfull cars in the world with brute force.

The noun supercharger has one meaning:

Meaning #1: compressor that forces increased oxygen into the cylinders of an internal-combustion engine

"Superchargers"

A Centerfugal Supercharger combines the negaitve qualities of both a Turbo and a Supercharger. They are the least capable at making good boost pressure low but are effecient at low pressure applications unless driven a very high speed. They make heat like a turbo but Rob Horsepower like a supercharger. So that makes them...Moderately desireable for big horsepower when compared. More for minor power adding.

A Gearbox (Pro Charger) will increase the speed of the S/C to more useable levels but care and planning is required to not overboost near the redline.

------------------------------------------------------------------------------

From.. http://en.wikipedia.org/wiki/Centrifugal_supercharger

The centrifugal type supercharger is practically identical in operation to a turbocharger, with the exception that instead of exhaust gases driving an impeller, there is only a compressor housing, and that is driven from the crankshaft via a drive belt. As such the centrifugal exhibits the same benefits and down-sides. Boost increases with the square of RPM (unlike the linear nature of the positive displacement devices), however low-rpm boost suffers due to the fact that air can pass back through the supercharger with little restriction until RPMs rise sufficiently to counteract the effect. Of all the belt-driven supercharger types this type exhibits the highest efficiency, and due to its design and lack of low-down boost is often employed on near standard compression engines. The Roots type supercharger and the twin-screw type supercharger, however, produce low-rpm boost and as such feel far more reactive on the road.

That's alot of air..

The Prochargers you see here are still centrifugal Superchargers but use a gearbox to overcome the natural design difficulty with having to spin fast enough to build useable boost down low. This will raise the amount of drag on the belt, but balance off the power curve with gearing. They have made some of the most powerfull cars in the world with brute force.

#8

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

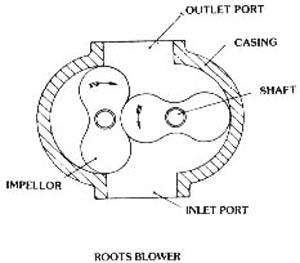

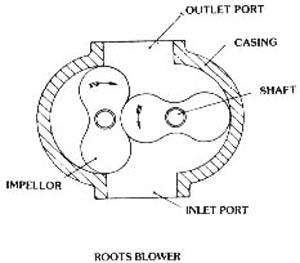

"Roots Supercharger"

Known more commonly as a Blower, Should be considered "Old Tech".

Used in Two Stroke Diesel Engines and many classic Hot rods that are true to their roots.

A large and relitively ineffecient type of supercharger (By Todays Technology). Normally a pair of "Gears" mesh at moderate speed to create positive pressure on the outlet side of the charger. This "Blower" is normalkly bolted directly to the intake manifold, makes very litttle heat in the process of creating boost and has no requirement for an intercooler.

------------------------------------------------------------------------------

From: http://en.wikipedia.org/wiki/Roots_type_supercharger

The Roots type supercharger or Roots blower is a positive displacement type device that operates by pulling air through a pair of meshing lobes not dissimilar to a set of stretched gears. Air is trapped in pockets between the lobes and carried between the intake side to the exhaust. The supercharger is typically driven directly from the engine's crankshaft via a belt. In order for most typical Roots superchargers to deliver air at greater pressure than atmospheric, they should be geared so that they turns faster than the engine. It is named for the brothers Philander and Francis Roots, who first patented the basic design in 1860 as an air pump for use in blast furnaces and other industrial applications. In 1900, Gottlieb Daimler included a Roots-style supercharger in a patented engine design, making the Roots-type supercharger the oldest of the various designs now available.

Out of the three basic supercharger types the Roots is considered the least efficient. However, it is simple and widely used and thus is invariably the most cost efficient. It is also more effective than alternative superchargers at developing compression at low engine rpms, making it a popular choice for passenger automobile applications. Peak boost can be achieved by about 2000 rpm. Much work has been done to improve the efficiency of the Roots type supercharger, but because it does not have internal compression (the design can be classified as just a "blower") it will never have the same potential as the twin-screw type supercharger, or the centrifugal type supercharger.

All supercharger types benefit from the use of an intercooler to remove heat produced during compression.

The Roots design is commonly used on two-stroke diesel engines, which require some form of forced induction since there is no intake stroke. In this application, the blower does not often

provide significant compression and these engines are considered naturally aspirated; turbochargers are generally used when significant boost is needed.

Known more commonly as a Blower, Should be considered "Old Tech".

Used in Two Stroke Diesel Engines and many classic Hot rods that are true to their roots.

A large and relitively ineffecient type of supercharger (By Todays Technology). Normally a pair of "Gears" mesh at moderate speed to create positive pressure on the outlet side of the charger. This "Blower" is normalkly bolted directly to the intake manifold, makes very litttle heat in the process of creating boost and has no requirement for an intercooler.

------------------------------------------------------------------------------

From: http://en.wikipedia.org/wiki/Roots_type_supercharger

The Roots type supercharger or Roots blower is a positive displacement type device that operates by pulling air through a pair of meshing lobes not dissimilar to a set of stretched gears. Air is trapped in pockets between the lobes and carried between the intake side to the exhaust. The supercharger is typically driven directly from the engine's crankshaft via a belt. In order for most typical Roots superchargers to deliver air at greater pressure than atmospheric, they should be geared so that they turns faster than the engine. It is named for the brothers Philander and Francis Roots, who first patented the basic design in 1860 as an air pump for use in blast furnaces and other industrial applications. In 1900, Gottlieb Daimler included a Roots-style supercharger in a patented engine design, making the Roots-type supercharger the oldest of the various designs now available.

Out of the three basic supercharger types the Roots is considered the least efficient. However, it is simple and widely used and thus is invariably the most cost efficient. It is also more effective than alternative superchargers at developing compression at low engine rpms, making it a popular choice for passenger automobile applications. Peak boost can be achieved by about 2000 rpm. Much work has been done to improve the efficiency of the Roots type supercharger, but because it does not have internal compression (the design can be classified as just a "blower") it will never have the same potential as the twin-screw type supercharger, or the centrifugal type supercharger.

All supercharger types benefit from the use of an intercooler to remove heat produced during compression.

The Roots design is commonly used on two-stroke diesel engines, which require some form of forced induction since there is no intake stroke. In this application, the blower does not often

provide significant compression and these engines are considered naturally aspirated; turbochargers are generally used when significant boost is needed.

#9

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

Now we are talking modern.

An Old design that has been refined that is broken down into two basic types.

Eaton Supercharger

"Twin Opposed Counter Rotating Screws"

Like in the Cobalt SS

The screws are kept in time by a drive line. A set of gears normally suspended in oil or fed directly from the block. Being fed from the block will keep the temperature more stable as the oil is constantly being cycled and filtered through the engine.

There is normally a large belt attached to the crank that drives the supercharger. The top Cover or scoop sometimes used just helps along.

Lysholm Supercharger

"Counter Rotating Male and Female Screws"

The Lysholm supercharger looks similar to a helical Roots blower, but with rotors that are far more twisted, and have a conical taper. The result is that these "screw-type" compressors have an internal compression ratio, making them more efficient in high-boot applications. A Lysholm compressor will continue to compress air as long as it is being turned, even if a bypass valve allows that air to be recerculated. The only way to eliminate a Lysholm compressor's parasitic drag at cruise is to let it stop turning via a clutch. This makes it rather difficult to justify in a economy designed car. This should be only considered when high boost pressures with minimal heat and maximum power are needed. This style of Supercharger has a characteristic "Scream" under load.

Just on a side not this is the style I have selected for my 944 Project as I want High Boost with no heat and do not care about fuel consumption under load.

An Old design that has been refined that is broken down into two basic types.

Eaton Supercharger & Lysholm Supercharger

Eaton Supercharger

"Twin Opposed Counter Rotating Screws"

Like in the Cobalt SS

The screws are kept in time by a drive line. A set of gears normally suspended in oil or fed directly from the block. Being fed from the block will keep the temperature more stable as the oil is constantly being cycled and filtered through the engine.

There is normally a large belt attached to the crank that drives the supercharger. The top Cover or scoop sometimes used just helps along.

Lysholm Supercharger

"Counter Rotating Male and Female Screws"

The Lysholm supercharger looks similar to a helical Roots blower, but with rotors that are far more twisted, and have a conical taper. The result is that these "screw-type" compressors have an internal compression ratio, making them more efficient in high-boot applications. A Lysholm compressor will continue to compress air as long as it is being turned, even if a bypass valve allows that air to be recerculated. The only way to eliminate a Lysholm compressor's parasitic drag at cruise is to let it stop turning via a clutch. This makes it rather difficult to justify in a economy designed car. This should be only considered when high boost pressures with minimal heat and maximum power are needed. This style of Supercharger has a characteristic "Scream" under load.

Just on a side not this is the style I have selected for my 944 Project as I want High Boost with no heat and do not care about fuel consumption under load.

Last edited by Brian MP5T; 12-12-2006 at 05:07 AM.

#10

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

Detonation and Pre-Ignition will destroy a motor in seconds. It is very important to remember and to understand when changing Turbo components and increasing boost pressure. I would have writen it myself, but this is a very complete description.

Taken From Wixpidia..

Detonation

The fuel/air mixture is normally ignited slightly before the point of maximum compression to allow a small time for the flame-front of the burning fuel to expand throughout the mixture, so that maximum pressure occurs at the optimum point. The flame-front moves at roughly 110 feet/second during normal combustion. It is only when the remaining unburned mixture is heated and pressurized by the advancing flame front for a certain length of time that the knocking effect occurs. It is caused by an instantaneous ignition of the remaining fuel/air mixture in the form of an explosion. The cylinder pressure rises dramatically beyond design limits. If allowed to persist detonation will cause vibration and damage to engine parts.

Pre-ignition

Detonation, explained above, is a different phenomenon from pre-ignition, which occurs when the air/fuel mixture in the cylinder (or even just entering the cylinder) ignites before the spark plug fires. Pre-ignition is accompanied by a loud hacking noise and caused by an ignition source other than the spark. Heat can buildup in engine intake or cylinder components due to improper design e.g. spark plugs with too low a heat rating or due to maintenance, e.g. carbon deposits in the combustion chamber, or also due to overheating of the air/fuel mixture during compression. This heat buildup can only be prevented by eliminating the overheating (through redesign or cleaning) or the compression effects (by reducing the load on the engine or temperature of intake air). As such, if pre-ignition is allowed to continue for any length of time, power output reduces drastically and engine damage can result.

Pre-ignition may lead to detonation and detonation may lead to pre-ignition or either may exist separately.

Taken From Wixpidia..

Detonation

The fuel/air mixture is normally ignited slightly before the point of maximum compression to allow a small time for the flame-front of the burning fuel to expand throughout the mixture, so that maximum pressure occurs at the optimum point. The flame-front moves at roughly 110 feet/second during normal combustion. It is only when the remaining unburned mixture is heated and pressurized by the advancing flame front for a certain length of time that the knocking effect occurs. It is caused by an instantaneous ignition of the remaining fuel/air mixture in the form of an explosion. The cylinder pressure rises dramatically beyond design limits. If allowed to persist detonation will cause vibration and damage to engine parts.

Pre-ignition

Detonation, explained above, is a different phenomenon from pre-ignition, which occurs when the air/fuel mixture in the cylinder (or even just entering the cylinder) ignites before the spark plug fires. Pre-ignition is accompanied by a loud hacking noise and caused by an ignition source other than the spark. Heat can buildup in engine intake or cylinder components due to improper design e.g. spark plugs with too low a heat rating or due to maintenance, e.g. carbon deposits in the combustion chamber, or also due to overheating of the air/fuel mixture during compression. This heat buildup can only be prevented by eliminating the overheating (through redesign or cleaning) or the compression effects (by reducing the load on the engine or temperature of intake air). As such, if pre-ignition is allowed to continue for any length of time, power output reduces drastically and engine damage can result.

Pre-ignition may lead to detonation and detonation may lead to pre-ignition or either may exist separately.

#11

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

Compression Ratio

Taken from Wikipedia.

The Compression ratio is a single number that can be used to predict the performance of any internal-combustion engine. It is a ratio between the volume of a combustion chamber when the piston is at the bottom of its stroke, and the volume when the piston is at the top of its stroke. The higher the compression ratio, the more mechanical energy an engine can squeeze from its air-fuel mixture. Higher compression ratios, however, also make detonation more likely.

So based on this if you had three identical 2.0L motors all with different compression ratios, 8:1, 9:1, 10:1. They would all make different power. The 10:1 would be the most powerful but it would also be more prone to detonation. You could plan for and reduce the chance of detonation by changing the fuel, intake temperature, colder spark plugs, retarding timing etc...

The compression ratio is based on atmospheric pressure. Now when you pressurize the intake, the compression ratio does not change, but because there is more air in the cylinder to start with, you have effectively increased the compression ratio. The end result is air and fuel being compressed to a much higher pressure than before. This in itself makes more horsepower because there is more air and fuel to burn, but also, the compression in the piston is higher as well. It's wonderful; you get more power from two factors. The increase in pressure has brought the motor much closer to the detonation threshold. The Higher the boost, the more likely is to detonate. So just as before, changing the fuel, intake temperature, colder spark plugs, retarding timing are all factors. You can sacrifice in the design stage of a motor the base compression ratio for the ability to run a higher boost with the same safety margin in regards to detonation. You will loose off boost performance at low RPM compared to a Higher compression, however, as soon as that higher boost kicks in, you will never miss the lower end. This is a factor with turbos and lag.

The Porsche 944 has a compression ratio of 10:1

The Porsche 944 Turbo has a compression ratio of 8:1

These Engines in their stock form have been designed with the end result in mind. Porsche has selected a HP goal for both, the turbo and boost pressure are designed to work with the timing compression ratio and intercooler.

You can over boost a turbo car a bit without much danger, too much boost without proper supporting mods and you will end up with a burnt piston or a split rod.

Remember to factor in the "Goal" and "Result" in any project.

Here is a High Compression Piston good for N/A Applications..

Low Compression More suited for Forced induction.

Taken from Wikipedia.

The Compression ratio is a single number that can be used to predict the performance of any internal-combustion engine. It is a ratio between the volume of a combustion chamber when the piston is at the bottom of its stroke, and the volume when the piston is at the top of its stroke. The higher the compression ratio, the more mechanical energy an engine can squeeze from its air-fuel mixture. Higher compression ratios, however, also make detonation more likely.

So based on this if you had three identical 2.0L motors all with different compression ratios, 8:1, 9:1, 10:1. They would all make different power. The 10:1 would be the most powerful but it would also be more prone to detonation. You could plan for and reduce the chance of detonation by changing the fuel, intake temperature, colder spark plugs, retarding timing etc...

The compression ratio is based on atmospheric pressure. Now when you pressurize the intake, the compression ratio does not change, but because there is more air in the cylinder to start with, you have effectively increased the compression ratio. The end result is air and fuel being compressed to a much higher pressure than before. This in itself makes more horsepower because there is more air and fuel to burn, but also, the compression in the piston is higher as well. It's wonderful; you get more power from two factors. The increase in pressure has brought the motor much closer to the detonation threshold. The Higher the boost, the more likely is to detonate. So just as before, changing the fuel, intake temperature, colder spark plugs, retarding timing are all factors. You can sacrifice in the design stage of a motor the base compression ratio for the ability to run a higher boost with the same safety margin in regards to detonation. You will loose off boost performance at low RPM compared to a Higher compression, however, as soon as that higher boost kicks in, you will never miss the lower end. This is a factor with turbos and lag.

The Porsche 944 has a compression ratio of 10:1

The Porsche 944 Turbo has a compression ratio of 8:1

These Engines in their stock form have been designed with the end result in mind. Porsche has selected a HP goal for both, the turbo and boost pressure are designed to work with the timing compression ratio and intercooler.

You can over boost a turbo car a bit without much danger, too much boost without proper supporting mods and you will end up with a burnt piston or a split rod.

Remember to factor in the "Goal" and "Result" in any project.

Here is a High Compression Piston good for N/A Applications..

Low Compression More suited for Forced induction.

#12

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

Intercooler

The Front Mount Intercooler or FMIC is normally the first thing in the car. It normally sits before the radiator as seen here...

Alright, You want to Up the Boost and Up The HP, You have to think first. Every time you change something in a car to get performance, there are other things that will change as well, some (Most) of them are negative.

Oxygen is the only hard thing to put in an Engine...

More Fuel, No Problem,

Bigger Spark, No Problem.

Agreed. So Back to Chemistry.

Air is a mixture of Nitrogen and Oxygen. The Hotter a Gas is (In this case air) The fewer the number of atoms are present in that volume.

So

1 Ft/Cu of air at 100Deg will have many less molecules than. 1 Ft/Cu of air at Zero Deg.

Just by changing the temperature of the intake, you have made more HP because you have more Oxygen, so you can burn more Fuel.

Easy Fundamental Concept #1.

A Turbo and Supercharger both compress air. The action of compressing the air makes the air much hotter. The amount of heat depends on how efficient the compressor is but it can be calculated. The More pressure the compressor is making the hotter the air becomes.

Easy Fundamental Concept #2.

You want more boost, you get more heat. More heat equals less molecules per volume of air. So as you are compressing more air into the engine, you are not getting the same density of air and are not getting as much oxygen as you should for the volume.

The intercooler is designed to remove the heat caused by compression.

This reduces the negative effect of compressing air and Makes More Horsepower.

Reduces The Likeliness of Detonation.

Pressure Drop

Basically the loss or restriction that an intercooler has.

EG#1. To get 10.0 Psi at the engine after the intercooler the turbo has to push 11.0 Psi before.

That is an acceptable drop.

EG#2. To get 10 Psi at the engine after the Less Efficient intercooler the turbo has to push 13.0 Psi before.

That is not helping. To get the turbo to make the extra 3 Psi, it will be creating allot more heat than EG#1. So this intercooler is not capable for the Volume that is required to move with efficiency. It will eventually heat soak and the intake will start to heat up. OMG! The extra 3 Psi will cancel out with heat. Minimal Gains.

The Intercooler must be capable to move the volume of air with as little pressure loss as possible.

Heat Soak

Heat soak is simply when the intercooler is overwhelmed with constant high heat that it is not capable of dissipating. The longer the turbo makes boost, the hotter the intercooler will get hotter to the point where the air coming in and the air going out of the intercooler are the same. You will get good power for a bit and then it will fall off and you could detonate.

Water To Air Intercooler (Like On the Cobalt SS)

Uses a heat exchanger, Radiator, Pump and Coolant. The Air charge heat is transferred to a heat exchanger and taken to a radiator by the coolant with a pump. Normally used where space is difficult.

/enginespics/32engine/SLK32intercooler.jpg)

Air To Air Intercooler (Like On Most Turbo Tuner Cars)

Like a Radiator except, Air is being cooled in the passages instead of coolant. Air passes through the internal passages and heat is transferred to the ambient air through the metal fins.

Alright, You want to Up the Boost and Up The HP, You have to think first. Every time you change something in a car to get performance, there are other things that will change as well, some (Most) of them are negative.

Oxygen is the only hard thing to put in an Engine...

More Fuel, No Problem,

Bigger Spark, No Problem.

Agreed. So Back to Chemistry.

Air is a mixture of Nitrogen and Oxygen. The Hotter a Gas is (In this case air) The fewer the number of atoms are present in that volume.

So

1 Ft/Cu of air at 100Deg will have many less molecules than. 1 Ft/Cu of air at Zero Deg.

Just by changing the temperature of the intake, you have made more HP because you have more Oxygen, so you can burn more Fuel.

Easy Fundamental Concept #1.

A Turbo and Supercharger both compress air. The action of compressing the air makes the air much hotter. The amount of heat depends on how efficient the compressor is but it can be calculated. The More pressure the compressor is making the hotter the air becomes.

Easy Fundamental Concept #2.

You want more boost, you get more heat. More heat equals less molecules per volume of air. So as you are compressing more air into the engine, you are not getting the same density of air and are not getting as much oxygen as you should for the volume.

The intercooler is designed to remove the heat caused by compression.

This reduces the negative effect of compressing air and Makes More Horsepower.

Reduces The Likeliness of Detonation.

Pressure Drop

Basically the loss or restriction that an intercooler has.

EG#1. To get 10.0 Psi at the engine after the intercooler the turbo has to push 11.0 Psi before.

That is an acceptable drop.

EG#2. To get 10 Psi at the engine after the Less Efficient intercooler the turbo has to push 13.0 Psi before.

That is not helping. To get the turbo to make the extra 3 Psi, it will be creating allot more heat than EG#1. So this intercooler is not capable for the Volume that is required to move with efficiency. It will eventually heat soak and the intake will start to heat up. OMG! The extra 3 Psi will cancel out with heat. Minimal Gains.

The Intercooler must be capable to move the volume of air with as little pressure loss as possible.

Heat Soak

Heat soak is simply when the intercooler is overwhelmed with constant high heat that it is not capable of dissipating. The longer the turbo makes boost, the hotter the intercooler will get hotter to the point where the air coming in and the air going out of the intercooler are the same. You will get good power for a bit and then it will fall off and you could detonate.

Water To Air Intercooler (Like On the Cobalt SS)

Uses a heat exchanger, Radiator, Pump and Coolant. The Air charge heat is transferred to a heat exchanger and taken to a radiator by the coolant with a pump. Normally used where space is difficult.

/enginespics/32engine/SLK32intercooler.jpg)

Air To Air Intercooler (Like On Most Turbo Tuner Cars)

Like a Radiator except, Air is being cooled in the passages instead of coolant. Air passes through the internal passages and heat is transferred to the ambient air through the metal fins.

#13

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

Alcohol / Water Injection

Alcohol/Water Injection

First, It does work. (So There, I said it)

Second, it should be considered as a Band-Aid for a larger design problem.

http://www.aquamist.co.uk/

The basic idea is that just like a Front Mount Intercooler... If you drop the temperature of the air going in the engine you have done a couple of things...

1. The Air Is Denser. (More Oxygen)

2. The Engine is less prone to Detonation

3. You can run Higher Boost with the same detonation threshold.

The basic idea is that a mixture of Water and Alcohol is dumped into the throttle body under boost. The mixture evaporates and has a cooling effect. It was very common in Supercharged WWII Fighter Planes to promote more reliable operations under emergency conditions... Notice that... Emergency Conditions...

The route of the original problem that caused you to seek the injection would be "Poor Design" of the basic system in question.

FMIC, CAI, More Efficient Compressor either Turbo or Supercharger.

So here is some Physics.

The idea of Forced Induction is to cram more oxygen in the engine.

Colder Air is more Oxygen,

More Air is More Oxygen.

More Air that is Hotter is the same or less Oxygen (closer to detonation too)

For the injection to work it must be dumped into the intake. The Volume of liquid will displace some of the air it is cooling. So the air is colder and denser, but the alcohol and water has displaced some of it, It cancels out a bit.

Abstract Thought Time, This is only an Example to illustrate the concept.

There is no magic in Physics. To get, you must Give too...

It's like changing the pulley on the supercharger to get 10 HP more, but in doing so you have put an additional 5 HP of draw on the belt and the heat is higher so that kills 3 HP too. You get 2 More HP and more strain on the car. Was it worth it, No. Had you just cooled the air more, you would have gotten your 2 HP without changing anything.

10 HP - 5 HP - 2 HP = Whoopee, 2 Shitty HP..

Brian's Take... Look into a more effecient Perminant Intercooler before looking into this idea.

First, It does work. (So There, I said it)

Second, it should be considered as a Band-Aid for a larger design problem.

http://www.aquamist.co.uk/

The basic idea is that just like a Front Mount Intercooler... If you drop the temperature of the air going in the engine you have done a couple of things...

1. The Air Is Denser. (More Oxygen)

2. The Engine is less prone to Detonation

3. You can run Higher Boost with the same detonation threshold.

The basic idea is that a mixture of Water and Alcohol is dumped into the throttle body under boost. The mixture evaporates and has a cooling effect. It was very common in Supercharged WWII Fighter Planes to promote more reliable operations under emergency conditions... Notice that... Emergency Conditions...

The route of the original problem that caused you to seek the injection would be "Poor Design" of the basic system in question.

FMIC, CAI, More Efficient Compressor either Turbo or Supercharger.

So here is some Physics.

The idea of Forced Induction is to cram more oxygen in the engine.

Colder Air is more Oxygen,

More Air is More Oxygen.

More Air that is Hotter is the same or less Oxygen (closer to detonation too)

For the injection to work it must be dumped into the intake. The Volume of liquid will displace some of the air it is cooling. So the air is colder and denser, but the alcohol and water has displaced some of it, It cancels out a bit.

Abstract Thought Time, This is only an Example to illustrate the concept.

There is no magic in Physics. To get, you must Give too...

It's like changing the pulley on the supercharger to get 10 HP more, but in doing so you have put an additional 5 HP of draw on the belt and the heat is higher so that kills 3 HP too. You get 2 More HP and more strain on the car. Was it worth it, No. Had you just cooled the air more, you would have gotten your 2 HP without changing anything.

10 HP - 5 HP - 2 HP = Whoopee, 2 Shitty HP..

Brian's Take... Look into a more effecient Perminant Intercooler before looking into this idea.

#16

Senior Member

Join Date: 07-17-05

Location: Western Massachusetts

Posts: 2,375

Likes: 0

Received 0 Likes

on

0 Posts

Hey brian. Is there anyway you can do a little write up on intercoolers on turbos ? i sorta know the basics but a more descriptive write up like yours would clear up everyting and make it easier on me. thanks man.

ryan

Edit. oh ya u do have the fmic lol. my b. thanks man

ryan

Edit. oh ya u do have the fmic lol. my b. thanks man

#19

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Cobalt30

Hey brian. Is there anyway you can do a little write up on intercoolers on turbos ? i sorta know the basics but a more descriptive write up like yours would clear up everyting and make it easier on me. thanks man.

ryan

ryan

For sure, if you look a couple of posts up, I have reserved a spot for FMIC.

Front Mount Intercooler

Watch for it in a couple of days and I'll PM you when I get it done...

#24

Senior Member

Thread Starter

Join Date: 11-14-05

Location: www.mp5t.com

Posts: 4,425

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by p7x

I was just about to post the same thing...goddammit

#25

Senior Member

Join Date: 01-15-05

Location: Ottawa

Posts: 5,126

Likes: 0

Received 0 Likes

on

0 Posts

Twincharging etc

Here's a lil more It might have some stuff repeated but it explains a lil bit about twincharging

Supercharging

The centrifugal supercharger is the only type of after market supercharger that has been fitted to a 4th Gen F-body at the time of this writing. As they are not mounted on top of the intake manifold (as any of the positive displacement type blowers are) they are easier to retrofit to vehicles that started their lives NA. It would not be economically feasible to adapt an M90 roots supercharger from a GTP to a 4th Gen F-body. If you are not satisfied by that statement, do a search or build the kit yourself.

By the way, a turbo (aka turbosupercharger, aka turbocharger) is a form of supercharger that is driven by exhaust gases. It is technically a subtype of superchargers because the defining feature of a supercharger is that it compresses air. The method of driving the compressor is irrelevant to the definition.

• Roots Compressor

• Lysholm (aka Screw) Compressor

• Centrifugal Compressors

Turbocharging

Turbochargers are simply exhaust driven centrifugal superchargers. The compressor is directly linked to a turbine that is placed within the exhaust system. The compressor section of a turbo is generally smaller than the compressor of its cousin the crank driven centrifugal supercharger because it is going to spin at 10 times the RPM. The turbine looks like the compressor section of the turbo, except that the flow path is reversed and energy is taken out of the high kinetic energy exhaust gases in order that energy may be put into the intake charge (via compression). It is the turbine (in conjunction with the wastegate) that allows a turbo to function at many different RPMs at a single of engine speed. This allows greater tunability as compared to a crank driven supercharger. Ideally, the turbine is placed as close to or on the exhaust manifolds. This is so that the exhaust gases will lose the least amount of energy by the time they interact with the turbine.

Given that English as a language is somewhat imprecise, and that terms in science may not have exactly the same meaning as they do in everyday usage, there are many claims made about what exactly drives the turbine. Heat is the term that the layman uses when trying to describe the driving force of the turbine. However, whereas in everyday usage heat may be synonymous with temperature, in science it strictly means the flow of energy between systems when no work is done. If the interaction of the exhaust gas with the turbo was limited to heat exchange, then we would have placed an expensive mechanical device in our exhaust path that would sit around and do nothing. A more scientifically precise term for what drives the turbine is kinetic energy. Temperature, which everyone is familiar with, is the measure of the average kinetic energy of a system.

I have also seen it claimed that it is not just kinetic energy that drives a turbo, but also pressure. As with many other areas in physics, it is possible to describe or calculate effects using different terms. Saying that pressure gradients drive a turbine would be an accurate description, however saying that pressure and kinetic energy drives a turbine is redundant. Pressure is commonly known to most as Force per Area (for example, the SI unit of pressure is the Pascal, which is a Newton per square meter). However, it is also possible to express pressure of a fluid as Energy per Volume. Thus, pressure can be thought of as an energy density. The change in energy density (pressure) before and after the turbine tells you the same thing as the change in energy of the gas before and after the turbine.

Note: In a way you can think of two different types of kinetic energy in the exhaust path. That is to say, the two types are the movement of the gas as a whole from the manifold out to end of the tailpipe, and the random movement of each individual gas particle (which is measured as temperature). When I stated that the turbine is powered by the “kinetic energy” of the exhaust gas, it could be a combination of either of the two, but is principally the temperature component.

• Wastegates

• Blow off valves

• Remote Mounted Turbochargers

• Variable Nozzle Turbine

Twincharging

Twincharging is using two compressors in series to compress the air. This is different than sequential setups which use one compressor stage at low RPMs and switch to the next at higher RPMS. Such setups usually take the form of a turbo feeding a supercharger, although technically you could feed the turbo from the supercharger or use two superchargers or two turbos (dual stage superchargers or two turbos in series were commonly used on WWII fighter aircraft). Obviously a system with two compressors will inherently be more complex and expensive than a system with one. Why bother? There are some real benefits to twincharging at high boost levels, and a car like the supercharged Wbody already has a roots blower so a twincharged setup is nearly 50% complete.

Roots blowers, like on the Wbody, are positive displacement units. Although they can provide good low RPM boost, they are the most inefficient of all compressors. Eaton’s twisted rotor design makes up for some of the limitations, but adiabatic efficiency is still limited to around the 60% range. This mean that increases in boost on the stock unit disproportionately increase intake temperatures as compared with a centrifugal compressor (such as in a turbo, which can operate in the 70 to 75% efficiency range).

Imagine that you want to run 20psi of boost on your Wbody. Theoretically, you could spin the Eaton until it produces that amount of boost. However, given low efficiency, you will have some pretty hot air. How hot you ask? Let’s assume we are at sea level, the air temperature is 80F, and the compressor efficiency is 0.6 (60%). At 20psi of boost, the inlet of the supercharger will see about 14.7psi absolute pressure, and the outlet will be at 34.7psi absolute. This is a pressure ratio of about 2.36 (34.7/14.7). With these conditions, the air fed into the cylinders will be 327.5F. You could almost bake a cake.

What would happen if we fed the roots blower with a turbo? We will use the turbo to add 10psi of boost and the roots to add 10psi to get the total of 20psi of boost. We will keep the above assumptions and add that the turbo is at 70% efficiency. The turbo itself will be operating at a pressure ratio of 1.68 (24.7/14.7). The turbo inlet temperature is 80F and the outlet temperature will be 201.9F.

The air from the turbo then goes to the roots supercharger. The roots supercharger compresses the already compressed air. The supercharger’s inlet temperature is 201.9F, and the inlet pressure is 24.7psi. Thus to add another 10psi of boost, it will operate at a pressure ratio of 1.4 (34.7/24.7). The outlet temperature will thus be 313.3F. We have reduced the inlet temperature to the motor by 14F, which isn’t surprising since we added a more efficient compressor to do half the work. However, we haven’t quite justified the twincharger setup.

Now, what would happen if we added an intercooler between the turbo and the supercharger? (The intercooler received its name because it was originally used between compressor stages on aircraft). Let’s assume the intercooler is 80% efficient and will have a pressure drop of 1psi. To make up for the drop, we will use the turbo to produce an extra 1psi so that in the end the boost at the motor is still 20psi.

Adhering to our original assumptions, the turbo is now operating at a pressure ratio of 1.75 (25.7/14.7) with an inlet temperature of 80F and an outlet temperature of 211.6F. So far, we have an extra 10F of temperature in the air.

The intercooler will have an inlet temperature of 211.6F, but an outlet temperature of only 106.3F with a “pressure ratio” of 0.96 (24.7/25.7).

The roots supercharger in this case will be starting with the same inlet pressure, but a much lower inlet temperature. With the same pressure ratio, 1.4 (34.7/24.7), the outlet temperature of the supercharger is now only 201.4F. That is over 125F less than if we had used the supercharger by itself to compress the air.

The obvious question is then why not rip off the supercharger and just use a big turbo and intercooler to make the boost? You may be able to save another 70F of air temperature, but it will be difficult to find a turbo that will spool to a 21psi boost as quickly as one that only has to get to 11psi. Bottom line is that if you can tune it, which is difficult, a twincharged setup can be very effective.

Equations:

T2 = T1 + [T1*(P2/P1)^0.283 – T1] / CE

Where T1 is the ambient temperature, T2 is the outlet temperature, P1 is the inlet absolute pressure, and P2 is the outlet absolute pressure. The temperatures must be in units of Kelvin or Rankine.

And

Tout = Tin – IE*(Tin – Tamb)

Where Tin is the inlet temperature (K or R), Tamb is the ambient temperature, Tout is the outlet temperature and IE is the intercooler efficiency.

And finally

K = [(F – 32)*0.5555] +273.15

To convert Fahrenheit to Kelvin.

Electric Turbochargers

These come in various names, but the tech is usually the same. Various individuals market electrically driven fans that they pawn off as "electric turbos" or "electric superchargers." Most of them claim that these can create 2-3psi. However, typically any pressure that they might create is at low airflow. For example, a 3.8L motor with a volumetric efficiency of 75% will need more than 300CFM at 6000RPM.

It is unlikely that these systems will do anything more than cause a restriction in the intake.

That said, the concept of an electrically driven supercharger is nothing new and is theoretically possible. There are experimental setups that are in development; however, there is a need for greater electrical storage in the form of auxiliary batteries and capacitors, high output electric motors, and larger alternators. These systems currently can only be used in small bursts (15 seconds or so) before the electric storage media needs to be recharged. While an interesting experiment, at present technology they present little advantage over conventional superchargers.

Intercoolers

All this air compression will cause the temperature of intake charge to increase (i.e. can’t beat thermodynamics). Intercoolers are an attempt to bring the temperature of the air closer to ambient. Lower temperature air decreases the chance of detonation and also results in a higher flow rate through the engine. Higher flow rate is proportional to power output. Intercoolers received their name because some piston engine era warplanes utilized twin stage superchargers in order to maintain engine power at high altitudes. Even though many of those aircraft ran on 160 octane leaded fuel, heating of the intake air was a concern (see Rolls Royce Merlin engine design). A device, essentially a radiator, was placed between the first and second supercharger stages, and the “intercooler” was born. A similar device could also be placed after the second stage and was called the “aftercooler.” Although technically what we see on the automobiles today are more directly related to aftercoolers (some supercharger kits refer to them in this way) apparently intercooler sounds ‘cooler’ (pardon the pun) and that is what description we commonly use for these little radiators.

The two main types of intercoolers are the air-to-air and air-to-water types; the main difference is which medium accepts heat from the intake charge.

Air-to-air intercoolers exchange heat between the intake charge and the ambient air. Efficiency is commonly in the neighborhood of 80%. Air-to-air intercoolers must be placed in a location with sufficient airflow or they will not be able to effectively exchange heat. Two subclasses of air-to-air intercoolers are the cheaper tube and fin design, and the more robust and efficient bar and plate design. The main advantage of an air-to-air intercooler is simplicity of design.

Air-to-water intercoolers may operate at efficiencies greater than 100% if the water is at a temperature below ambient. These systems do not need to be placed in the path of airflow, so there is some freedom in choosing a location for it within the vehicle. The actual intercooler portion of the system is generally smaller than a comparable air-to-air intercooler. Unfortunately, air-to-water systems are more complex in that they need a coolant reservoir and some method to extract heat from the coolant.

Water, Alcohol, and Nitrous Injection

First off, this is not a section about nitrous oxide in general. The section is to elaborate on a several methods in which to cool the intake charge of a forced induction motor.

As stated in the previous section, high intake temperatures are something that should ideally be avoided. Injection of water, alcohol and nitrous oxide into the intake path are all additional strategies that may be employed. Some people use water or alcohol injection in addition to an intercooler, whereas other people may use it by itself.

Water is has many unique properties, but one of them is not that it will burn in your cylinder. So why would you want to inject it? It turns out one of the properties it has is a relatively high specific heat, especially in liquid form. Specific heat is a term that describes how much energy it takes to raise a given amount of a substance a given temperature. Water is injected into the intake tract at some point before the intake manifold. Generally the farthest away without injecting before the supercharger, turbocharger, or intercooler is considered ideal. As water is injected in the liquid form, energy is taken out of the intake air and placed into the water molecules. This energy transfer causes the intake air to decrease its temperature, and causes the water to heat, evaporate, and then most likely to heat some more in the vapor phase. The amount of temperature reduction of the air and the amount of increase in water temperature depends on the original temperatures of both mediums, and the amount of water injected. The sole function of water injection, therefore, is to lower intake temperatures and hopefully reduce the risk of detonation. Any power increase from the use of water injection is due to more boost or more aggressive timing.

Alcohol injection works in a similar fashion, except for a few important differences. The specific heats of methanol, ethanol, and isopropyl alcohol are all less than the specific heat of water. The also are more volatile. But unlike water, all three alcohols can participate in combustion. Additionally all three have an octane rating of slightly more than 100. Therefore alcohols have the potential to richen the air/fuel mixture and increase the octane rating (if you are running less than 100 that is). A mixture of water and alcohol can be used if additional cooling is required.

Nitrous oxide injection cools the intake air in a completely different manner. It is generally not used as a simple intake cooling method, but since it does have that effect I have decided to include a small discussion here. In the tank it is stored at high pressure. Injection into the intake causes rapid expansion into the gas phase. This expansion results in rapid cooling of the nitrous oxide and air mixture. A note of caution, however, is that whereas alcohol injection richens the air fuel mixture, nitrous oxide will tend to lean the mixture. Therefore additional fuel must be provided to the motor.

Turbocharger vs. Supercharger

In simplistic terms, the engine functions as an air pump. The more air and fuel that is pumped through, the more power you can make. In order to pump the air, pressure on the intake side must be higher relative to pressure going out the exhaust. In a naturally aspirated engine, valve timing events are used to create a pressure. Since you are reading this guide, you are probably not interested in naturally aspirated engines, so we can leave it at that. That said, we can all agree that it makes no sense to build a naturally aspirated performance engine. From a performance standpoint, it would generally make sense to use some means to pressurize the intake, while using some means to decrease the pressure in the exhaust path. The second part is easy; almost everyone and their brother has some type of exhaust work. The first job is a little trickier. Fortunately we have superchargers (and turbos) to save the day.

A crank driven supercharger will most definitely increase the pressure on the intake side of the engine. Since it is limited to the intake track, it will not adversely affect the pressure in the exhaust. The pressure on the intake side should always be greater than the pressure in the exhaust. However, power doesn’t come free, and you must use some of that newfound torque to spin the supercharger. How much that takes is calculable, but is purely academic because significant power is netted. In the case of positive displacement superchargers, boost can be had at very low RPMs, and in the case of the centrifugal and screw supercharger, good efficiency can be had. Other reasons to choose a supercharger are that the retrofit to an NA car should be smoother because there are no changes to be made to the exhaust path. The power curve is predictable because boost is largely dependent on RPM of the motor and not some less tangible factor such as engine load.

Now why would anyone want a turbo? Turbo systems are more complex because they require revision to the intake and exhaust sides of the motor. From the air pump standpoint, at first glance they seem to be inferior to a supercharger as you are placing a restriction in the exhaust flow path (i.e. the turbine). And given what we know of centrifugal compressor efficiency at low RPMs, there may be a significant portion of the rev range before the turbo will reach threshold and begin to create boost (this is what “lag” is). However the relative independence from engine RPM is the turbo’s greatest advantage over any other supercharger type. Boost can be reset with ease, and therefore tunability is also greatly increased as compared to a crank driven unit. While the adiabatic efficiency of the compressor may not be as great as that of a screw type supercharger, the drive mechanism is much more efficient, as a turbo relies on utilization of largely wasted kinetic energy in the exhaust gases. All of this combines to form a versatile, tunable unit that has the potential to make more power than a crank driven supercharger.

So a turbo must be superior to a crank driven supercharger, right? If that was the case the crank driven supercharger would have died out long ago. For all out power the turbo reigns supreme, but life unfortunately is full of compromises. Packaging is a huge concern during a retrofit of forced induction onto an NA motor, and in that instance the crank driven supercharger has the turbo beat handily. The user must decide on his or her priorities and decide from there.

LINK

Supercharging

The centrifugal supercharger is the only type of after market supercharger that has been fitted to a 4th Gen F-body at the time of this writing. As they are not mounted on top of the intake manifold (as any of the positive displacement type blowers are) they are easier to retrofit to vehicles that started their lives NA. It would not be economically feasible to adapt an M90 roots supercharger from a GTP to a 4th Gen F-body. If you are not satisfied by that statement, do a search or build the kit yourself.

By the way, a turbo (aka turbosupercharger, aka turbocharger) is a form of supercharger that is driven by exhaust gases. It is technically a subtype of superchargers because the defining feature of a supercharger is that it compresses air. The method of driving the compressor is irrelevant to the definition.

• Roots Compressor

• Lysholm (aka Screw) Compressor

• Centrifugal Compressors

Turbocharging

Turbochargers are simply exhaust driven centrifugal superchargers. The compressor is directly linked to a turbine that is placed within the exhaust system. The compressor section of a turbo is generally smaller than the compressor of its cousin the crank driven centrifugal supercharger because it is going to spin at 10 times the RPM. The turbine looks like the compressor section of the turbo, except that the flow path is reversed and energy is taken out of the high kinetic energy exhaust gases in order that energy may be put into the intake charge (via compression). It is the turbine (in conjunction with the wastegate) that allows a turbo to function at many different RPMs at a single of engine speed. This allows greater tunability as compared to a crank driven supercharger. Ideally, the turbine is placed as close to or on the exhaust manifolds. This is so that the exhaust gases will lose the least amount of energy by the time they interact with the turbine.