Lil Blacky’s official TVS build thread(long post)

#251

I would like to have a discussion on this but won't clog up your build thread with it. First, this design is of a Swedish Engineer, not GM. I have always wondered who's idea it was to go to a dual pass and why. I have seen so many issues in this system after the GM design.

When you can, you enter high and exit low when cooling something. The opposite when absorbing heat due to the natural physics of heat movement. Look at any radiator that is a down flow. Water always comes in high and exits low. As the water cools it will naturally want to drop. You don't try to force anything the opposite direction it wants to go naturally.

Looking forward to seeing the results.

When you can, you enter high and exit low when cooling something. The opposite when absorbing heat due to the natural physics of heat movement. Look at any radiator that is a down flow. Water always comes in high and exits low. As the water cools it will naturally want to drop. You don't try to force anything the opposite direction it wants to go naturally.

Looking forward to seeing the results.

#253

Senior Member

Thread Starter

THeres been quite a few results already. The highest Jason got was 113-123 iats2 in summer weather when he would track it. That’s pretty incredible. Mine with dual pass, and phenolic spacer would get into the 140s in the summer during one pull.

#254

Senior Member

Thread Starter

#260

the water does need some time in there to absorb heat.

not sure how fast the pump is pushing water through there. clearly the stock single pass method isn't better than the aftermarket dual pass. has anyone done practical testing about this single pass method?

not sure how fast the pump is pushing water through there. clearly the stock single pass method isn't better than the aftermarket dual pass. has anyone done practical testing about this single pass method?

#261

Senior Member

iTrader: (6)

The water does not need "time" to absorb heat. It's a continuous process, a few posts up the OP noted some temp differences. The stock single pass isn't a true single pass iirc, HGT should be able to discuss this more as he's more familiar with the setup and coolant flow paths that I can recall right now.

#263

Senior Member

Thread Starter

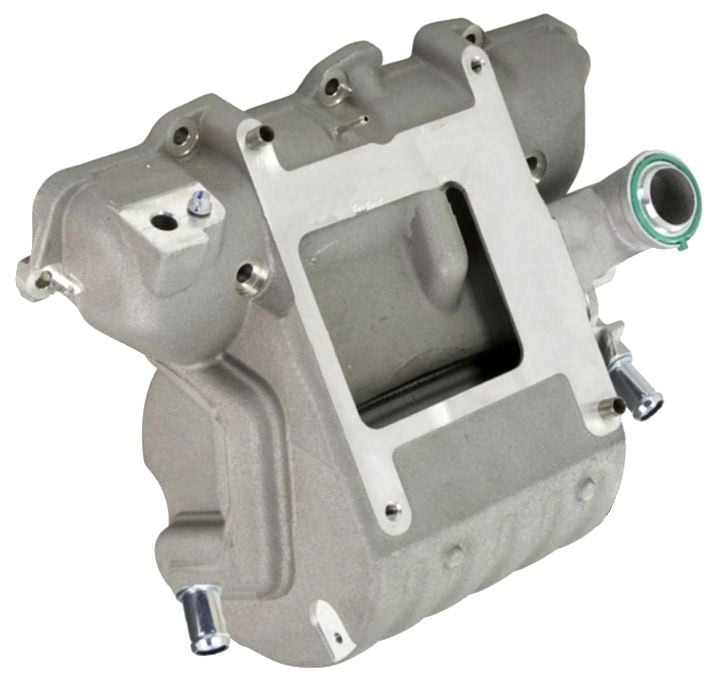

The coolant/water needs to spend the least amount of time possible in there. Hot coolant/water means hight iat2 and that means loss of power. My oats are going to be so low with my setup and my icebox. And jason Widdowson makes these and has sold a ton. Results have been posted many times and there’s no better cooling mod than his single pass. He also makes heat exchangers and sells different ic pumps. I myself am running two ic pumps. One stock and one viramax.

#264

Senior Member

iTrader: (6)

The heat transfer occurs at the surface layer, if the water is moving faster (not caviating though air is a good insulator) more molecules of water contact the metal taking a little heat at each interaction. Forced convection heat transfer coefficient increases with higher agitation to a point.

#265

This is from a very good in depth write up on cooling systems.

Myths

For those that cling tenaciously to myths, I am going to take one last crack at forever dispelling the Granddaddy of them all when it comes to cooling systems.

The myth is stated as either:

Coolant can be pumped too fast through the engine for it to absorb enough heat, or

Coolant can be pumped too fast through the radiator for it to cool properly, or

Cooling can be improved by slowing the flow of coolant through the radiator so it cools more completely.

NONE of these are true. The simple truth is that higher coolant flow will ALWAYS result in higher heat transfer and improved cooling system performance.

The reason the myth is so persistent, is that: a) without knowledge of fluid dynamics and laws of thermal conduction it does make a kind of intuitive sense and b) it is based on a tiny kernel of truth, but that kernel of truth does not explain the overall system behaviour and so, interpreted out of context, leads to a completely erroneous conclusion.

So, let's start with the tiny nugget of truth. If you had a sealed rad (no flow) full of hot coolant, and subjected that rad to airflow, yes, the longer you left the coolant in the rad, the more it would cool. However, if you were to plot that cooling over time, you would find that the RATE at which the cooling takes place is an exponential curve that decreases with the temperature difference between the hot coolant and the air. Put another way - when the temperature difference (delta-T) between the hot coolant and the airflow is large, heat transfer (cooling) initially takes place very, very quickly (almost instantaneously). But as that happens, and the coolantcools, the delta-T becomes less, and the RATE at which further cooling happens gets less and less until the point where the coolant and air are almost the same temperature and continued cooling takes a very long time. This is Newton's law of cooling. To illustrate this, recall my "quenching steel in a bucket" analogy.

A good example of this law can be seen when quenching a red-hot piece of steel in a bucket of water. At first, the temperature difference (delta-T) between the red-hot steel and the water is huge - therefore the initial heat transfer occurs at a great rate - the steel initially cools very fast - almost instantaneously. However, after this initial cooling, the delta-T is much smaller, so the remaining cooling occurs much more slowly. If you removed the steel after a second or two - it has cooled a lot - but it will still be warm. To continue cooling the steel to the temp. of the water, you have to leave it in there quite a bit longer - because as it cools - the rate of cooling continually decreases as well. In short - initial cooling is fast, but subsequent cooling occurs more and more slowly until cooling that last little bit takes a long time.

So what does this mean? Basically it means, the longer the coolant stays in the rad, the less efficient the cooling that takes place is - to the point that the rate of cooling is so slow as to be detrimental to overall system cooling. Better to dump the big load of heat right away and go back quickly for another load than hang about waiting for a last little bit of insignificant cooling to happen.

To understand fully, we have to put our rad back into the whole system where coolant is flowing and consider the effects of flow rate on the system as a whole.

Slowing the coolant in the rad may allow that coolant (the coolant in the rad) to dissipate a little more heat (but not much), and at an ever decreasing rate (exponentially decreasing) BUT since the cooling system is a closed-loop system, you also have to consider what’s happening outside the radiator if you slow the flow - especially to the coolant in the engine. If you slow the coolant through the rad, you slow the coolant through the engine too. And this coolant is subject to the same laws - the greater the initial temperature difference between the engine and the coolant, the greater the rate at which the coolant absorbs the heat from the engine. BUT - if we leave the coolant in contact with the engine for longer by slowing the flow through the rad, the delta-T between engine and coolant decreases and with it the rate at which the coolant in the engineabsorbs the heat from the engine. Meanwhile the engine is banging away producing heat, but the coolant is absorbing it at a slower and slower rate - that heat has to go somewhere, and since the slow coolant is becoming less efficient at absorbing it - it stays in the metal - and the metal overheats!

Meanwhile, back at the rad, you're wasting time trying to shed the last little bit of heat when the delta is small instead of carrying away the “big chunks” of heat. And the situation just gets worse and worse in a downward spiral.

Imagine emptying a truckload of sand using a small wide-mouth container vs. a larger narrow-mouth container. The job will get done quicker by making more trips with the smaller container that takes less time to fill and empty, rather than taking the time to fill the larger narrow-mouth container and then taking the time to empty it – that extra in the larger narrow-mouth container isn’t worth it – better to dump the load and go back for more.

Or, how about this for those who are fans of elaborate metaphors

Imagine a circular train track with two stations opposite each other and rail cars that fill the whole track. One station has an endless supply of passengers trying to get on and the other is where they get off and disperse. Your job as the train driver is to move as many people as possible to keep them from accumulating at the embarkation station and crushing each other. Now imagine the passenger cars are funnel-shaped on the inside. This means the first big batch of people can get on and off quickly, but completely filling the car takes a lot longer as people have to squeeze into the narrower portion.

So, you could drive the train slowly, only moving along after each car has completely filled and completely emptied… but efficiency will be greatly reduced as it takes so long to get those last few people on or off the car – meanwhile the never ending supply of people at the embarkation station never stops and the system backs up and the people get crushed because, even though more people get on or off each car, the whole system is less efficient.

OR

You could drive the train fast, quickly loading and unloading the big, easy-to-fill, portion of each car, forget about the smaller portion, and keep picking up and dumping off a large group of passengers as fast as you can. In fact – the faster you go, the better…the more efficient at moving large numbers of people the systemwill be. Screw the last stragglers – they’re insignificant and won’t help you – just move the big chunk and move on, going back for more, more often.

So – you want high flow / high (turbulent) speed so it picks up and dumps off the most heat quickly – it’s inefficient to try and shed the last little bit of heat when the delta is small, and can lead to overheating because you’re wasting time not carrying away the “big chunks” of heat.

Last edited by Henry3959; 01-29-2018 at 02:12 PM.

#266

its not a myth. basic race car cooling systen design takes into account coolant speed through radiator

ive seen engines overheat without thermostats because the coolant isn't in the radiator long enough to cool off.

ive seen engines overheat without thermostats because the coolant isn't in the radiator long enough to cool off.

The following users liked this post:

Viperoni (01-30-2018)

#269

i read it

the bottom line is the coolant needs time in the radiator to cool off.

i had a jeep cherokee with the i6 and the thermostat went bad i ran it without to get a new one. overheated idling w/ fans on...

you can believe whatever you want. lots of people have tried to run their race cars without thermostats and they end up overheating

the bottom line is the coolant needs time in the radiator to cool off.

i had a jeep cherokee with the i6 and the thermostat went bad i ran it without to get a new one. overheated idling w/ fans on...

you can believe whatever you want. lots of people have tried to run their race cars without thermostats and they end up overheating

#270

true, its best the coolant goes through the lav cores as fast as possible because its supposed to be doing the cooling rather than being cooled. its basically the opposite of being in the radiator.

when it goes into the heat exchanger the air is doing the cooling and the coolant is being cooled. obviously if it sits in there longer it will be cooler than if it went through fast.

more/faster air through radiator = better cooling

more/faster coolant through lav cores = better cooling.

when it goes into the heat exchanger the air is doing the cooling and the coolant is being cooled. obviously if it sits in there longer it will be cooler than if it went through fast.

more/faster air through radiator = better cooling

more/faster coolant through lav cores = better cooling.

#271

Senior Member

iTrader: (6)

Anyways thats enough of jamming up the build thread on this.

#272

Senior Member

iTrader: (6)

i read it

the bottom line is the coolant needs time in the radiator to cool off.

i had a jeep cherokee with the i6 and the thermostat went bad i ran it without to get a new one. overheated idling w/ fans on...

you can believe whatever you want. lots of people have tried to run their race cars without thermostats and they end up overheating

the bottom line is the coolant needs time in the radiator to cool off.

i had a jeep cherokee with the i6 and the thermostat went bad i ran it without to get a new one. overheated idling w/ fans on...

you can believe whatever you want. lots of people have tried to run their race cars without thermostats and they end up overheating

Removing a t-stat changes the flow throughout the other channels, the t-stat becomes a resistance point to allow flow to hit other zones. We're talking about a single passageway system, you're talking about changing flow to other areas.

The following users liked this post:

Viperoni (01-30-2018)

#274

Sounds like the coolant system wasn't sized correctly. There is only so much heat that can be transferred even without a t-stat. There is a lot of thermodynamics and fluid dynamics going on, but always heat transfer is increased with increased flow, hence why a fan or a breeze in cold causes you to loose heat faster and it seems colder. There isn't a point when the wind in blowing so fast you stop being cooled faster. Now in fluid systems if you introduce air by turbulence at the impeller it's possible to decrease heat transfer but it's not because of flow, its because air is a good insulator.

Anyways thats enough of jamming up the build thread on this.

Anyways thats enough of jamming up the build thread on this.

increased flow by the cooling force is going to cool better. but if you move what needs to be cooled faster then no it doesnt work.

to go with your analogy, with your hand out the window, leave it for 2 seconds, then leave it for 30 seconds. it'll be cooler after 30 seconds. same deal with coolant in a radiator.

#275