how to time the engine

#26

Cliff notes

-You do NOT need to time the neutral balance shaft / water pump chain

-The new hydraulic tensioner does NOT need any "setting", bolt in and go

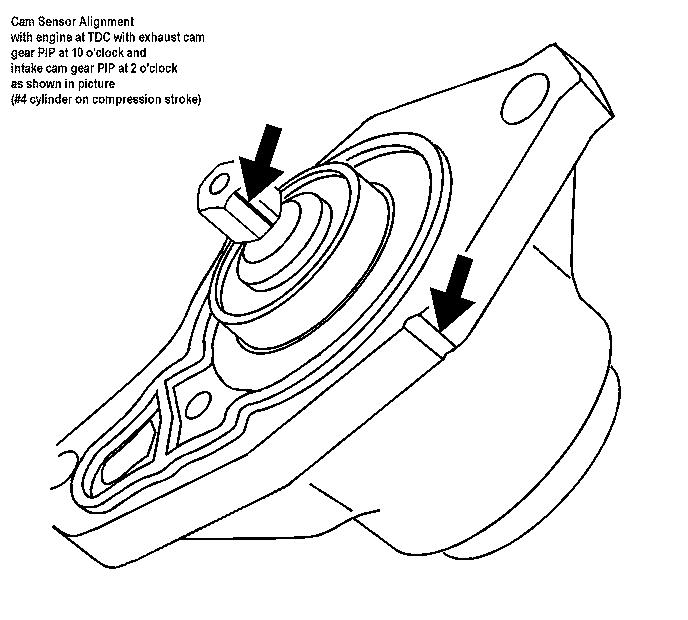

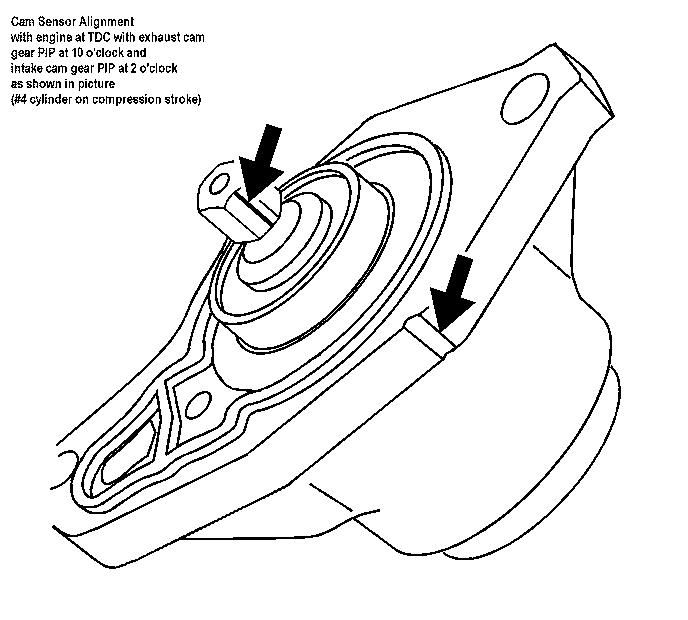

-Turn cylinder 1 (closest to chain) to TDC (crank keyway should be roughly 12ok

-The cam gears get put on with the "EXT" triangle pointed the same way as the lobes for cylinder 2

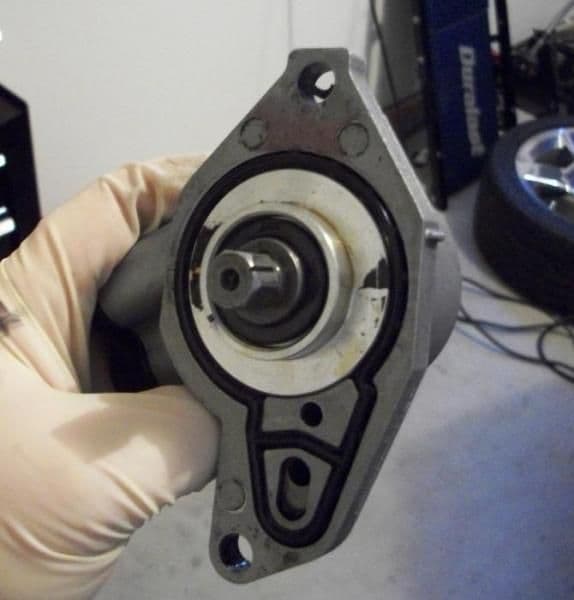

-the best can angle for putting the chain on is intake cam "INT" triangle pointed to 2ok and exhaust cam "EXT" triangle pointed to 11ok (do NOT rotate cams with engine at TDC)

-new chain from CED had black link for crank and exhaust and black with yellow link on each side for intake

-line up marks on the intake and crank with the corresponding links on the chain

-take an open end wrench and turn the exhaust cam (standing on passenger side looking from cylinder 1-4 counter clockwise slightly till the mark on the chain lines up with the cam mark

-the exhaust cam should be roughly at 10ok, intake at 2ok, crank keyway at 12ok and mark on the crank 5ok

-You do NOT need to time the neutral balance shaft / water pump chain

-The new hydraulic tensioner does NOT need any "setting", bolt in and go

-Turn cylinder 1 (closest to chain) to TDC (crank keyway should be roughly 12ok

-The cam gears get put on with the "EXT" triangle pointed the same way as the lobes for cylinder 2

-the best can angle for putting the chain on is intake cam "INT" triangle pointed to 2ok and exhaust cam "EXT" triangle pointed to 11ok (do NOT rotate cams with engine at TDC)

-new chain from CED had black link for crank and exhaust and black with yellow link on each side for intake

-line up marks on the intake and crank with the corresponding links on the chain

-take an open end wrench and turn the exhaust cam (standing on passenger side looking from cylinder 1-4 counter clockwise slightly till the mark on the chain lines up with the cam mark

-the exhaust cam should be roughly at 10ok, intake at 2ok, crank keyway at 12ok and mark on the crank 5ok

#28

Crap I cant get my ATI oversized super damper to go on...I will have to pull the timing cover again to see what is holding it up, eithor the oil pump or the crank shaft...

On a side note, what did you guys to to torque the crank pulley bolt down, keeping the engine from turning over and what not with the engine in the car?

On a side note, what did you guys to to torque the crank pulley bolt down, keeping the engine from turning over and what not with the engine in the car?

#29

Senior Member

iTrader: (8)

Crap I cant get my ATI oversized super damper to go on...I will have to pull the timing cover again to see what is holding it up, eithor the oil pump or the crank shaft...

On a side note, what did you guys to to torque the crank pulley bolt down, keeping the engine from turning over and what not with the engine in the car?

On a side note, what did you guys to to torque the crank pulley bolt down, keeping the engine from turning over and what not with the engine in the car?

Last edited by c130aviator; 05-12-2013 at 11:31 PM.

#31

Member

iTrader: (4)

This all sounds pretty simple...

A couple questions about this all.

-The build book talks about using assembly lubricant on all the bolt faces to get a better torque reading....does it matter what kind?

-I dont have a dial indicator for my socket. Can you just eyeball the degrees over torque?

-Best way to torque the crank pulley given its going to turn?

-Basically it goes like this...Bring piston 1 to tdc. Both intake and exhaust valves should be closed. Disassemble, and then re-assemble everything making sure all the colored links and marks line up.

So basically you cant screw this up if the links line up and piston 1 was at tdc?

A couple questions about this all.

-The build book talks about using assembly lubricant on all the bolt faces to get a better torque reading....does it matter what kind?

-I dont have a dial indicator for my socket. Can you just eyeball the degrees over torque?

-Best way to torque the crank pulley given its going to turn?

-Basically it goes like this...Bring piston 1 to tdc. Both intake and exhaust valves should be closed. Disassemble, and then re-assemble everything making sure all the colored links and marks line up.

So basically you cant screw this up if the links line up and piston 1 was at tdc?

#33

New Member

iTrader: (1)

Join Date: 07-08-10

Location: Covington, Indiana

Posts: 151

Likes: 0

Received 0 Likes

on

0 Posts

i took the little black plate off the bell housing and had a friend hold the fly wheel with a screw driver and that kept the crank from turning while installing the balancer. best way to do it? eh prolly not, but it worked for me.

#34

This all sounds pretty simple...

A couple questions about this all.

-The build book talks about using assembly lubricant on all the bolt faces to get a better torque reading....does it matter what kind?

-I dont have a dial indicator for my socket. Can you just eyeball the degrees over torque?

You could or like stated buy one to do it right

-Best way to torque the crank pulley given its going to turn?

I am not sure, I will try the blocking the fly wheel, or another idea i had was to take some plastic or nylon string and fill cylinder #1 and then turn it to DTC to wedge the piston

-Basically it goes like this...Bring piston 1 to tdc. Both intake and exhaust valves should be closed. Disassemble, and then re-assemble everything making sure all the colored links and marks line up.

almost, the exhaust cam needs to be turned a bit with a 15/16 iicr to get it to match up with the mark on the chain. Do what I said above, put the mark on the crank and intake cam, then use the wrench to turn over the exhaust cam. if you are standing on the passenger side of the car you turn it counter clockwise, this will also get rid of the slack between the crank and intake cam and the slack from between the cams, then bolt your guides back on (coat them with assembly lube) and then install new chain tensioner

So basically you cant screw this up if the links line up and piston 1 was at tdc?

You can... I suggest going over and rechecking everything again or 2 times just to make sure

A couple questions about this all.

-The build book talks about using assembly lubricant on all the bolt faces to get a better torque reading....does it matter what kind?

-I dont have a dial indicator for my socket. Can you just eyeball the degrees over torque?

You could or like stated buy one to do it right

-Best way to torque the crank pulley given its going to turn?

I am not sure, I will try the blocking the fly wheel, or another idea i had was to take some plastic or nylon string and fill cylinder #1 and then turn it to DTC to wedge the piston

-Basically it goes like this...Bring piston 1 to tdc. Both intake and exhaust valves should be closed. Disassemble, and then re-assemble everything making sure all the colored links and marks line up.

almost, the exhaust cam needs to be turned a bit with a 15/16 iicr to get it to match up with the mark on the chain. Do what I said above, put the mark on the crank and intake cam, then use the wrench to turn over the exhaust cam. if you are standing on the passenger side of the car you turn it counter clockwise, this will also get rid of the slack between the crank and intake cam and the slack from between the cams, then bolt your guides back on (coat them with assembly lube) and then install new chain tensioner

So basically you cant screw this up if the links line up and piston 1 was at tdc?

You can... I suggest going over and rechecking everything again or 2 times just to make sure

#36

Super Moderator

iTrader: (3)

Crap I cant get my ATI oversized super damper to go on...I will have to pull the timing cover again to see what is holding it up, eithor the oil pump or the crank shaft...

On a side note, what did you guys to to torque the crank pulley bolt down, keeping the engine from turning over and what not with the engine in the car?

On a side note, what did you guys to to torque the crank pulley bolt down, keeping the engine from turning over and what not with the engine in the car?

mark the end of the crank with the key location line it press it on use a longer bolt to start it and you may want to start the front cover on the dampner

#38

Nope. I was careful and watched the chain as I torqued the dampener bolt. Nothing looked to stretch or budge at all.

They also sell a tool specifically made to prevent any rotation why tightening the dampener bolt. It was shown in my Haynes Manual.

They also sell a tool specifically made to prevent any rotation why tightening the dampener bolt. It was shown in my Haynes Manual.

Last edited by Staged07SS; 05-13-2013 at 09:44 AM.

Thread

Thread Starter

Forum

Replies

Last Post

09BlkCrusader

Parts

30

09-09-2015 04:47 PM

Adam144

Problems/Service/Maintenance

5

09-03-2015 07:48 PM