Have any of you guys ever cut this off?

#1

Senior Member

Thread Starter

Have any of you guys ever cut this off?

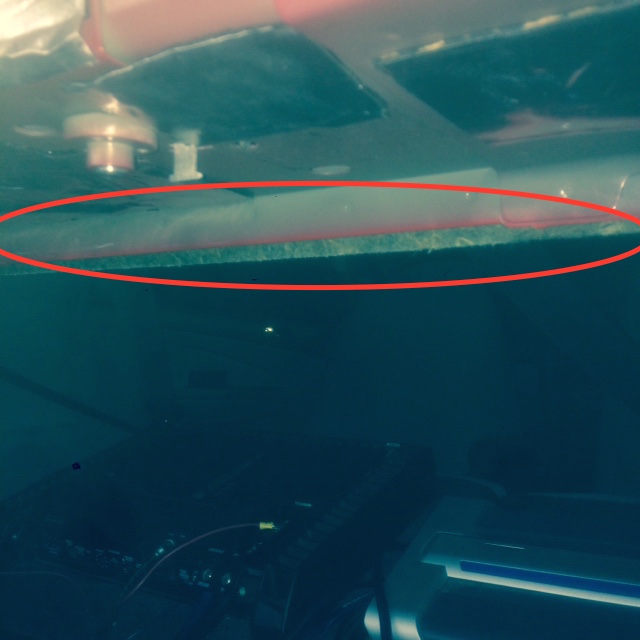

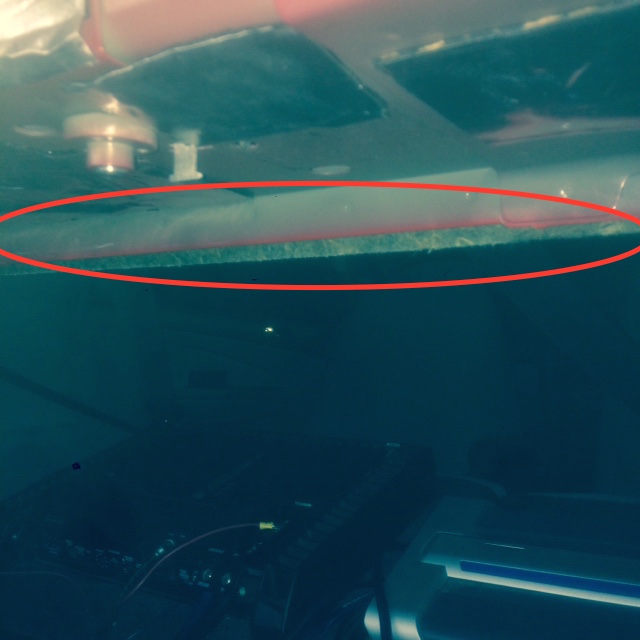

Long story short a few years ago I had a custom box built that wouldn't fit in through the trunk, and only fit through the back seats with like a quarter inch to spare on all sides. I just fabricated a solid wood floor in my trunk out of 1/2" plywood. I had everything planned out, there would be the back piece by the back seats where the sub would sit with all the wires routed underneath, then there are 2 separate pieces at the rear of the trunk that can be taken out to access the battery and spare tire. I didn't take into consideration the height of the sub box when I was making the floor so now this little half inch piece of metal, which servers no purpose i think, is keeping me from pushing the sub all the way back to the rear seat. In turn, it ***** up all the measurements i did due to the fact that the sub box is overlapping the 2 rear pieces by a few inches which makes it a MAJOR hassle to get to the battery/spare since the sub and box together probably weigh about 70lbs. If I can just cut maybe a quarter inch off this thing I will be able to slide the sub back all the way and all my problems will be solved. So, has anyone else done this? And if so, how? I am thinking of using a reciprocating saw with a metal cutting blade but wanted some input first. Any help appreciated.

#5

Senior Member

Thread Starter

#7

Senior Member

Thread Starter

Ah I see what you're saying. Id prefer to just bend it if that has worked for others so I don't have to deal with the hassle of reconnecting the 2 pieces. Between the making/carpeting/padding the new trunk, dealing with routing 3 0 gauge, and 2 4 gauge wires and getting the box/sub back in the trunk I just want to fix this the easiest way possible so I can be done with it.

#10

Senior Member

Thread Starter

I may try this as well. I pretty much need it to be bent 90 degrees so its flat against the bottom of the rear deck

#11

We got the JL 12w7 HO wedge in the trunk, and a 4cube net @ 32hz dual 10l7 box in through the back seats. obviously not at the same time. both had zero clearance, and mashed the carpet haha.

When I ran my 18" HDC318, I had to build out a frame in the backseat haha. That was awesome on BC2000D

Now the car is gutted including radio/speaker delete -__-

When I ran my 18" HDC318, I had to build out a frame in the backseat haha. That was awesome on BC2000D

Now the car is gutted including radio/speaker delete -__-

#15

Senior Member

Thread Starter

I used a rubber mallet for the middle of it, had to use a real hammer to get the edges where it curves though. Also had to cut the rear deck lid about a half inch high to let the box slide through which was a pain in the ass. However, it is all done thank god. thanks for the suggestions!

Thread

Thread Starter

Forum

Replies

Last Post

Moderator

Moderator