P1101

#1

Senior Member

Thread Starter

Join Date: 08-25-08

Location: Ofallon,MO

Posts: 737

Likes: 0

Received 0 Likes

on

0 Posts

P1101

Hey whats exactly does this mean? I know its like performance intake code or something like that but is there anything more detailed that anyone would know about? For those who remember the boost issue still is not gone... Throwing 3 codes P1101,P0300, P0171

Justin

Justin

#2

Senior Member

This is what it says

The PCM detects that the actual measured airflow from the MAF, SCIP, and TP is not within range of the calculated airflow that is derived from the system of models for more than 0.5 second.

What type of intake do you have ?

You must have a bad air leak somewhere ,check the vacuum lines.

The PCM detects that the actual measured airflow from the MAF, SCIP, and TP is not within range of the calculated airflow that is derived from the system of models for more than 0.5 second.

What type of intake do you have ?

You must have a bad air leak somewhere ,check the vacuum lines.

#4

Senior Member

This is how it works:

Operation

Supercharger boost pressure is regulated to prevent engine and drive train damage. When the engine is operating under high boost conditions, the powertrain control module (PCM) limits boost pressure to 83 kPa (12 psi). The PCM disables boost under the following conditions:

When reverse gear is selected

When the engine coolant temperature (ECT) is excessively high

When drivetrain abuse is detected (Open to interpetation)

When the vehicle is decelerating

If an intercooler pump failure is detected (easy one to check)

If the intake air temperature (IAT) sensor 2 becomes excessively high

Under heavy load in first and second gear at engine speeds above 5,800 RPM (rev limiter I think but not sure)

The PCM controls boost pressure by using the boost control solenoid. The boost control solenoid is normally an open valve. Under most conditions, the PCM commands the boost control solenoid to operate at a 99-100 percent duty cycle. This keeps the solenoid valve closed and allows only inlet vacuum to control the position of the bypass valve. At idle, engine vacuum is applied to the upper side of the bypass valve actuator, counteracting spring tension to hold the bypass valve open. As engine load is increased, engine vacuum is decreased, causing the spring in the bypass valve actuator to overcome the applied vacuum, closing the bypass valve and allowing the boost pressure to increase. The bypass valve starts to close when the vacuum measures 250 mm Hg (10 in Hg) and is fully closed at 90 mm Hg (3.5 in Hg). When reduced boost pressure is desired, the PCM commands the boost control solenoid to operate at a 0 percent duty cycle. This opens the solenoid valve and allows boost pressure to enter the bypass valve actuator at the lower side to counteract the spring tension, opening the bypass valve and recirculating excess boost pressure back into the supercharger inlet.

Results of Incorrect Operation

An open boost control solenoid control circuit, an open ignition 1 circuit, or boost control solenoid valve stuck open will cause reduced engine power, especially during wide open throttle operation.The boost control solenoid control circuit shorted to ground, boost control solenoid valve stuck closed or a restriction in the boost source or signal hoses will cause full boost to be commanded at all times and a possible overboost condition during high engine load situations.

A restriction in the vacuum signal hose to the bypass valve actuator or a stuck closed bypass valve will cause a rough idle and reduced fuel economy.

Operation

Supercharger boost pressure is regulated to prevent engine and drive train damage. When the engine is operating under high boost conditions, the powertrain control module (PCM) limits boost pressure to 83 kPa (12 psi). The PCM disables boost under the following conditions:

When reverse gear is selected

When the engine coolant temperature (ECT) is excessively high

When drivetrain abuse is detected (Open to interpetation)

When the vehicle is decelerating

If an intercooler pump failure is detected (easy one to check)

If the intake air temperature (IAT) sensor 2 becomes excessively high

Under heavy load in first and second gear at engine speeds above 5,800 RPM (rev limiter I think but not sure)

The PCM controls boost pressure by using the boost control solenoid. The boost control solenoid is normally an open valve. Under most conditions, the PCM commands the boost control solenoid to operate at a 99-100 percent duty cycle. This keeps the solenoid valve closed and allows only inlet vacuum to control the position of the bypass valve. At idle, engine vacuum is applied to the upper side of the bypass valve actuator, counteracting spring tension to hold the bypass valve open. As engine load is increased, engine vacuum is decreased, causing the spring in the bypass valve actuator to overcome the applied vacuum, closing the bypass valve and allowing the boost pressure to increase. The bypass valve starts to close when the vacuum measures 250 mm Hg (10 in Hg) and is fully closed at 90 mm Hg (3.5 in Hg). When reduced boost pressure is desired, the PCM commands the boost control solenoid to operate at a 0 percent duty cycle. This opens the solenoid valve and allows boost pressure to enter the bypass valve actuator at the lower side to counteract the spring tension, opening the bypass valve and recirculating excess boost pressure back into the supercharger inlet.

Results of Incorrect Operation

An open boost control solenoid control circuit, an open ignition 1 circuit, or boost control solenoid valve stuck open will cause reduced engine power, especially during wide open throttle operation.The boost control solenoid control circuit shorted to ground, boost control solenoid valve stuck closed or a restriction in the boost source or signal hoses will cause full boost to be commanded at all times and a possible overboost condition during high engine load situations.

A restriction in the vacuum signal hose to the bypass valve actuator or a stuck closed bypass valve will cause a rough idle and reduced fuel economy.

#5

Senior Member

Thread Starter

Join Date: 08-25-08

Location: Ofallon,MO

Posts: 737

Likes: 0

Received 0 Likes

on

0 Posts

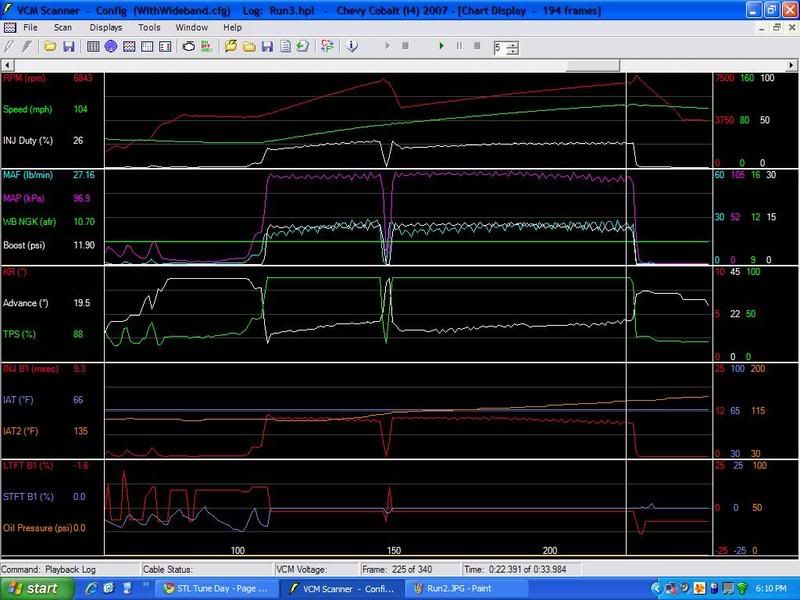

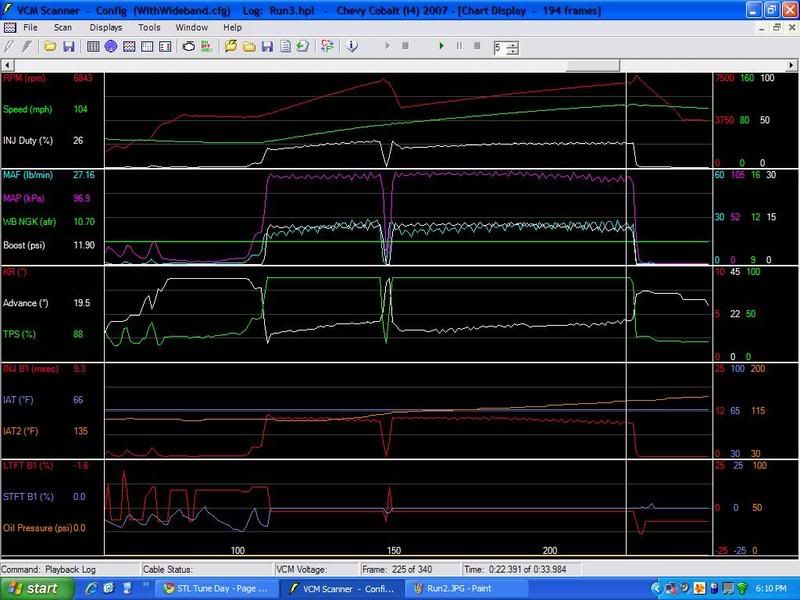

here are some data logs of 3 pulls and my issue with boost...SC and TB gasket have been replaced...Talk is that it could be the acuator on the SC or i belive it might be the MAF

My IAT's seem good so the pump is ruled out and i have checked that main times and its running...Any thoughts...Would the SC acuator make the sensors go crazy like this? These conditions only apply under boost at WOT

My IAT's seem good so the pump is ruled out and i have checked that main times and its running...Any thoughts...Would the SC acuator make the sensors go crazy like this? These conditions only apply under boost at WOT

#6

Member

Join Date: 03-08-07

Location: queens village, ny

Posts: 341

Likes: 0

Received 0 Likes

on

0 Posts

This is what it says

The PCM detects that the actual measured airflow from the MAF, SCIP, and TP is not within range of the calculated airflow that is derived from the system of models for more than 0.5 second.

What type of intake do you have ?

You must have a bad air leak somewhere ,check the vacuum lines.

The PCM detects that the actual measured airflow from the MAF, SCIP, and TP is not within range of the calculated airflow that is derived from the system of models for more than 0.5 second.

What type of intake do you have ?

You must have a bad air leak somewhere ,check the vacuum lines.

P0300-The PCM is detecting a crankshaft rotation speed variation indicating a misfire sufficient to cause emission levels to exceed mandated standards.

P0171-fuel trim system lean

Thread

Thread Starter

Forum

Replies

Last Post