Camshaft Position HOW TO????

#1

Camshaft Position HOW TO????

I've been having this issue for a while now since my motor swap.

I have a camshaft position code. I did my motor swap and just put that sensor/module back in all Willie Nillie. Didn't know it was important about it's position it actually went in.

So the Saab Motor I have does still accept the hex key and all, but I have no clue how to get the sensor/hex in correctly.

Anyone know of a how to or something around here that touches on that subject???

I'm getting pissed off with heavy backfiring and long start-ups now from the motor thinking the sensor is in a different phase.

Help Bratboy90!!!

I have a camshaft position code. I did my motor swap and just put that sensor/module back in all Willie Nillie. Didn't know it was important about it's position it actually went in.

So the Saab Motor I have does still accept the hex key and all, but I have no clue how to get the sensor/hex in correctly.

Anyone know of a how to or something around here that touches on that subject???

I'm getting pissed off with heavy backfiring and long start-ups now from the motor thinking the sensor is in a different phase.

Help Bratboy90!!!

#2

Thenotch in the hex key needs to be in the 4 o'clock position, with the #1 piston at TDC on the compression stroke. There should be a timing mark on the front of the timing chain cover that lines up with a notch on the back side of the crank pulley, it is out of view but you can feel it and line it up by touch. Don't do what I did and put the cam pos sensor in 180* out of time (happens if you put it in with the #1 tdc on the exhaust stroke)

#3

Thenotch in the hex key needs to be in the 4 o'clock position, with the #1 piston at TDC on the compression stroke. There should be a timing mark on the front of the timing chain cover that lines up with a notch on the back side of the crank pulley, it is out of view but you can feel it and line it up by touch. Don't do what I did and put the cam pos sensor in 180* out of time (happens if you put it in with the #1 tdc on the exhaust stroke)

I don't have that notch on the new motor. I'm glad you said 4 o-clock.

#4

Former Vendor

iTrader: (3)

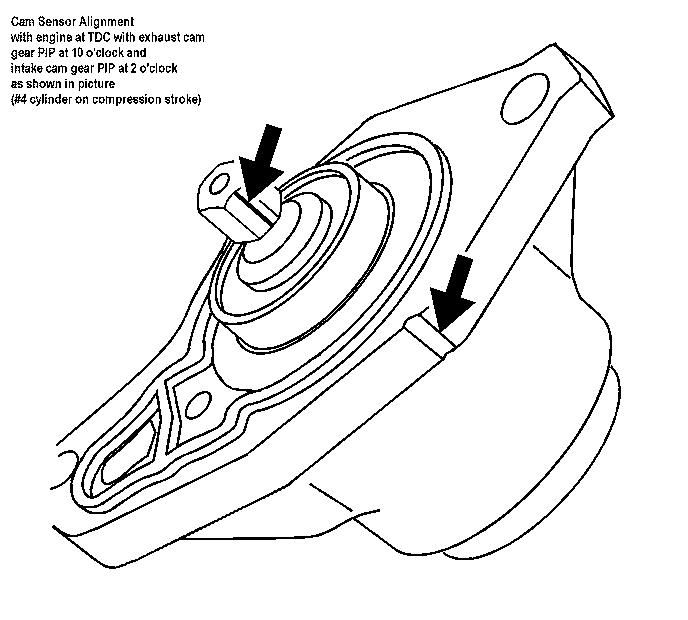

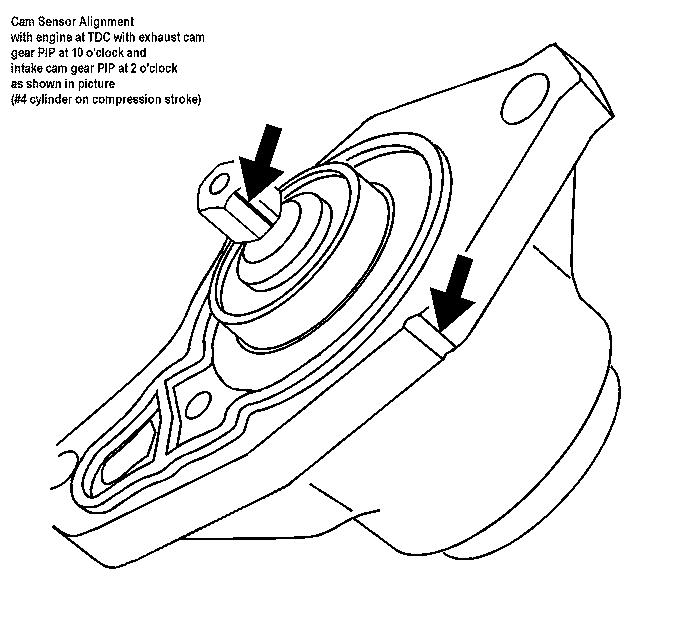

put the crank pulley lined up with mark at front, and # 4 cylinder at tdc valves closed.

take out cps unit and line up mark on hex with the exterior casting line on the outside of the unit. do not line it up with any inside marks ( there is one)

install. pull back and check the sensor hasnot moved as you inserted it. if it has realign and try again.

when its lined up, but bolts back in, clean up oil that has leaked out u r done.

take out cps unit and line up mark on hex with the exterior casting line on the outside of the unit. do not line it up with any inside marks ( there is one)

install. pull back and check the sensor hasnot moved as you inserted it. if it has realign and try again.

when its lined up, but bolts back in, clean up oil that has leaked out u r done.

#5

^I've done these instructions to a T and redid it to make sure. The code still came back after a little driving. I just don't get it.

I've been researching more about this Saab motor.

I've learned the Saab B207R has a hex key as the hex key spins a vacuum device(rather than a CPS) to create energy for the Master Cylinder. It's uses a eccentric system with the spark plugs and Coil Packs to sense Ionization of particles. AKA piston's firing. It's also took the crank position sensor and sent it to the DIC and 1/2'd the frequency and resent the information as Camshaft position. These's cars won't even attempt to start if the crank position sensor is broken.

It still doesn't make sense why the Hex I'm using no matter how it's timed it wrong.

I'm wondering if the Cam Gear/Cams being different make it so the sensor always believe's it wrong. That's what I'm currently trying to research.

Let me pick at your brain some too. Anyone able to chime in on this?

I need to get this fixed, I'm getting some shitty star-ups and heavy backfires. Sounds badass yes, but I go def in my left ear for about 10 seconds also. Not good.

I've been researching more about this Saab motor.

I've learned the Saab B207R has a hex key as the hex key spins a vacuum device(rather than a CPS) to create energy for the Master Cylinder. It's uses a eccentric system with the spark plugs and Coil Packs to sense Ionization of particles. AKA piston's firing. It's also took the crank position sensor and sent it to the DIC and 1/2'd the frequency and resent the information as Camshaft position. These's cars won't even attempt to start if the crank position sensor is broken.

It still doesn't make sense why the Hex I'm using no matter how it's timed it wrong.

I'm wondering if the Cam Gear/Cams being different make it so the sensor always believe's it wrong. That's what I'm currently trying to research.

Let me pick at your brain some too. Anyone able to chime in on this?

I need to get this fixed, I'm getting some shitty star-ups and heavy backfires. Sounds badass yes, but I go def in my left ear for about 10 seconds also. Not good.

#6

Sounds honestly like you are a bit off with your cam hex. When mine was way off(180* out) it would try to start but then just have crazy loud back fires. I would check again the cps, and I would also check the timing once again of the cams themselves. The car will run with them being a tooth off.

#7

Super Moderator

iTrader: (3)

Thenotch in the hex key needs to be in the 4 o'clock position, with the #1 piston at TDC on the compression stroke. There should be a timing mark on the front of the timing chain cover that lines up with a notch on the back side of the crank pulley, it is out of view but you can feel it and line it up by touch. Don't do what I did and put the cam pos sensor in 180* out of time (happens if you put it in with the #1 tdc on the exhaust stroke)

the propper way to time the cps is as follows

bring number 4cyl up on compression tdc align the timing mark on the hex wheel with the notch on the cpa housing and install

The following users liked this post:

07redrocketss/sc (12-15-2019)

#8

Tried it that way, threw cam position out of sync code. Refer to chapter 6 page 20 of the GM LSJ Build book and it describes it as I did and it got rid of the code I was throwing.

#11

Well it's official. I did this exactly to your specs. TDC Cyl 4 Valve Closed, even made sure cyl was making pressure with a gauge. Hell, I took off my Valve-Cover to make sure they were closed. Had battery disconnected. Still wasn't a perfect start and later on after 2 more restarts the light came back on. Will need to see what the code is in the morning. My tuner says he has a GM tool to "re-set" the sensor. So we will try that and see how it goes.

#13

If you keep throwing the code I would check your cam timing. If your cam timing is off you can put sensor in correctly and it will still throw the code.

When you install the hex key section of the sensor i find that it is easiest to take out the electrical sensor and put your finger in the hole to stop the hex key from rotating.

When you install the hex key section of the sensor i find that it is easiest to take out the electrical sensor and put your finger in the hole to stop the hex key from rotating.

#14

Are your cam gears adjustable? If they are you need to re-position the hex key in the end of the camshaft in some situations to ensure that it is in the correct position.

#15

Former Vendor

iTrader: (3)

If you keep throwing the code I would check your cam timing. If your cam timing is off you can put sensor in correctly and it will still throw the code.

When you install the hex key section of the sensor i find that it is easiest to take out the electrical sensor and put your finger in the hole to stop the hex key from rotating.

When you install the hex key section of the sensor i find that it is easiest to take out the electrical sensor and put your finger in the hole to stop the hex key from rotating.

#16

Just saying try it the way I described it. I was having the same issue, re timed my **** like a hundred times, until i did it the way the GM LSJ Build book said to do it a Vaola, code gone runs perfect.

#17

Senior Member

I do believe there is one other connector you can mix up with this one. I cant remember which one it is, but I would definitely re-check all your timing also. It's also pretty easy to get it off by a notch. that thing spins so easy if u just barely touch it, so be careful not to let it touch anything when you install it.

#18

Junior Member

iTrader: (3)

Just checked the build book and that indeed talks about lining up the "internal notch" at the 4 o'clock position on TDC compression stroke #1. Does that internal notch correspond with the outside allignment marks?

The OP has Saab cams fitted and although these have a hex key installed for driving the vacuum pump, but that does not mean their position is timed right for the LSJ cam sensor! (btw, CAM sensor has a unique connector in the LSJ engine loom)

#19

^^

Even though they are 207r cams it should not make a difference to the PCM. All the PCM is looking for is that the signal from the cam sensor matches what is referanced off where the crank is. The whole system assumes that the cams are mechanicly timed properly, and that the CPS is installed at the proper time as well.

It does not allign with that mark using the Build Book method

Even though they are 207r cams it should not make a difference to the PCM. All the PCM is looking for is that the signal from the cam sensor matches what is referanced off where the crank is. The whole system assumes that the cams are mechanicly timed properly, and that the CPS is installed at the proper time as well.

It does not allign with that mark using the Build Book method

#20

Junior Member

iTrader: (3)

^^

Even though they are 207r cams it should not make a difference to the PCM. All the PCM is looking for is that the signal from the cam sensor matches what is referanced off where the crank is. The whole system assumes that the cams are mechanicly timed properly, and that the CPS is installed at the proper time as well.

It does not allign with that mark using the Build Book method

Even though they are 207r cams it should not make a difference to the PCM. All the PCM is looking for is that the signal from the cam sensor matches what is referanced off where the crank is. The whole system assumes that the cams are mechanicly timed properly, and that the CPS is installed at the proper time as well.

It does not allign with that mark using the Build Book method

Have a spare cam sensor and will check if the Build book notch method ( @ TDC #1) is 180° opposite of the allignment markings (@ TDC #4)

#22

Good luck. I have the same problem and now my car wont start. At firts I mis time my cam sensor and it would startand bak fire. After I retime my cam sensor it would only crank but not.start. Immma take to a auto electric mechanic soon

#23

This way works for sure, I have a running car as proof. I tried it the other way and no dice.

#24

Are you sure its timed at the correct #1 TDC, If its at the Exhaust TDC then its not going to start at all. If you take your passanger wheel and wheel well off to access the crank pulley, there is a timing mark on the front of the timing cover that a notch on the back side of the crank pulley lines up with. You won't see it but can definately feel it with your finger tip. once the notch and the mark line up then #1 is at compression TDC, with engine in that configuration you can now set the cam pos timing in the 4 o'clock position.

This way works for sure, I have a running car as proof. I tried it the other way and no dice.

This way works for sure, I have a running car as proof. I tried it the other way and no dice.

Someone stated above and it makes sense. That the Saab cams have a hex insert, but the angle/direction of it might not even be make to ANY 'Spec.' They may have just made the whole for the Saabs to use for their vacuum line as the Saab doesn't use this hex for any timing needs.