LIPSTICK's 800hp first LNF compound turbo/engine build!

#101

Senior Member

Join Date: 06-13-08

Location: Waltham MA

Posts: 1,907

Likes: 0

Received 0 Likes

on

0 Posts

#102

Senior Member

Thread Starter

you should be an architect!!!

but seriously.............

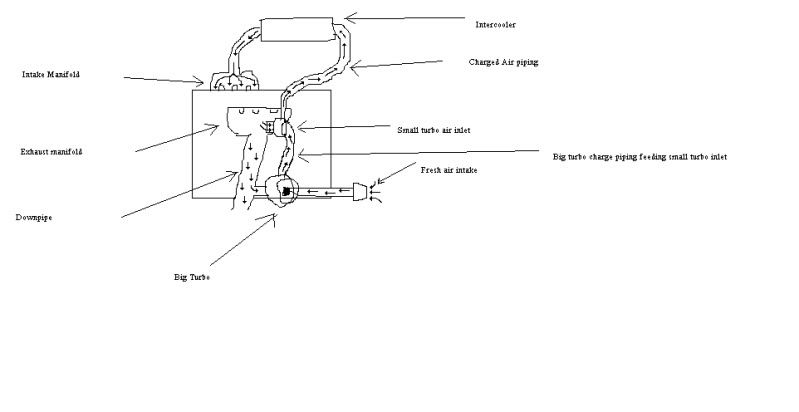

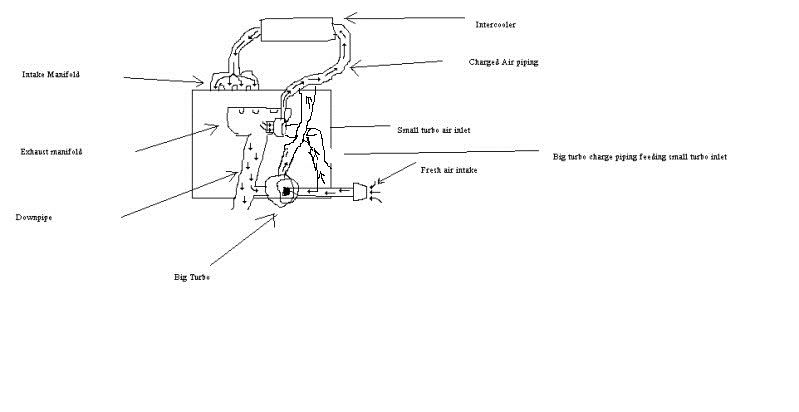

that will be similar to my set-up......EXCEPT that there will be a 60mm wastegate on the downpipe in between the small turbo and big turbo.

The downpipe and 60mm wastegate.......all of their exhaust gases will move directly to the big turbo.

On your picture........the downpipe is not FULLY CONNECTED to the big turbo. It should be all connected to the big turbo. All those exhaust gases should be routed DIRECTLY to the big turbo....and NOTHING ELSE.....

there will be another smaller wastegate on the exhaust side of the big turbo to release extra gases..........that will go to the exhaust pipe (system) of my car

but seriously.............

that will be similar to my set-up......EXCEPT that there will be a 60mm wastegate on the downpipe in between the small turbo and big turbo.

The downpipe and 60mm wastegate.......all of their exhaust gases will move directly to the big turbo.

On your picture........the downpipe is not FULLY CONNECTED to the big turbo. It should be all connected to the big turbo. All those exhaust gases should be routed DIRECTLY to the big turbo....and NOTHING ELSE.....

there will be another smaller wastegate on the exhaust side of the big turbo to release extra gases..........that will go to the exhaust pipe (system) of my car

Last edited by SKY888; 08-23-2010 at 10:10 PM.

#103

Senior Member

Join Date: 06-13-08

Location: Waltham MA

Posts: 1,907

Likes: 0

Received 0 Likes

on

0 Posts

you should be an architect!!!

but seriously.............

that will be similar my set-up......except that there will be a 60mm wastegate on the downpipe in between the small turbo and big turbo.

The downpipe and 60mm wastegate.......all of their exhaust gases will move directly to the big turbo

and there will be another smaller wastegate on the exhaust side of the big turbo to release extra gases..........that will go to the exhaust pipe

but seriously.............

that will be similar my set-up......except that there will be a 60mm wastegate on the downpipe in between the small turbo and big turbo.

The downpipe and 60mm wastegate.......all of their exhaust gases will move directly to the big turbo

and there will be another smaller wastegate on the exhaust side of the big turbo to release extra gases..........that will go to the exhaust pipe

#104

Senior Member

Thread Starter

I updated my thread response to make it more clear.

Please join my facebook account "antonio sky".....so you will be updated when the dyno tuning begins

Fred is finishing up with Project Scarab. BTF is currently working on the compound turbo set-up.

Please join my facebook account "antonio sky".....so you will be updated when the dyno tuning begins

Fred is finishing up with Project Scarab. BTF is currently working on the compound turbo set-up.

#105

Former Vendor

You guys should stop using psi and start using pressure ratios when calculating a compound turbo setup. Once you are familiar with pressure ratios, it becomes very easy to design a compound turbo setup. Basically, you start with a single turbo setup using the small turbo fitted to the 2 liter motor. Design it to run efficiently with only the small turbo. Once you have an idea of the power curve with the small turbo only, think about turbocharging this setup again as if it was an NA motor. In other words, choose the large turbo based on the airflow/horsepower of the already turbocharged motor. For example, if you are already making 300whp, you can quickly spool a pretty big turbo otherwise much too large for a 2 liter motor.

When using compressor maps and calculating overall boost ratios on a compound setup, you can't just add boost numbers together. Two turbos flowing in series, both running at 2:1 pressure ratios (14.7psi each) actually puts 44.1 psi in the intake manifold or a pressure ratio of 4:1. Remember to add in atmospheric pressure to find absolute pressure before calculating a pressure ratio and subtract it when converting back to boost numbers.

When using compressor maps and calculating overall boost ratios on a compound setup, you can't just add boost numbers together. Two turbos flowing in series, both running at 2:1 pressure ratios (14.7psi each) actually puts 44.1 psi in the intake manifold or a pressure ratio of 4:1. Remember to add in atmospheric pressure to find absolute pressure before calculating a pressure ratio and subtract it when converting back to boost numbers.

#106

Senior Member

Thread Starter

You guys should stop using psi and start using pressure ratios when calculating a compound turbo setup. Once you are familiar with pressure ratios, it becomes very easy to design a compound turbo setup. Basically, you start with a single turbo setup using the small turbo fitted to the 2 liter motor. Design it to run efficiently with only the small turbo. Once you have an idea of the power curve with the small turbo only, think about turbocharging this setup again as if it was an NA motor. In other words, choose the large turbo based on the airflow/horsepower of the already turbocharged motor. For example, if you are already making 300whp, you can quickly spool a pretty big turbo otherwise much too large for a 2 liter motor.

When using compressor maps and calculating overall boost ratios on a compound setup, you can't just add boost numbers together. Two turbos flowing in series, both running at 2:1 pressure ratios (14.7psi each) actually puts 44.1 psi in the intake manifold or a pressure ratio of 4:1. Remember to add in atmospheric pressure to find absolute pressure before calculating a pressure ratio and subtract it when converting back to boost numbers.

When using compressor maps and calculating overall boost ratios on a compound setup, you can't just add boost numbers together. Two turbos flowing in series, both running at 2:1 pressure ratios (14.7psi each) actually puts 44.1 psi in the intake manifold or a pressure ratio of 4:1. Remember to add in atmospheric pressure to find absolute pressure before calculating a pressure ratio and subtract it when converting back to boost numbers.

hi matt.....if you look at my long posts .....I started talking about pressure ratios.

and I also mentioned stating that my engine and gt28, to be considered as a bigger engine......and to seperate the big turbo.

anyways, as what I mentioned on my posts, 2:1 PR is very ideal, but I believe I am not going that level. Maybe lower...to get around 35psi (not 44.1 psi).

I know that some members might not be understanding presure ratios yet, on top of that adding the compound turbo set-up complexity.............and that's why as much as possible I didn't really go talking about PRs....and talk about psi instead to make it more easy to understand by most members....and less confusing.

but I guess you are right, I should start talking about PRs to make it less confusing to people who are more knowledgeable about turbo computations/terminologies. I just wana avoid more confusion for other members.......

thats all

#107

I just wasn't getting that the big turbo blows into the smaller one. Knowing that, it makes sense that boost is multiplied rather than added.

I'm having trouble understanding how you can eventually fit 600+hp worth of air through the gt2871 compressor though. How much air can you actually move through the smaller compressor this way? What I'm getting at is once the GT40 spools up, does the smaller compressor wheel not become somewhat of a restriction? It seems like the GT40 could breath enough to spin the spin the smaller compressor faster than the turbine could, but that thought breaks the laws of conservation of energy lol.

I now understand the direction of the airflow, but help me understand the details. Are we essentially multiplying the airflow of the smaller turbo by the PR of the bigger turbo, since that PR is basically the smaller turbo system's new "atmospheric"? For example if you run a PR of 1.5 on the GT40r, you get an ~50% more airflow/power out of the GT2871 as a system? All the while having all the early torque of the GT2871 while the GT40 is not boosting?

I'm having trouble understanding how you can eventually fit 600+hp worth of air through the gt2871 compressor though. How much air can you actually move through the smaller compressor this way? What I'm getting at is once the GT40 spools up, does the smaller compressor wheel not become somewhat of a restriction? It seems like the GT40 could breath enough to spin the spin the smaller compressor faster than the turbine could, but that thought breaks the laws of conservation of energy lol.

I now understand the direction of the airflow, but help me understand the details. Are we essentially multiplying the airflow of the smaller turbo by the PR of the bigger turbo, since that PR is basically the smaller turbo system's new "atmospheric"? For example if you run a PR of 1.5 on the GT40r, you get an ~50% more airflow/power out of the GT2871 as a system? All the while having all the early torque of the GT2871 while the GT40 is not boosting?

#108

Senior Member

Join Date: 01-12-09

Location: Illinois

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

I just wasn't getting that the big turbo blows into the smaller one. Knowing that, it makes sense that boost is multiplied rather than added.

I'm having trouble understanding how you can eventually fit 600+hp worth of air through the gt2871 compressor though. How much air can you actually move through the smaller compressor this way? What I'm getting at is once the GT40 spools up, does the smaller compressor wheel not become somewhat of a restriction? It seems like the GT40 could breath enough to spin the spin the smaller compressor faster than the turbine could, but that thought breaks the laws of conservation of energy lol.

I now understand the direction of the airflow, but help me understand the details. Are we essentially multiplying the airflow of the smaller turbo by the PR of the bigger turbo, since that PR is basically the smaller turbo system's new "atmospheric"? For example if you run a PR of 1.5 on the GT40r, you get an ~50% more airflow/power out of the GT2871 as a system? All the while having all the early torque of the GT2871 while the GT40 is not boosting?

I'm having trouble understanding how you can eventually fit 600+hp worth of air through the gt2871 compressor though. How much air can you actually move through the smaller compressor this way? What I'm getting at is once the GT40 spools up, does the smaller compressor wheel not become somewhat of a restriction? It seems like the GT40 could breath enough to spin the spin the smaller compressor faster than the turbine could, but that thought breaks the laws of conservation of energy lol.

I now understand the direction of the airflow, but help me understand the details. Are we essentially multiplying the airflow of the smaller turbo by the PR of the bigger turbo, since that PR is basically the smaller turbo system's new "atmospheric"? For example if you run a PR of 1.5 on the GT40r, you get an ~50% more airflow/power out of the GT2871 as a system? All the while having all the early torque of the GT2871 while the GT40 is not boosting?

#109

Senior Member

Thread Starter

it does seem like the small turbo will be a restriction, but in the end its NOT. It doesn't know what you're force feeding it since it only cares about moving volume and can't tell what the density is. We all know what hapens to a turbo between sea level and 5000 feet, this is like going 5000 feet below sea level

#110

Senior Member

Thread Starter

To use some conveniently round numbers, lets say my small turbo is rated at 500 cfm, which ends up being 50 lbs/min when fed air at atmospheric pressure. If you then use the big turbo to raise the pressure to double atmospheric pressure, or 15 psi boost, the density of that air is doubled. That same 500 cfm, which the small turbo still moves, now weighs 100 lbs/min. The small turbo still moved the same exact volume of air, but with it being twice as dense, its twice the amount of air, and provides twice the horsepower. But it still only takes roughly the same drive power to move that air, as evidenced in the law of back pressure. This is where all the magic happens.

the point to remember is that the small turbo is not moving any more VOLUME of air that it otherwise would.

the point to remember is that the small turbo is not moving any more VOLUME of air that it otherwise would.

#111

Senior Member

Join Date: 01-12-09

Location: Illinois

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

Ok, thats said, I have a question to ask now, lol.

If it doesn't care about density, and only volume... why are turbo's rated in flow @ lbs/min?? Lbs/min would be a volume, sure, but it would depend on density. That would be like saying I could move 40 bricks an hour, it doesn't say that I can only move 40, 5 lb bricks an hour, so when I have to move 40, 100 lb bricks per hour, I am really gonna burn up.

So, in my head, air at a higher pressure would thus have a higher density, even at the same volume. That said, the restriction of the air flow would be greater, obviously. So, when you think of the forces acting on the compressor wheel, it seems like it would go backward. Its obvious I am over thinking this, but thats usually how I learn things, lol.

I guess... since air compresses rather easily, the density of the air might not be changed significantly, but it would still be able to cram into the same volume?

Weird.

If it doesn't care about density, and only volume... why are turbo's rated in flow @ lbs/min?? Lbs/min would be a volume, sure, but it would depend on density. That would be like saying I could move 40 bricks an hour, it doesn't say that I can only move 40, 5 lb bricks an hour, so when I have to move 40, 100 lb bricks per hour, I am really gonna burn up.

So, in my head, air at a higher pressure would thus have a higher density, even at the same volume. That said, the restriction of the air flow would be greater, obviously. So, when you think of the forces acting on the compressor wheel, it seems like it would go backward. Its obvious I am over thinking this, but thats usually how I learn things, lol.

I guess... since air compresses rather easily, the density of the air might not be changed significantly, but it would still be able to cram into the same volume?

Weird.

#112

Senior Member

Thread Starter

damn, Matt...don't confuse yourself. You already have a good idea.......and pls dont go backwards, anymore! You're making me confused as well! lol

why are turbos rated in flow @ lb/min? Mass Flow Rate (MFR) which is also expressed in lb/min. MFR can be physically measured, and in most cases very sufficient to estimate the mass flow in choosing a proper turbo for your engine set-up/horsepower needs......

why are turbos rated in flow @ lb/min? Mass Flow Rate (MFR) which is also expressed in lb/min. MFR can be physically measured, and in most cases very sufficient to estimate the mass flow in choosing a proper turbo for your engine set-up/horsepower needs......

#113

Senior Member

Ok, thats said, I have a question to ask now, lol.

If it doesn't care about density, and only volume... why are turbo's rated in flow @ lbs/min?? Lbs/min would be a volume, sure, but it would depend on density. That would be like saying I could move 40 bricks an hour, it doesn't say that I can only move 40, 5 lb bricks an hour, so when I have to move 40, 100 lb bricks per hour, I am really gonna burn up.

So, in my head, air at a higher pressure would thus have a higher density, even at the same volume. That said, the restriction of the air flow would be greater, obviously. So, when you think of the forces acting on the compressor wheel, it seems like it would go backward. Its obvious I am over thinking this, but thats usually how I learn things, lol.

I guess... since air compresses rather easily, the density of the air might not be changed significantly, but it would still be able to cram into the same volume?

Weird.

If it doesn't care about density, and only volume... why are turbo's rated in flow @ lbs/min?? Lbs/min would be a volume, sure, but it would depend on density. That would be like saying I could move 40 bricks an hour, it doesn't say that I can only move 40, 5 lb bricks an hour, so when I have to move 40, 100 lb bricks per hour, I am really gonna burn up.

So, in my head, air at a higher pressure would thus have a higher density, even at the same volume. That said, the restriction of the air flow would be greater, obviously. So, when you think of the forces acting on the compressor wheel, it seems like it would go backward. Its obvious I am over thinking this, but thats usually how I learn things, lol.

I guess... since air compresses rather easily, the density of the air might not be changed significantly, but it would still be able to cram into the same volume?

Weird.

#114

Former Vendor

Remember to look at the system with only the small turbo first. If this setup works, then adding a larger turbo to blow through the small turbo will never make the small turbo a restriction. It's like running a 2" charge tube and thinking that you can't make 500hp through a 2" tube that is 4 feet long. In the case of a naturally aspirated motor, this would be true. However, when the charge tube is flowing air at 25psi boost, you could easily make over 500hp with a 2" charge tube. The same goes for blowing through a turbo. When a turbo inlet is fed with compressed air, it can still compress it even more without any issue, whatsoever.

#115

Thank you gentlemen for the info/explainations. I think i get it 100% now, and am even more excited to see the results! I retract my previous statement about the boost split and being able to make the power. Your original boost split looks great and hopefully meet your goals!

On another note, what are the downsides to a this set up? The only one i see is cost - otherwise it's win across the board! You are going to have like a 6000+rpm wide torque band and excellent peak power How would you feel about this on a smaller scale - say a gt30r and the stock k04? If that's too far off topic it's cool i'll take it to PM

You are going to have like a 6000+rpm wide torque band and excellent peak power How would you feel about this on a smaller scale - say a gt30r and the stock k04? If that's too far off topic it's cool i'll take it to PM

On another note, what are the downsides to a this set up? The only one i see is cost - otherwise it's win across the board!

You are going to have like a 6000+rpm wide torque band and excellent peak power How would you feel about this on a smaller scale - say a gt30r and the stock k04? If that's too far off topic it's cool i'll take it to PM

You are going to have like a 6000+rpm wide torque band and excellent peak power How would you feel about this on a smaller scale - say a gt30r and the stock k04? If that's too far off topic it's cool i'll take it to PM

#116

Senior Member

Thread Starter

yes, cost is the only downside of a compound set-up......due to parts/labor/especially tuning.

It is an ultimate turbo set-up in my opinion. It is DRIVEABLE AND STREETABLE. It has a LINEAR power increase. You can race the car on almost any racing events: drag, autocross, drift, road race, time attack, gymkhana, and etc. It has such a wide powerband, and enough tq and top hp that you will need in any event.

matching turbos is almost a black art. I haven't seen any science behind matching turbos properly. Been talking to Marc of boost logic, and they've experienced a lot of power loss both down low and at the higher rpms during matching different turbos. Sometimes the small turbo is too small for the big turbo.....and the big turbo is too big for the small turbo. But you also have to avoid the turbos being too close in size (GT3071 and GT3076/GT3582). Too close will not give you a wider powerband.

Plus matching the turbos properly to a certain engine size is also a key.

I know that boost logic, after making the jump of increasing the size of both of their compound turbos.............greatly affected their tq and peak hp. They were not happy with the results.

I was actually planning before to use k04 and my gt35 to reach my 600whp ultimate goal. But EVERYBODY (who already did a compound set-up) that I talked to keven jewer, marc of boost logic, the guy from dsm, and another guy ........they all told me that the turbos will probably have a hard time achieving my goals. With 400-500whp......it will be achieavable. That's why I sold my turbo kit, and the brand new k04 that I have.

yes, with a smaller scale, and lower power goals.......the k04 and gt35 is "probably" a good choice combo. But again, it will be a trial and error, and see how the two turbos react to each other. It will definitely spool very quick!!!

It is an ultimate turbo set-up in my opinion. It is DRIVEABLE AND STREETABLE. It has a LINEAR power increase. You can race the car on almost any racing events: drag, autocross, drift, road race, time attack, gymkhana, and etc. It has such a wide powerband, and enough tq and top hp that you will need in any event.

matching turbos is almost a black art. I haven't seen any science behind matching turbos properly. Been talking to Marc of boost logic, and they've experienced a lot of power loss both down low and at the higher rpms during matching different turbos. Sometimes the small turbo is too small for the big turbo.....and the big turbo is too big for the small turbo. But you also have to avoid the turbos being too close in size (GT3071 and GT3076/GT3582). Too close will not give you a wider powerband.

Plus matching the turbos properly to a certain engine size is also a key.

I know that boost logic, after making the jump of increasing the size of both of their compound turbos.............greatly affected their tq and peak hp. They were not happy with the results.

I was actually planning before to use k04 and my gt35 to reach my 600whp ultimate goal. But EVERYBODY (who already did a compound set-up) that I talked to keven jewer, marc of boost logic, the guy from dsm, and another guy ........they all told me that the turbos will probably have a hard time achieving my goals. With 400-500whp......it will be achieavable. That's why I sold my turbo kit, and the brand new k04 that I have.

yes, with a smaller scale, and lower power goals.......the k04 and gt35 is "probably" a good choice combo. But again, it will be a trial and error, and see how the two turbos react to each other. It will definitely spool very quick!!!

Last edited by SKY888; 08-25-2010 at 07:49 AM.

#118

New Member

Join Date: 05-19-08

Location: Lake Zurich, IL

Posts: 118

Likes: 0

Received 0 Likes

on

0 Posts

Now let me ask you this... What would people do for a Compound set up on a V8??? Lets say a GMPP LSX Block for an example.. Would you combined the two headers? Or do something else?

#119

Senior Member

Join Date: 01-12-09

Location: Illinois

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

Well, its not AS common for people to compound a V motor, but if they did, yes they would combine the header.

#122

Senior Member

iTrader: (1)

he answered that post a couple posts back. I never thought about it before but he's right, the turbo only moves volume, not density. So if you imagine the area between the compressor blades is moving air at atmospheric density on the bigger turbo... the air becomes "charged or more dense" after the turbo which means in a given volume there are more air molecules. Now the small turbo sees this dense air and the dense air is moved by the compressor blades of the small turbo past it and on towards the engine. Does not necessarily mean its compressing it more... the only way a turbo becomes restrictive is by blocking the exhaust in the initial turbo lag zone. But again thats not what we are talking about here

#125

Former Vendor

The exhaust housing/wheel of the small turbo can become an issue, which is why the wastegate for the small turbo is spec'd so large. This in done in attempt to get the small turbo out of the way, in a sense.